Use Advanced Photoelectric Devices to Simplify the Deployment of Proximity Sensing

Contributed By DigiKey's North American Editors

2024-11-07

Photoelectric (PE) sensors are widely used for non-contact proximity sensing in production, industrial, and commercial systems due to their effectiveness, robustness, and clarity of operating principles. Typical applications include the detection of bottles or cans on a high-speed production line, looking for the absence or presence of a package in a shipping box, checking for an open or closed door, or human presence detection.

PE proximity sensors can be designed for different optical-sensing modes, and the basic retro-reflective approach is a typical arrangement. Despite the simple operating principle, setting up a PE sensor can require time-consuming trial and error to initialize, fine-tune, and optimize the configuration and sensing algorithm to the application's specifics, or re-adjust it for a different production run. System designers need a more streamlined solution to avoid the associated setup and delayed deployments.

This article provides a brief overview of PE basics. It then introduces PE proximity sensors from SICK, Inc. and shows how they can be applied using a uniquely simplified setup process.

PE sensing basics

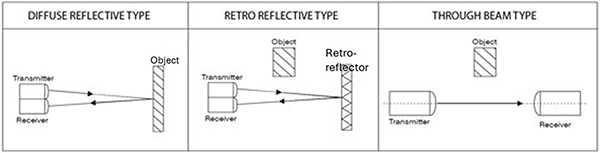

PE proximity sensing relies on a light source with a tightly focused beam directed toward the object to be detected. This light beam is then used in one of three ways depending on how it is detected by a receiver (Figure 1).

Figure 1: PE proximity sensing can use a transmitted light beam and corresponding photosensitive receiver in three physical arrangements. (Image source: Proximity Switch)

Figure 1: PE proximity sensing can use a transmitted light beam and corresponding photosensitive receiver in three physical arrangements. (Image source: Proximity Switch)

- In diffuse-reflective sensing, the transmitter and receiver are housed together, and detection occurs when the light beam from the transmitter bounces off the object of interest.

- In retroreflective sensing, the transmitter and receiver are also in the same housing but with the reflector on the far side of the target object.

- In through-beam sensing, the photosensor is situated on the other side of the object, and the object indicates its presence by blocking the light from the transmitter to the receiver.

PE proximity sensing can also be used for safety purposes, such as light barriers or light curtains, where these devices are mounted strategically and serve as safety gates (Figure 2). When an obstruction is detected, the light barrier will send a signal to a controller or hardwired safety circuit that will shut down the machine if the obstruction is unexpected or hazardous.

Figure 2: Proximity sensing can be used in a safety-related light barrier or curtain. (Image source: SICK, Inc.)

Figure 2: Proximity sensing can be used in a safety-related light barrier or curtain. (Image source: SICK, Inc.)

PE sensing is attractive since it uses an intuitive operating principle and physical arrangement. The reflective approaches are also desirable as they require a wired device on only one side, simplifying installation logistics.

A new design and user interface resolves many challenges

Despite its conceptual simplicity, PE proximity sensing requires careful field mounting, installation, and alignment. Visually noisy environments can be challenging and frustrating for technicians, and range and aim considerations affect performance and consistency.

PE sensing is frequently used with a programmable logic controller (PLC). Often, the installer must set up, test, adjust, and retest at the PLC, which may be some distance from the PE unit. Further, variations in lighting, unwanted and changing reflections, and other real-world distortions may affect the performance and accuracy.

Problems that crop up during production runs are especially vexing and are often aggravated by the urgency to fix them quickly.

To overcome these issues, SICK developed the W10 family of proximity sensors (Figure 3).

Figure 3: The W10 series provides complete, sophisticated PE proximity sensors in a compact, rugged housing. (Image source: SICK, Inc.)

Figure 3: The W10 series provides complete, sophisticated PE proximity sensors in a compact, rugged housing. (Image source: SICK, Inc.)

The units are especially noteworthy for being the first such devices with a touchscreen display (Figure 4).

Figure 4: The unique integrated touchscreen of the W10 units provides a greatly enhanced user experience. (Image source: SICK, Inc.)

Figure 4: The unique integrated touchscreen of the W10 units provides a greatly enhanced user experience. (Image source: SICK, Inc.)

This display interface offers ease of use, supports quick installation, and accelerates adaption to each application. Its easy navigation reduces the time it takes to get the device up and running and facilitates in-use adjustments for different targets, speeds, or unexpected problems. It also eliminates the need for physical switches, knobs, and adjustments on the unit, thus enhancing reliability, enclosure integrity, and security.

The W10 series’ Class 1 laser light source delivers accurate detection results with high repeat accuracy. The focused red laser beam produces a small light spot on an object and is combined with a fast and precise receiver laser-triangulation system and evaluation line scanning.

This is the foundation for detection results with high repeat accuracy and rapid decisions. In speed mode, the response time is just 1.8 milliseconds (ms), so reliable switching behavior is guaranteed even at high machine speeds. Two-color indicator LEDs provide immediate visual feedback on the detection status. Further, the units offer robust and reliable detection of objects with different surface properties such as gloss, color, or structure.

The PE proximity sensors offer individual “teach-in” (learning) options for specific adaptations. In addition to the usual one-point teach, which detects objects at a defined distance, a two-point teach mode enables the detection of objects of different heights. A manual mode extends the teach options and offers even more flexibility. Three application-optimized operating modes can be activated using the display to enable foreground or background suppression if required.

From the integral touch screen, the operator can intuitively select, adjust, and save settings for speed, standard or precision operating modes, ambient suppression, individual teach-in settings, preconfigured parameters, and limit values. The unique security-screen lock feature of the W10 protects the settings against third party access.

User interface flexibility is not restricted to the touchscreen: the same functions can be accessed via the W10 IO-Link function. This provides the option of remote configuration and efficient integration of the recorded sensor data into an existing automation network.

Electrical options and packaging for the W10

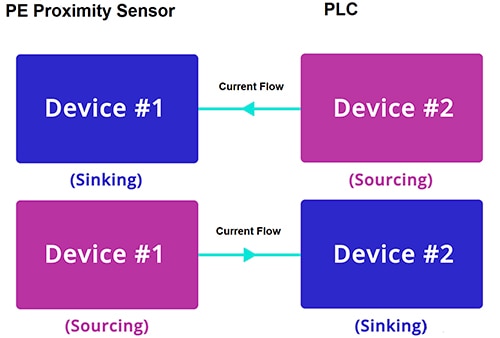

The digital output of the W10 sensor devices is an important design consideration. The units offer an adjustable push/pull PNP/NPN output structure. If the output is set to PNP, it has a positive output signal, and the sensor’s output can source current for a current-sinking input card; if the sensor is set to NPN, the output signal is negative, and the output can sink current for connection to a current-sourcing input card (Figure 5). Having both options ensures basic signal-level compatibility with a PLC or other system controllers.

Figure 5: The output stage of the W10 units can provide both current-sink (top) or current-source modes (bottom) to guarantee compatibility with the associated PLC. (Image source: www.realpars.com)

Figure 5: The output stage of the W10 units can provide both current-sink (top) or current-source modes (bottom) to guarantee compatibility with the associated PLC. (Image source: www.realpars.com)

The output can be configured for light or dark output modes (light-on or dark-on). In light mode, the sensor’s output will be on when the light can reach the receiver and off when the light is blocked. In contrast, in dark mode, the sensor’s output will be on when the light is blocked and off when the light reaches the receiver.

Physical packaging is important since these units are typically used in industrial settings. The W10 units have a sturdy design with a 316L stainless steel housing and IP67 and IP69k protection ratings. They are offered in an 18 × 57 × 42.2 millimeter (mm) package and are specified for operation over the ambient temperature range of -10°C to +55°C.

One of the challenges with industrial sensors is the need to support various units in the field or factory. This reality complicates in-house inventory and support. However, due to the flexibility of the W10 series, the family requires just two body styles (Figure 6). Each of these has two sensing ranges for a total of just four distinct models, simplifying the selection process.

Figure 6: The functionally similar units in the W10 family are available in two housing styles, each with two sensing ranges. (Image source: (SICK, Inc.)

Figure 6: The functionally similar units in the W10 family are available in two housing styles, each with two sensing ranges. (Image source: (SICK, Inc.)

The W10 series model 1133545 is available in a rectangular housing with an object distance of 25 mm to 400 mm, while the similar model 1133547 supports an object distance of 25 mm to 700 mm. For hybrid installations, model 1133544 features a threaded, front-or-side M18 mounting connector with an object distance of 25 mm to 400 mm, and the corresponding W10 model 1133546 has the same enclosure but with an object distance of 25 mm to 700 mm.

Conclusion

The W10 PE sensor units provide versatile, rugged diffuse reflector solutions for industrial applications. Their advanced features include the industry’s first integral touchscreen user interface, simplifying installation, setup, and adjustment, while their sophisticated algorithms provide enhanced capabilities and accuracy.

Disclaimer: The opinions, beliefs, and viewpoints expressed by the various authors and/or forum participants on this website do not necessarily reflect the opinions, beliefs, and viewpoints of DigiKey or official policies of DigiKey.