How to Select and Apply the Right Cable Tie for Wire Bundles

Contributed By DigiKey's North American Editors

2022-10-07

With increasing use of electrical and electronic components and subsystems, properly securing cabling is an important—though often overlooked—aspect of system design. Whether it be within a device or between systems, ensuring that cables are routed securely, safely, and efficiently is critical to design success and longevity, particularly in high-vibration and environmentally harsh applications.

For designers, the challenge is to find cable ties that will meet the needs of the application with respect to tensile strength, longevity, flexibility, chemicals, vibration, and ultra-violet (UV) radiation tolerance, without over-designing or compromising the integrity of the cable’s insulation and internal structure.

This requires an analysis of the multiple types of cable ties and the variety of materials that are now available and differentiating between them with the concern that choosing the wrong cable tie can end up costing much more than what is spent on their purchase.

To alleviate these concerns, designers need to understand the nuances of cable ties and how to align their choice with the application requirements. This article will provide an overview of cable tie considerations, the advantages of each type, and how to apply them effectively using real-world examples from Panduit Corporation.

Cable tie specifications

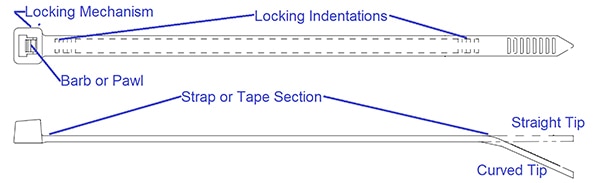

Cable ties, often called zip-ties or tie wraps, are available in many lengths, widths, materials, and colors. When tying a wire bundle, the tie strap or tape section should fit around the bundle, with the loose end pulled completely through the locking mechanism and tightened until the strap locking indentations firmly engage (Figure 1).

Figure 1: A typical cable tie showing the main parts used to secure cable bundles. (Image source: Panduit Corporation)

Figure 1: A typical cable tie showing the main parts used to secure cable bundles. (Image source: Panduit Corporation)

Cable ties can be constructed as a single piece where the locking barb is molded as part of the locking mechanism. In contrast, a higher-quality tie uses two-piece construction. In the two-piece design, a corrosion-resistant stainless-steel barb is embedded into the locking head to grip a relatively smooth tie surface. It is designed to provide a firm lock that is infinitely adjustable as the barb does not need to fit into a locking indentation.

The maximum diameter specification indicates the largest diameter wire bundle that the tie accommodates. The bundle should be held firmly without overtightening and cutting or abrading the cable insulation. The tie length used should account for a little extra to engage the loose end in the locking mechanism.

The strength of the wrap is defined as the loop tensile strength (LTS) measured in pounds. The LTS is the maximum amount of force that can be applied to the locking mechanism once it has been engaged. The most common ties range between 18 lb and 250 lb.

The LTS is dependent on the dimensions of the tie as well as the material used. Material selection is mostly influenced by the environmental operating conditions that the cable tie will experience. Considerations include:

- Is it intended for interior or exterior use?

- What is the expected temperature range?

- Will it be exposed to water, oil, chemicals, or vibration?

As an example, Panduit’s PLT1.5M-M10 cable tie is part of the company’s PAN-TY@PLT series of ties. This family of cable ties is its largest and most comprehensive product offering with ties of many colors, materials, and construction types. The PLT1.M-M10 has a nominal length of 5.6 inches (in.), a rated maximum diameter of 1.25 in., and a tensile strength of 18 lb. Tie straps are graded by their cross sectional area into sub-miniature, miniature, or intermediate. The PLT1.M-M10 is a miniature tie and is designed with one-piece construction. It is fabricated with nylon 6.6 and is intended for indoor use.

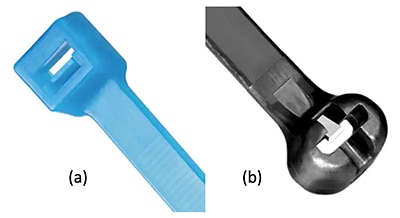

As mentioned previously, another common cable tie design comprises two pieces with a separate stainless-steel barb replacing the molded nylon barb in the single-piece design (Figure 2).

Figure 2: A single-piece fabrication with a molded locking barb (a) is shown alongside a dual-piece fabrication that uses a stainless-steel barb that is inserted after molding (b). (Image source: Panduit Corporation)

Figure 2: A single-piece fabrication with a molded locking barb (a) is shown alongside a dual-piece fabrication that uses a stainless-steel barb that is inserted after molding (b). (Image source: Panduit Corporation)

The aqua blue cable tie shown on the left in Figure 2, is Panduit’s PLT3S-C76—one of the variants of the PAN-TY@PLT series. It is made of ethylene tetrafluoroethylene (ETFE) and is intended for applications requiring chemical resistance, flame retardance, and radiation resistance. The cable tie on the right in Figure 2 is Panduit’s BT4S-M0, a member of the DOME-TOP BARB-TY BT series manufactured with a separate barb. Additionally, this series of ties features a rounded head and rounded edges on the strap to minimize abrasion of wire insulation. The black color, achieved by adding carbon black to the nylon, improves tolerance to ultraviolet light, making this color more commonly used in outdoor applications.

Cable ties are manufactured with a range of materials specific to their intended application environment. Basic ties are molded of nylon 6.6. Nylon 6.6 exhibits high mechanical strength, rigidity, good heat tolerance, and reasonable chemical resistance. Variants include weather resistant, heat stabilized, and flame-retardant nylon 6.6.

A variety of other materials are used to achieve specific tolerances. For example, the DT8EH-Q0 is designed for high strength, as well as resistance to impact, chemicals, ultraviolet light, and weather. It uses acetal (polyoxymethylene, or POM), a family of materials that includes Delrin. It measures 2.25 feet (ft.) long and has a tensile strength of 250 lb. These cable ties are designed for harsh outdoor applications in the power and communications industries.

Temperature range

The temperature range that a cable tie can withstand is determined primarily by the material used in its construction. Nylon 6.6 is rated to operate over a temperature range of -76°F to +185°F. Heat-stabilized Nylon 6.6 extends the upper end of the range to 212°F. PEEK has the highest temperature tolerance, with an upper-temperature limit of 500°F.

Special features

The Panduit CBR1M-M, part of the Contour-Ty series, has a unique design to prevent damage to wire insulation or cable jackets. It is designed with a low-profile head using parallel entry to limit the exposure of sharp edges and reduce snags, and has the locking indentations on the outside of the strap (Figure 3).

Figure 3: The Contour-Ty series uses a locking mechanism that is set at a right angle to the strap section for parallel insertion, as well as locking indentations on the outside to prevent insulation damage. (Image source: Panduit Corporation)

Figure 3: The Contour-Ty series uses a locking mechanism that is set at a right angle to the strap section for parallel insertion, as well as locking indentations on the outside to prevent insulation damage. (Image source: Panduit Corporation)

The HV9150-C0 inline cable tie uses weather-resistant Nylon 6.6. Mechanically, it uses a locking mechanism with a two-wedge design to allow both fixed and flexible locking (Figure 4).

Figure 4: The HV9150-C0 uses an inline design for parallel entry into the locking mechanism for a lower profile on cable bundles. (Image source: Panduit Corporation)

Figure 4: The HV9150-C0 uses an inline design for parallel entry into the locking mechanism for a lower profile on cable bundles. (Image source: Panduit Corporation)

The releasable head allows for temporary bundling prior to final locking. The indentations are molded into both sides of the strap, providing additional locking strength and greater flexibility. It has a length of 1.721 ft., a bundle diameter of 5.92 in., and a tensile strength of 160 lb.

The SST1.51-M cable tie is 5.3 in. long with a tensile strength of 40 lb (Figure 5). It is designed with a small head height for both normal bundling and through-panel applications. Its two-piece design has what Panduit claims is the industry’s lowest threading force, and it is 14% lighter than single-piece designs. In addition, the tie is releasable until final tensioning.

Figure 5: The SST1.51-M two-piece design uses a floating collar to lock the strap against a toothed wedge. Prior to final locking, the tie can be released by pulling the collar back and bending the wedge away from the strap. (Image source: Panduit Corporation)

Figure 5: The SST1.51-M two-piece design uses a floating collar to lock the strap against a toothed wedge. Prior to final locking, the tie can be released by pulling the collar back and bending the wedge away from the strap. (Image source: Panduit Corporation)

Where most cable ties have low stretch capability, the Panduit ERT2M-C20 has a body that is designed to be flexible (Figure 6).

Figure 6: The ERT2M-C20 elastomeric cable tie has a flexible strap to prevent over-tightening. (Image source: Panduit Corporation)

Figure 6: The ERT2M-C20 elastomeric cable tie has a flexible strap to prevent over-tightening. (Image source: Panduit Corporation)

This type of tie is designed to conform to a wire or optical cable bundle to prevent over-tightening. It also has a high coefficient of friction that grips wires to prevent lateral movement. This releasable tie is 8.5 in. long and has a tensile strength of 18 lb. Like other ties in the series, it is UL94V-0 flame resistance rated—meeting stringent telecommunication flammability requirements—and is halogen free and non-toxic.

The SG100M-M0 is intended for the rough installation practices of the maintenance, repair, and overhaul environment, as well as the construction industry (Figure 7).

Figure 7: The SGM100M-M0 ties feature a low installed head height, flared neck, and a tapered tip for easy threading. (Image source: Panduit Corporation)

Figure 7: The SGM100M-M0 ties feature a low installed head height, flared neck, and a tapered tip for easy threading. (Image source: Panduit Corporation)

Made with weather-resistant Nylon 6.6, it is ideal for applications subject to intense ultraviolet exposure. It is 4.2 in long and has a rated tensile strength of 18 lb. Its thin, wide strap is designed for flexibility to grip the cable bundle tightly and reduce lateral wire motion.

Conclusion

Although cable ties are often taken for granted, designers need to carefully consider the many available options to ensure the most appropriate tie is used for an application. As shown, cable ties are available in lengths from inches to multiple feet, are compatible over a wide range of environments, and come with many features to fit the needs of various applications.

Disclaimer: The opinions, beliefs, and viewpoints expressed by the various authors and/or forum participants on this website do not necessarily reflect the opinions, beliefs, and viewpoints of DigiKey or official policies of DigiKey.