How to Ensure Safe and Efficient Modular BESS Deployments Using Pluggable Battery Pole Connectors

Contributed By DigiKey's North American Editors

2021-12-08

The use of modular battery energy storage systems (BESSs) is growing in residential, industrial, and utility-scale installations. Comprising multiple interconnected battery modules, BESSs provide backup power if the main grid fails, regulate peak energy usage in industrial settings, and support the grid integration of renewable energy sources such as wind and solar. While their modular architecture simplifies installation, enables scalability, and supports the efficient replacement of worn-out battery modules, designers need to be particularly careful about their choice of battery pole connectors.

Along with meeting the latest safety and performance standards, as well as being rugged and cost-effective, designers need to factor in connector flexibility for orientation and the ability to withstand multiple insertion/withdrawal cycles, while maintaining minimal electrical contact resistance to prevent overheating. Also, to ensure user safety, features like polarity reversal protection and being fully touch-proof should be on the checklist of requirements.

This article discusses the issues associated with BESS module connectivity. It then introduces and shows how to apply a line of pluggable battery pole connectors from Phoenix Contact that are designed for BESS applications.

Performance requirements for battery pole connectors

The performance expectations for battery pole connectors vary between residential, commercial, and utility applications (Table 1). While safety is a priority for all, residential installations benefit from high levels of flexibility. Maintenance considerations are important in commercial BESS designs. Utility-scale BESS installations place less emphasis on flexibility but are the most demanding application overall, with the expectation of fast installation (low labor time), high safety, low failure rates, low cost, and efficient maintenance. Selection of the right connectivity solution is critical to meet the varying performance demands.

|

Table 1: Different applications have varying requirements for BESS connector performance. The right battery pole connector can meet the demands of all three application categories. (Image source: Phoenix Contact)

Cable lug wiring assemblies are a common method for connecting the battery modules in a BESS (Figure 1). Lug connectors are relatively inexpensive, but they have several disadvantages when used in a BESS installation:

- They suffer from poor standardization and lack application flexibility

- Manually connecting and tightening the nuts on each lug connector is a time-consuming process and can be prone to wiring errors

- If the nuts are not properly tightened, the connection can have a high resistance, resulting in overheating

- Lug connectors are not protected from the environment; when used in outdoor enclosures the reliability of lug connectors can be reduced by exposure to dust or low-pressure water jets as well as condensation and water spray

- Lug connectors are not touch-safe and do not comply with current safety standards, presenting a potential shock hazard to installers and maintenance personnel

Figure 1: Wiring a modular BESS with cable lug assemblies is time-consuming and prone to wiring errors, and lug connectors are not inherently touch-safe. (Image: Phoenix Contact)

Figure 1: Wiring a modular BESS with cable lug assemblies is time-consuming and prone to wiring errors, and lug connectors are not inherently touch-safe. (Image: Phoenix Contact)

To overcome the drawbacks of using lug connectors, designers can turn to specially designed pluggable battery pole connectors from Phoenix Contact that meet the requirements of consumer, commercial/industrial and utility BESS installations (Figure 2).

Figure 2: Pluggable battery pole connectors for BESS overcome the limitations of lug connectors and meet the performance demands of consumer, industrial and utility installations. (Image source: Phoenix Contact)

Figure 2: Pluggable battery pole connectors for BESS overcome the limitations of lug connectors and meet the performance demands of consumer, industrial and utility installations. (Image source: Phoenix Contact)

These connectors offer good accessibility and the flexibility to connect to the battery pole from any direction for quick installation, with low contact resistance. They include polarity-reversal protection and are fully touch-proof for operator safety. An IP65 rated housing provides protection from dust ingress and against low-pressure water jets from any direction, plus protection from condensation and water spray.

The connectors have an International Electrotechnical Commission (IEC) overvoltage category III rating and are capable of withstanding transient voltages in fixed installations such as outdoor cabinets that house BESSs. They have an IEC 60664-1 degree of pollution rating of 2, making them suitable for use in environments where only non-conductive pollution occurs, except that occasionally a temporary conductivity condition caused by condensation may occur.

The Phoenix Contact pluggable battery pole connectors are color-coded and mechanically keyed to prevent cross-wiring and can be simply plugged into the touch-protected socket where they click into place and lock into position (Figure 3).

Figure 3: These pluggable battery pole connectors are mechanically keyed and color-coded to prevent cross-wiring. A “click” is heard when they plug into the touch-protected socket and lock into position. (Image source: Phoenix Contact)

Figure 3: These pluggable battery pole connectors are mechanically keyed and color-coded to prevent cross-wiring. A “click” is heard when they plug into the touch-protected socket and lock into position. (Image source: Phoenix Contact)

Further simplifying and speeding installation, the connectors can be rotated up to 360˚ as needed. The use of these battery pole connectors can save three-quarters of the typical installation time needed when compared to using lug connectors. A typical industrial or commercial battery rack can have 10 to 12 modules, while a utility-scale BESS installation in a container has hundreds or thousands of battery modules. In such applications, the installation time and cost savings from using specially designed battery pole connectors compared with lug connectors is substantial.

These pluggable battery pole connectors feature low contact resistance and support high levels of reliable and safe operation, including positive locking mechanisms to prevent accidental disconnects (Figure 4). They are rated at 1500 volts DC (VDC), 120 amperes (A), and for over 100 insertion/withdrawal cycles with an insertion force ≤ 75 Newtons (N) and a withdrawal force of ≥10 N.

Figure 4: These pluggable battery pole connectors have a positive locking mechanism: On the left (A) the locking mechanism/release lever is shown in its locked state; the middle (C) shows the pair disconnected; this disconnection is achieved by sliding the locking mechanism (right, B) forward towards the mating interface. (Image source: Phoenix Contact)

Figure 4: These pluggable battery pole connectors have a positive locking mechanism: On the left (A) the locking mechanism/release lever is shown in its locked state; the middle (C) shows the pair disconnected; this disconnection is achieved by sliding the locking mechanism (right, B) forward towards the mating interface. (Image source: Phoenix Contact)

Battery pole connector examples

The battery pole connector system from Phoenix Contact consists of pairs of cable connectors and panel-mount connectors with silver-plated contacts, having a total contact resistance of ≤5 milliohms (mΩ). The connectors are rated according to UL 4128, the latest UL standard for battery applications. Prior to this standard, most battery connectors were rated using the UL 1977 standard, which is a more generalized standard with a maximum voltage rating of 1,000 VDC. The Phoenix Contact battery pole connectors are rated to 1500 VDC , meeting the UL 4128 standard. In addition to meeting the latest UL 4128 standard (listed below), these battery pole connectors satisfy the requirements of important BESS related international standards, including:

- IEC 61984 – Connectors - Safety requirements and tests

- IEC 62933 – Electrical energy storage (EES) systems

- IEC 63066 – Low-voltage docking connectors for removable energy storage units

- UL 9540 – Standard for Energy Storage Systems and Equipment

- UL 4128 – Outline of Investigation for Intercell and Intertier Connectors for Use in Electrochemical Battery System Applications

Cable connectors such as the 1106307 come in black for negative poles, while the 1106306 connector comes in orange for positive poles (Figure 5). A crimp termination on the cable connectors can handle 16 square millimeter (mm²) and 25 mm² cable sizes, with a stripping length of 22 mm. A sliding locking mechanism prevents accidental disconnections.

Figure 5: The cable connector half of the battery pole connector system is offered in orange for positive poles (pictured above) and black for negative poles. It includes a sliding locking mechanism (on the right-hand side of the connector above) to prevent accidental disconnections. (Image source: Phoenix Contact)

Figure 5: The cable connector half of the battery pole connector system is offered in orange for positive poles (pictured above) and black for negative poles. It includes a sliding locking mechanism (on the right-hand side of the connector above) to prevent accidental disconnections. (Image source: Phoenix Contact)

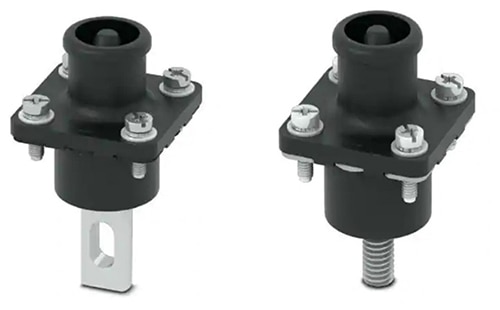

In addition to fulfilling the technical requirements of installers and system integrators, the panel-mount battery pole connectors offer BESS system designers the flexibility of choosing a busbar or screw post attachment within the system (Figure 6). Like the cable connectors, the panel-mount connectors are offered in orange for positive poles (with a choice of busbar, such as 1130816, or screw post attachments, like 1106303) and black for negative poles (with a choice of busbar, for example 1130814, or screw post attachments, such as 1106304).

Figure 6: The panel-mount battery pole connector half is available with busbar (left) or screw post (right) system connection options. (Image source: Phoenix Contact)

Figure 6: The panel-mount battery pole connector half is available with busbar (left) or screw post (right) system connection options. (Image source: Phoenix Contact)

A summary of performance features and benefits of the battery pole connector system includes:

- 75% faster installation time compared with lug connectors, reduces cost of installation

- Color-coded for polarity identification:

- Orange (+) positive

- Black (-) negative

- Black and orange connector pairs have unique interfaces to prevent cross-mating

- Positive locking mechanism prevents accidental disconnections

- Cable connectors have crimp terminations for 16 mm² and 25 mm² wire sizes

- The mated connector system can be rotated 360° to simplify installation

- Rated for 100 insertion/withdrawal cycles with an insertion force ≤75 N and a withdrawal force of ≥10 N

- Fully touch-proof design for operator safety

- IP65 rated housings provide environmental protection

- Silver-plated contacts for a contact resistance ≤5 mΩ and reliable connection interface

- IEC rated for 120 A and 1500 VDC

- Operating temperature range of -40°C to +125°C

Design and application considerations

To ensure safe and reliable operation, there are several factors that designers and installers need to take into consideration when using pluggable battery pole connector systems:

- Do not connect or disconnect the connectors under load.

- The connector must be fully plugged in and interlocked before it is energized.

- Under normal operation, the connector will be warm. Under high-temperature ambient conditions, these connectors can continue to get warmer. If the connector is expected to be used in high ambient temperature conditions, burn warnings such as those required by DIN EN ISO 13732-1:2008-12 may be needed.

- A protective cap should be placed on connectors that are not being used.

- The tensile load on the connectors in a cable assembly cannot exceed the upper limit of the specification.

Conclusion

As the deployment of BESS systems accelerates to ensure reliable power and adapt to renewable energy sources, designers need to pay extra attention to the requirements for the battery pole connectors for these modular battery systems. Using pluggable battery pole connectors, designers can meet core safety and performance requirements, while also supporting the reliability, scalability, maintenance, environmental, and cost requirements of residential, commercial/industrial, and utility BESS installations.

Recommended Reading

Disclaimer: The opinions, beliefs, and viewpoints expressed by the various authors and/or forum participants on this website do not necessarily reflect the opinions, beliefs, and viewpoints of DigiKey or official policies of DigiKey.