Integrated, High Performance, Networked Power Supplies for Factory Automation

The goal of factory automation is to increase productivity and reduce manufacturing costs through the application of technology and advanced control systems to a manufacturing process. For this, it relies upon computer-controlled workstations to handle material and workflow, with human operators needed only for supervision, monitoring, adjustment, and maintenance. While many technologies converge to make this possible, at its foundation are reliable, efficient, and integrated power supplies that have been designed and manufactured with the needs of factory automation in mind.

For example, the SITOP line of power supplies from Siemens offers a range of basic, standard, and advanced options. Over the years, their advanced power supply line has emerged to become the top choice for maximum reliability and automated functionality, including efficiency, compactness, overload behavior, and system integration. Siemens SITOP standard-class power supplies are designed for less-stringent industrial applications that still require ruggedness and comprehensive diagnostics.

Let’s look at these two SITOP options more closely.

Advanced, fully integrated power supplies

The Siemens SITOP power system advanced class power supplies include the 6EP34378MB002CY0, which is part of the company’s PSU8600 power supply series. The 6EP34378MB002CY0 is a four-output, 24 volt (nominal) power supply that mounts on a DIN rail. The output voltage levels are adjustable from 4 to 28 volts. Each output can supply up to 10 amperes (A) for a total output power rating of 960 watts. Outputs 1 and 2, or 3 and 4, can be tied together in parallel to obtain 24 volts at 20 A on two outputs. The input is three-phase AC between 400 and 500 volts. Other versions of the PSU8600 are available with single or two-phase inputs.

The overall efficiency of the 6EP34378MB002CY0 is 93%, which helps keep it operating coolly. This allows the power supply to be passively cooled via natural convection. Its metal housing requires no clearance on either side and only 50 millimeters (mm) (1.97 inches (in.)) clearance, top and bottom. It is rated to operate over a temperature range of -40 to +60°C.

The 6EP34378MB002CY0 is a compact system, measuring just 125 mm (4.92 in.) wide, 125 mm (4.92 in.) high, and 150 mm (5.9 in.) deep. The physical dimensions of the basic unit complement the other PSU8600 supplementary modules, including power supply expansion, buffer, uninterruptable power supplies (UPS), and battery modules (Figure 1).

Figure 1: Shown is a Siemens SITOP PSU8600 base power supply with expansion and supplementary modules. The inset shows the system clip link, which connects the modules electrically. (Image source: Siemens)

Figure 1: Shown is a Siemens SITOP PSU8600 base power supply with expansion and supplementary modules. The inset shows the system clip link, which connects the modules electrically. (Image source: Siemens)

You can augment the PSU8600 base unit power supply by using the unique system clip link to add additional modules. Expansion power supply modules add additional power outputs, up to 36 in total.

Short-term power failures can be bridged using buffer modules for periods of 100 milliseconds (ms) to 10 seconds (s), which should be sufficient time to shut down processes safely. UPS and battery modules provide backup power for longer periods, in the order of hours.

All the expansion modules electrically connect modules to the base unit via the system clip link, which handles both power and data transfer, minimizing the need for additional wiring.

The PSU8600 power supplies can be fully integrated into automation systems and the Total Integrated Automation (TIA) portal (Figure 2).

Figure 2 : The PSU8600 components offer comprehensive data exchange and integration. (Image source: Siemens)

Figure 2 : The PSU8600 components offer comprehensive data exchange and integration. (Image source: Siemens)

The PSU8600 base unit includes dual PROFINET ports. PROFINET stands for Process Field Network and is an automation industry data communication standard using Industrial Ethernet. It is designed for data collection and control of equipment in industrial systems.

The base unit also includes OPC-UA, which stands for Open Platform Communications Unified Architecture. It is a cross-platform, open-source standard for data exchange from sensors to cloud applications developed by the OPC Foundation. In essence, it is a machine-to-machine communication protocol used for industrial automation.

The power supply supports Siemens’ SIMATIC WinCC, a human-machine interface (HMI) system. Siemens supplies a SITOP library, which provides the user with modules and faceplates for direct integration into SIMATIC PCS 7. It also offers SITOP Manager, a tool for initial configuration (commissioning), engineering, and monitoring of SITOP power supplies that is independent of engineering frameworks like SIMATIC TIA Portal or SIMATIC PCS 7.

Any of these systems can monitor and control the PSU8600. The output voltages can be set or changed, and complete operating status and diagnostics information like output currents, voltages, and overload or short-circuit conditions can be monitored.

Standard power supplies

Standard-class power supplies are compact, rugged, energy-efficient, and are fast and easy to install. They are intended for a wide range of fixed-voltage industrial applications that do not require the same high degree of control as the advanced power supplies. Their system integration focus is on operational status and diagnostics.

The Siemens PSU6200 series power supplies, along with their add-on modules, are the backbone of the standard class power sources (Figure 3).

Figure 3: Shown are examples of PSU6200 power supplies that are available with AC or DC power sources and output current ranges from 1.3 to 40 A. (Image source: Siemens)

Figure 3: Shown are examples of PSU6200 power supplies that are available with AC or DC power sources and output current ranges from 1.3 to 40 A. (Image source: Siemens)

The PSU6200 series power supplies use a similar DIN rail enclosure, permitting side-by-side mounting and convection cooling. They are available with voltage outputs of 12, 24, or 48 volts, with output current ratings from 1.3 to 40 A. The specifications for some of the more commonly used PSU6200 power supplies are summarized in Table 1.

| Model | Input type | Input voltage (V) | Output power (Watts) | Output voltage (V) | Output current (A) | Efficiency (%) | Number of outputs |

| 6EP34447SB003AX0 | AC/DC | 323-576 450-600 |

240 | 48 | 5 | 95.6 | 1 |

| 6EP34467SB003AX0 | AC/DC |

323-576 450-600 |

480 | 48 | 10 | 96.2 | 1 |

| 6EP34477SB003AX0 | AC/DC |

323-576 450-600 |

960 | 48 | 20 | 96.6 | 1 |

| 6EP34367SC003AX0 | AC/DC |

323-576 450-600 |

480 | 24 | 20 | 95.9 | 1 |

| 6EP34377SB003AX0 | AC/DC |

323-576 450-600 |

960 | 24 | 40 | 96 | 1 |

| 6EP34377SC003AX0 | AC/DC |

323-576 450-600 |

960 | 24 | 40 | 95.9 | 1 |

The availability of multiple supplies with a common voltage and different output current ratings makes upgrading to a higher power level very easy. Note also that the source voltages for these power supplies can be AC or DC single phase; other power supplies in the series use three-phase AC.

All the PSU6200 series supplies have excellent efficiency of 95% or better, thereby reducing heat and improving reliability.

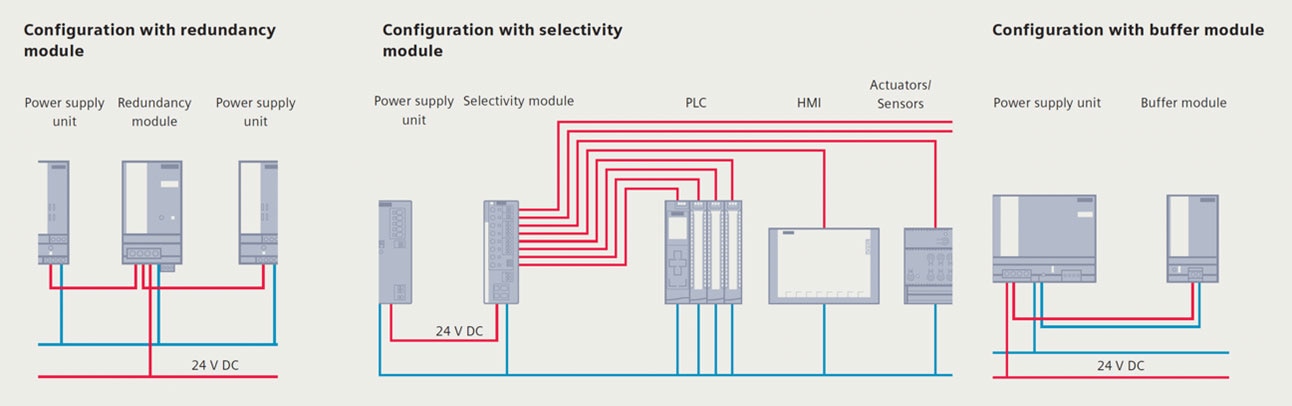

The basic power supply unit can be augmented by add-on modules, including expansion, redundancy, selectivity, buffer, and UPS modules (Figure 4).

Figure 4 : Add-on modules improve the reliability and stability of the power bus in the presence of unstable power sources and loads. (Image source: Siemens)

Figure 4 : Add-on modules improve the reliability and stability of the power bus in the presence of unstable power sources and loads. (Image source: Siemens)

Expansion, buffer, and UPS modules were discussed previously and perform the same function within the standard class power supplies. The redundancy modules connect two power supplies together so that if one unit fails, the other takes over supplying the load, preventing downtime. The selectivity module monitors individual bus line currents, and in the event of a short circuit or a load that is higher than expected, it shuts down the faulty circuits to prevent the loss of the entire bus.

The power supply units in the table, with maximum power output levels of 240 watts or greater, are equipped with active power factor correction (PFC). Additionally, they include a built-in diagnostics LED display and a diagnostic interface port for connection to the automation software.

The diagnostic display monitor conveys key operating parameters and status, including voltage OK, current utilization, and service life status. The diagnostic interface is a serial data bus that interfaces to a digital input of a programmable logic controller (PLC) or other automation software. The diagnostics port provides output voltage, load current status, operating hours, and temperature status, as well as the device type (Figure 5).

Figure 5 : The diagnostic monitor display (left) and the WinCC PSU6200 series faceplate (right) show the power supply status. (Image source: Siemens)

Figure 5 : The diagnostic monitor display (left) and the WinCC PSU6200 series faceplate (right) show the power supply status. (Image source: Siemens)

Conclusion

Whatever the power needs in your automated factory, the Siemens SITOP power supplies and auxiliary add-ins are there to support critical production processes. The complete and coordinated range of power products, in conjunction with easy-to-use software, guarantees a reliable power system that is readily integrated into the modern factory.

Have questions or comments? Continue the conversation on TechForum, DigiKey's online community and technical resource.

Visit TechForum