DigiKey presents a three-part series highlighting the latest innovations in robotics, automation, connectivity, and cutting-edge technologies in the world of manufacturing. Join us as we explore how factories are becoming smarter and more complex to meet the rising demands of an ever-evolving world.

- SEASON 1

- SEASON 2

- SEASON 3

- SEASON 4

- SEASON 5

SEASON 1 IS POWERED BY

S1: EPISODE 1

Manufacturing at The Edge

In our first episode, we look at the rise of edge computing, which is bringing complex technologies like machine learning to the point of data capture, enabling faster and more responsive reactions to the data generated by sensors across the factory floor.

S1: EPISODE 2

The Rise of Robotics

In the second episode, we chronicle the rise of robotics in the manufacturing industry, and how new designs collaborate alongside human workers on the factory floor to create new, high-quality job opportunities across the industry.

S1: EPISODE 3

The Intersection of AI and IoT

In this episode of Factory Tomorrow, we look at how artificial intelligence applications can unlock the true potential of IoT and edge applications across manufacturing. Find out how real-time analytics, connected sensors, predictive maintenance, supply chain automation, and other process advancements are propelling the manufacturing industry forward into a new era.

Related Products

Banner Engineering

2170-DX80N9Q45VA-ND

Sensor Vibration/Temp Wireless

Banner Engineering

2170-SOLUTIONSKIT9-VIBE-ND

Wireless Vibration & Temp Kit

Banner Engineering

2170-S15C-MGP-KQ-ND

In-Line Data Converter

Banner Engineering

R90C IO-Link Hub

Signals into an IO-Link data stream compatible with other devices.

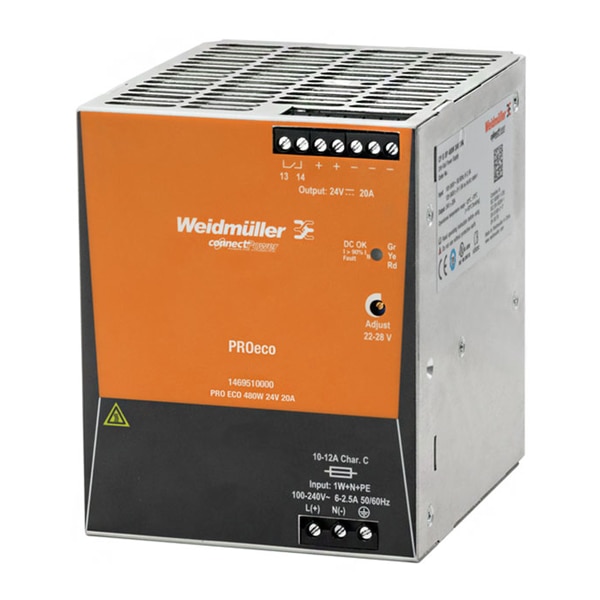

Weidmuller

281-7940111686-ND

IIOT Controller With Digital IO

Weidmuller

281-2580220000-ND

Switch Mode, PWR Supply 12V

Weidmuller

281-2730670000-ND

Surge Protection - OVP

Weidmuller

PROeco Single-Phase Power Supplies

Offers basic functions and delivers high performance and flexibility.

Additional Content

Predictive Maintenance Trends: Machine Learning

Predictive maintenance is becoming essential to the smart factory. The ability to accurately track machine performance helps manufacturers reduce wasted time and costs.

Remote Monitoring Field Device Level

Data from sensors was once difficult to access or completely unavailable. With the Industrial Internet of Things (IIoT), device-level data is now accessible to operators and plant managers.

Versatile DIN-Rail Supplies Fuel Industrial Automation Applications

Designers are able to specify an off-the-shelf solution to powering DIN-rail equipment, with the advantages of a ready-made module.

AppGuide, Industrial Control Product Selector

Use this product selector to help in picking the right solutions for the Industrial IoT.

Related Videos

SEASON 2 IS POWERED BY

In Factory Tomorrow Season 2 we explore the driving force behind Industry 4.0, and how do technologies like AI, edge computing, and connectivity transform the future of manufacturing? We visit with top experts in these fields, to discuss the answers to these questions, and learn how DigiKey and their partners are shaping the next major leap forward for manufacturing.

S2: EPISODE 1

Seeing Double

To meet rising global demand and navigate supply chain challenges, manufacturers must think ahead. Digital Twins allow for detailed hardware simulations that influence everything from manufacturing processes, to entire layouts of future factory floors. What's the next step for this technology, and how should modern manufacturers start investing into it today?

S2: EPISODE 2

The Show Must Go On

Whether it's issues with machinery, component shortages, or other potential challenges, manufacturing shutdowns are simply not an option. Today's factories must achieve system-wide visibility through the use of complex sensors and hardware designed to capture, monitor, and deliver key insights before issues arise.

S2: EPISODE 3

Thinking Outside the Box

Pioneers in the world of manufacturing are always thinking ahead and prototyping the future of technologies across the factory floor. In this episode, we visit one such location where cutting-edge manufacturing solutions are developed and conceptualized in real-time, providing us with a glimpse into tomorrow's manufacturing today.

Related Products

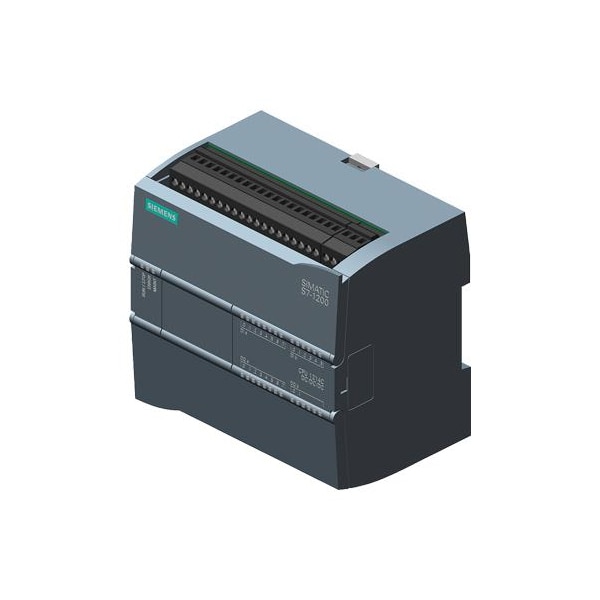

Siemens

SIMATIC S7-1200 Basic Controllers

Compact automation solutions with integrated communication and technology functions.

Siemens

SIMATIC Basic Panels

Simplifies the operation of simple machines and equipment.

Siemens

SITOP SEL1200/SEL1400 Selectivity Modules

Distribute the load current across 24 VDC load circuits and monitor them.

Siemens

SITOP PSU6200 Power Supply

Extremely high-performance power supply for 12 V, 24 V, and 48 V standard applications.

Schneider Electric

Easy TeSys Contactors

Designed to switch and protect the most common motor applications.

Schneider Electric

Easy TeSys Manual Motor Starters

Designed to control and protect motors.

Schneider Electric

Easy TeSys Thermal Overload Relays

Designed to protect AC circuits and motors.

Phoenix Contact

CAPAROC Electronic Circuit Breaker System

Designed for overcurrent protection in 12 V to 24 V applications

Phoenix Contact

PSRmodular Configurable Safety System

Flexible safety solution to monitor a machine or system.

Phoenix Contact

Industrial Case Systems: Enclosures for IoT Devices

ICE/heatsinks, free web-based thermal simulation using the online configurator, and more.

Phoenix Contact

BL2 BPC 1500 Series

Entry-level automation, small machine control, and IIoT applications.

Phoenix Contact

RIFLINE Pluggable Force-Guided Relays

Offer industrial multi-channel force-guided contacts in a narrow design

Additional Content

Programming PLCs: A Technical Summary with Siemens Examples

With the fourth industrial revolution and Industry 4.0, comprehensive and intelligent automation is defined by advanced controls, monitoring, and diagnostics.

The Digital Twin Concept and How It Works

Implementing the Digital Twin culture, which includes real-world and virtual product-life-cycle management software, reduces design cycle time, testing, and improves yields.

How to Select and Apply Electromechanical Contactors for Heavy-Duty Three-Phase AC Motors

EMCs are the best solution for frequent switching of heavy-duty loads such as large electric motors, but designers need to choose and implement with care.

Use Fine-Pitch Board-to-Board Connectors to Optimize System Packaging

When two or more pc boards must be used in a product, board-to-board connectors offer high-performance solutions to the electrical and mechanical pairing.

How to Use Single Pair Ethernet to Save Space and Weight While Improving Industrial IoT Performance

Use single pair Ethernet for bidirectional high-speed transmission of data and power to save space and weight in industrial and enterprise installations.

How to Ensure Safe and Efficient Modular BESS Deployments Using Pluggable Battery Pole Connectors

Use pluggable battery pole connectors rated for 1500 VDC and 120 A that meet UL 4128 and speed modular BESS installations.

Configure Industrial Sensors and Actuators Faster, Safely, and Reliably with Sensor Actuator Boxes

Automation engineers can reduce configuration time and ensure reliable connectivity between controllers and sensors/actuators using sensor actuator boxes.

How to Safely Incorporate Cobots in Industrial Workplaces

Safe robot-human collaboration requires application-specific risk assessment and system definition, and there are now technical specifications that provide guidance.

Related Videos

SEASON 3 IS POWERED BY

DigiKey presents a three-part series exploring how our suppliers are leveraging new forms of technology to design a sustainable future for manufacturing. Join us as we examine the latest innovations and best practices that are reducing waste, increasing efficiency, and promoting environmentally-friendly modes of production. From microgrids, to alternative sources of energy, to smart manufacturing systems and beyond.

S3: EPISODE 1

Reducing the Impact of Production

Manufacturing processes use roughly one-third of the world's energy. In this episode, we learn how manufacturers are taking advantage of alternative energy sources, creating microgrids, and harnessing emerging technology to offset the carbon footprint of their production processes to make a more sustainable future.

S3: EPISODE 2

Inspiring Change on the Factory Floor

As global demand continues to increase, automation technology has rapidly advanced to keep pace. However, as a result of this mass demand, new challenges have surfaced. This episode showcases the transformation of Schneider Electric's Lexington, Kentucky facility, which has been completely reimagined into a factory of the future. By examining this transformation, we can learn how it serves as a model for others in the industry looking to create more sustainable operations.

S3: EPISODE 3

Sustainable Manufacturing Techniques in Action

In this episode, we take a look at real-world examples of sustainable manufacturing and automation in action. We visit the companies that are leading the way in their field, and learn about the specific technologies and techniques they are using to minimize environmental impact.

Related Products

Panduit

Opti-Core™ Fiber Optic Cable

Schneider Electric

TeSys™ Island Communicating Motor Starters

Panduit

Nylon 612 Cable Ties

Schneider Electric

Surgelogic™ Square D IESE Surge Protector

Panduit

Control Panel Solutions for Reliable System Performance

Schneider Electric

Sustainable Manufacturing

Panduit

VeriSafe™ Absence of Voltage Tester

Schneider Electric

Harmony Safety Modules

Panduit

IndustrialNet™ M12 Cat 5e and Cat 6A Overmolded Cordsets

Schneider Electric

Altivar™ Soft Starter ATS480

Panduit

G5 Power Distribution Units

Schneider Electric

Altivar™ 212 Variable Speed Drives (VSD)

Panduit

Panduct® PanelMax™ Wiring Duct and Noise Shield

Schneider Electric

Modicon DIN Rail Power Supplies

Panduit

Plastic Solar Edge Clips

Schneider Electric

ATV320 Variable Frequency Drives (VFD)

Additional Content

Optimizing Cable Management to Ensure Safety and Efficiency in Utility Scale PV Systems

Utility-scale photovoltaic (PV) systems typically generate several megawatts (MW) of electricity and are key contributors to green energy and sustainability.

Empowered by Cutting-Edge Automation Technology: The Sustainable Journey

The demand for energy, the use of raw materials, and – particularly in metropolitan areas – the size of the land required are the most critical factors of industrial production.

How Automation is Helping U.S. Manufacturers Scale Semiconductor Manufacturing

Despite the critical nature of semiconductors, much of the world is dependent on undiversified and therefore vulnerable global supply chains.

Using Humidity and Temperature Sensors to Improve Sustainability in Greenhouses and HVAC Systems

Controlling humidity and temperature is essential in diverse environments like greenhouses, datacenters, offices, and industrial facilities.

The Basics of Motor Contactors and Their Application

Applications such as heating, ventilation, and air conditioning (HVAC), compressors, pumps, material handling, and packaging, require the safe deployment and control of large motors operating off high voltages and currents.

How to Select and Apply the Right Cable Tie for Wire Bundles

With increasing use of electrical and electronic components and subsystems, properly securing cabling is an important—though often overlooked—aspect of system design.

Use IO-Link for Increased Flexibility, Availability, and Efficiency in Industry 4.0 Factories

Supporting the data gathering and analysis that are the hallmarks of Industry 4.0 can frequently require line and process changes that include adding, removing, or reprogramming digital sensors, actuators, indicators, and other devices.

Water Scarcity Problems Solved with Advanced Agricultural Irrigation

Over the last decade, many growers have replaced traditional irrigation timers and hydraulic regulators with advanced control and connectivity components adapted from those for industrial applications.

Related Videos

SEASON 4 IS POWERED BY

The modern factory is defined by technology that enables more efficient production and deeper insights into the critical data of day-to-day operations. In this season of Factory Tomorrow, we'll uncover how breakthroughs from industry leaders like Siemens and Banner Engineering, are driving efficiency, providing deeper insights into daily operations, and shaping the future of global production.

S4: EPISODE 1

Manufacturing the Digital Thread

In this episode, we explore how innovators like Siemens are enabling digital transformations in the manufacturing world. AI and machine learning are used to create digital representations of complex manufacturing systems. Find out how real-time simulation, data analysis, and predictive maintenance are creating the factories of tomorrow.

S4: EPISODE 2

Breaking Through with Industrial IoT

Industrial IoT (IIoT) focuses on machine-to-machine communication, allowing for user-friendly automation, higher efficiency, and longer asset longevity. In this episode, we explore how Banner Engineering is leading the charge with plug-and-play solutions for sensing, wireless connectivity, and machine safety.

S4: EPISODE 3

The Future of the Factory Floor

From simulation to safety, we learn how DigiKey, Siemens and Banner Engineering view breakthroughs in technology as a way to fill the gaps across the factory floor. The next generation of intelligent manufacturing will be shaped by artificial intelligence, real-time data, and enhanced human-computer interaction.

Related Products

Siemens

SINAMICS V20 Drives

Siemens' drives' compact, robust, and rugged design makes them ideal for a variety of applications.

Banner Engineering

Monitoring Solutions

These products are a low-cost, low-risk way to get started with condition monitoring providing a quick return on investment.

Siemens

SIMATIC ET 200 I/O Platform

Siemens I/O platform offers simple and flexible use of different fieldbus systems.

Banner Engineering

Remote I/O Solutions

Optimize machine control systems with remote I/O solutions from Banner Engineering.

Siemens

SIRIUS Modular

Sirius Innovations offers you a comprehensive portfolio of Industrial Controls.

Banner Engineering

S4B Series Heavy-Duty Type 4 Safety Light Curtains

Banner Engineering's safety light curtains install quickly and easily with LED zone alignment indicators.

Siemens

Reliable Power and Network Solutions

An efficient power supply and ethernet switch are requirements for operating any plant, no matter the industry or need.

Siemens

SIMATIC S7-1200 Basic Controllers

Siemens SIMATIC S7-1200 basic controllers are used in compact automation solutions with integrated communication and technology functions

Banner Engineering

T30R Series Radar Sensors

Banner Engineering's radar sensors detect a wide range of objects.

Siemens

Controls SIRIUS Contactors

Siemens SIRIUS 3RT20152AP611AA0 is a 3-phase standard power, 220/240 VAC coil, 7 A, 3NO contact, 3-pole contactor.

Banner Engineering

K50U Series Wireless Ultrasonic Sensors

Banner Engineering's K50U series wireless ultrasonic sensors make condition monitoring easy.

Siemens

SITOP SEL1200/SEL1400 Selectivity Modules

Siemens SEL1200 and SEL1400 power reliability selectivity modules offer efficient protection for users' plants.

Banner Engineering

Sure Cross® Temperature and Humidity Sensors

Banner Engineering's Sure Cross temperature and humidity sensor variants provide monitoring for environmental conditions.

Additional Content

Programming PLCs: A Technical Summary with Siemens Examples

Programmable logic controllers (PLCs) are ruggedized microprocessor-based electronics essential to all modern automation.

Integrated, High Performance, Networked Power Supplies for Factory Automation

Factory automation increases productivity and reduces costs through the application of technology and advanced control systems to a manufacturing process.

The Digital Twin Concept and How It Works

Implementing the Digital Twin culture, which includes real-world and virtual product-life-cycle management software, significantly reduces design cycle time, testing, and improves yields.

Remote I/O Devices Optimize Automation Control Systems

Factory and industrial automation systems must reliably connect human operators, machinery, computers, and sensors over communications links.

Eliminate Conveyor Jam False Alarms to Boost Factory Automation Productivity

This article briefly describes the two types of light sensors used for jam detection: LED and lasers.

How to Design a Modular Overlay Network for Industry 4.0 Data Processing Optimization in the IIoT

This article briefly discusses the problems of connecting legacy equipment to the IIoT.

Related Videos

SEASON 5 IS POWERED BY

This season peels back the layers of the robotic manufacturing cell to reveal the tech, infrastructure, and innovation that power modern automation. It's not just about the robot—it's about everything that makes the future of robotics possible.

S5: EPISODE 1

Inside the Robotic Cell

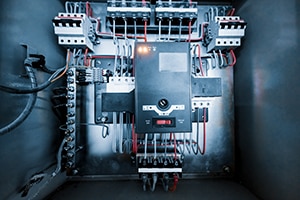

Every robot relies on a complex system working behind the scenes. In this episode, we crack open the robotic cell and explore its nervous system—from power distribution and motor control to circuit protection and control cabinets. Learn how Eaton's technology is playing a starring role in building smarter, safer automation infrastructure.

S5: EPISODE 2

Sensing the Shift: Safety Meets Precision

Robots may do the heavy lifting, but sensors do the thinking. We dive into the advanced sensing and safety technologies from SICK that help robots "see," "feel," and react in real time. From laser scanners to safety relays, this is the tech that keeps factories smart and people protected.

S5: EPISODE 3

Rebuilding the Line: Automation and the Workforce Revolution

Manufacturing is evolving fast. With reshoring on the rise and skilled labor in short supply, automation has become mission-critical. This episode explores how integrated systems—powered by companies like Eaton and SICK—are creating flexible, resilient production lines that meet the demands of today's industrial challenges.

Related Products

M22 Series 22 mm Pushbuttons

Eaton 22 mm pushbuttons provide endless opportunity for flexibility and reduced inventory with this versatile offering.

W12 Metal Photoelectric Sensors

SICK W12 metal photoelectric sensors are industrial-grade photo eyes with three detection types for any environment.

UL489 Industrial Miniature CBs

Eaton miniature circuit breakers (CBs) are available up to 480 VAC and available as a 1-, 2-, 3-, and 4- pole.

sensingCam SEC100 Industrial Camera

The SICK sensingCam SEC100 industrial streaming camera is ideal for process monitoring, documentation, and error analysis.

50 Series Photoelectric Sensors

Eaton photoelectric sensors are designed with many options, including fiber optic sensing.

microScan Safety Laser Scanner

The SICK microScan safety laser scanner is versatile and built to withstand tough conditions.

STR1 Series Non-Contact Safety Switches

SICK STR1 series safety switches offer maximum mounting flexibility no matter the space available on production lines or in applications.

Flexi Soft Safety Controller

The SICK software-programmable safety controller makes programming intuitive, commissioning nimble, and diagnostics seamless.

Additional Content

Behind the Robot: Sensing, Safety, and Control in Industry 4.0

This article explores the foundational technologies behind Industry 4.0 robotics, and how sensor solutions from SICK and industrial control components from Eaton contribute to safe motion control and deterministic decision-making.

Webinar – Essential Guide to Choosing Sensors and Safety

This webinar clarifies the understanding of safety requirements for sensors and how to implement them effectively.

Use Advanced Photoelectric Devices to Simplify the Deployment of Proximity Sensing

This article provides a brief overview of PE basics. It then introduces PE proximity sensors from SICK, Inc. and shows how they can be applied using a uniquely simplified setup process.

How to Select and Integrate Multi-Dimensional Safety Systems to Protect Workers from Cobots

Safety is essential when deploying collaborative robots (cobots), autonomous mobile robots (AMRs), and autonomous guided vehicles (AGVs) in factories and logistics facilities. It's also complex and multi-dimensional.