How to Design Industrial Control Panels for Space, Efficiency, and Safety

Contributed By DigiKey's North American Editors

2023-08-31

Industrial control panel designers face a multitude of challenges. These include limited space and budget, environmental hazards such as loss of power and exposure to chemicals, and human factors such as misuse and tampering. Despite these difficulties, designers must produce a panel that provides uncompromising security, safety, reliability, and compliance with standards.

To achieve these goals, designers need creative solutions that simplify the creation, installation, and use of the control panel. Specifically, they need components that are tailor-made for their specific use case, as well as installation and maintenance tools that ensure proper operation.

This article provides guidance on selecting these components, with a focus on cost and space optimization. It covers wiring systems, identification systems, safety systems, access controls, and UPS. Using examples from Panduit, it explores each component’s role and selection criteria. The article also explains how to implement these components to ensure reliability, safety, and compliance with industry standards.

Space-efficient control panel design through wiring duct selection

To design an efficient control panel, automation and control engineers must contend with a variety of factors, such as cable segregation, thermal management, cable entry, electromagnetic interference (EMI), cable bend radius, and future expansion space. Wiring ducts play a critical role in this process, as they form the “skeleton” of the overall panel design. When selecting a wiring duct for an industrial control panel, a designer should consider the following factors:

- Panel design: The dimensions, type of panel, and specifications such as busbar size and cooling capacity all impact the type and the characteristics of the wiring duct needed.

- Size: The wiring duct should allow some space for future additions or adjustments. It should not be so large, however, as to unnecessarily take up space in the control panel.

- Type of wiring: Wires with different sizes and functions (such as power, control, or data cables) may need different kinds of ducts or channels for proper fit.

- Environment and materials: Common materials include polyvinyl chloride (PVC) and acrylonitrile butadiene styrene (ABS) plastic, but some conditions like high temperatures, moisture, or corrosive substances require ducts made of specific materials or with certain protective features.

- Installation and maintenance: It should be easy to add or remove wires, and the duct should be easy to install in the control panel.

- Compliance: The duct should meet applicable safety standards, electrical codes, and industry-specific regulations.

Standards and regulations are particularly important, as using a non-compliant wiring duct could result in safety hazards or failure of the control panel. As an example of a standards-compliant part, Panduit’s F1X3LG6 slotted wiring duct is made of lead-free PVC with a continuous-use temperature rating of up to +122°F (+50°C). This fulfills the UL 94 flammability rating of V-0 and meets the NFPA 79-2007 section 13.3.1 requirement for flame-retardant material.

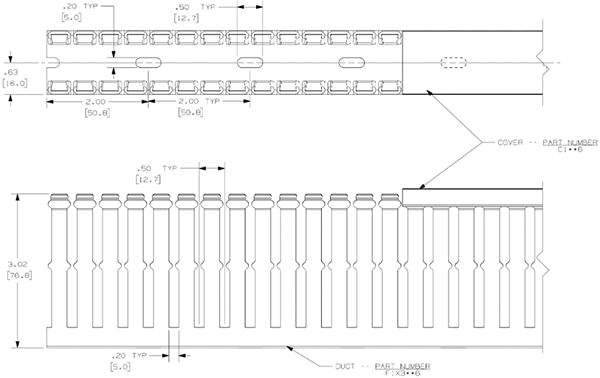

The F1X3LG6 is also well-suited to space-efficient designs. It has narrow slots that align with the spacing of high-density components, and it features score lines that facilitate the creation of larger holes for branching or other wire management (Figure 1). It is available with snap-on covers that provide quick and secure access to the wires.

Figure 1: The Panduit F1X3LG6 features narrow, closely-spaced slots with a double-restricted slot design for retaining wires. (Image source: Panduit)

Figure 1: The Panduit F1X3LG6 features narrow, closely-spaced slots with a double-restricted slot design for retaining wires. (Image source: Panduit)

Alternative wire routing solutions for control panels

Of course, ducts are not suitable for all situations. For example, wires may need to be routed through an area where a duct cannot be drilled into the chassis. In this scenario, solutions like the ABM100-A-C adhesive-backed cable tie mount can be considered. This four-way mount is designed for both quick installation and long-term reliability.

As with all adhesive systems, care should be taken to ensure that the correct adhesive is selected for the application environment (Figure 2).

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Figure 2: An adhesive system should be chosen to meet the demands of the application environment. (Image source: Panduit)

Protecting control panel wires and cables from abrasion

When wires are routed outside a duct, care should be taken to ensure that they are not damaged by abrasion or other hazards. For example, control panels typically require the routing of wires from within the enclosure to the front panel. These wires should be wrapped to avoid damage. Control engineers can select from options including:

- Spiral wrap: General purpose abrasion protection for wire harnesses and cable bundles. Allows easy breakouts and comes in different colors, materials, and sizes.

- Pan-wrap split harness wrap: Flexible and abrasion-resistant protection for wire harnesses and cable bundles. It has a unique slot pattern and a large overlap that reduces installation time and accommodates various bundle diameters.

- Braided sleeving: Continuous abrasion protection for wires, cables, hoses, and tubing. It has a flexible open weave that does not trap heat or humidity.

- Corrugated tubing: Economical solution with a solid wall design that provides complete protection of a cable bundle. It is available in different materials, some with a slit-wall design for easy installation and removal.

- Heat shrink: Good for insulating, protecting, and color-coding wires and cables. It can also be used with terminals and lugs for a clean, safe, and secure installation. It’s available in different materials, sizes, and wall thicknesses, some with adhesive lining for a watertight seal.

Many factors play into the selection of an appropriate wrap (Figure 3). For example, if the application calls for a solution that is lightweight, flexible, and able to accommodate irregular shapes, the T25F-C spiral wrap is a good choice. This wire wrap is designed for ease of installation but is also durable and rated for use up to +122°F (+50°C).

|

Figure 3: Various types of wire wraps are available to meet different needs. (Image source: Panduit)

Improving control panel maintainability and safety with cable termination, management, and labeling

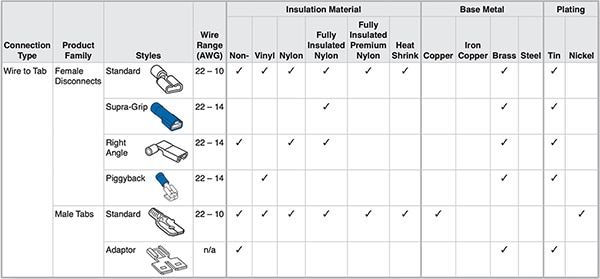

To ensure effective installation, use, and maintenance of a control panel, designers must choose the appropriate wire termination method and material (Figure 4).

Figure 4: Shown are examples of termination types and their features. (Image source: Panduit)

Figure 4: Shown are examples of termination types and their features. (Image source: Panduit)

The optimal choice depends on several factors, including the number of terminations required. For example, the DNF14-250FIB-C nylon insulated female disconnect can be inserted and removed from the male tab without the use of tools, leading to a lower installation cost and easier maintenance. In contrast, the FSD80-8-KD6 single wire DIN end sleeve insulated ferrule is designed for use with automated applicators that are better suited to high-count terminations.

Cable ties also play an important role in safety and maintenance by keeping wiring organized and secure. There is a wide variety of ties to meet different needs, as shown in Figure 5. Beyond the basic design of the tie, material selection is a critical consideration. For example, the PLT1.5M-M locking cable ties are made from Nylon 6.6 and, as such, are best suited to indoor use. For outdoor applications with hazards such as salt and acid rain, a material like propylene would be better.

Figure 5: Material selection for cable ties requires careful consideration of a wide range of environmental factors; the PLT1.5M-M locking cable ties use Nylon 6.6 and are best suited to indoor use. (Image source: Panduit)

Figure 5: Material selection for cable ties requires careful consideration of a wide range of environmental factors; the PLT1.5M-M locking cable ties use Nylon 6.6 and are best suited to indoor use. (Image source: Panduit)

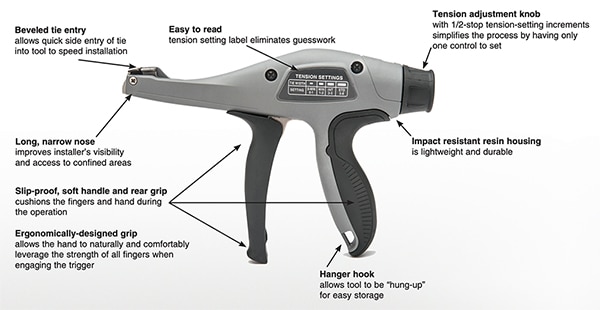

Using appropriate cable tie tools can improve productivity, reduce costs, and enhance worker safety. For example, the GTH-E cable tie gun is designed for ease of use (Figure 6). It requires 15% less handle force than similar tools, and its cable tie cut-off mechanism reduces the impact on the user’s hand by more than 40%.

Figure 6: Shown are the key features of the GTH-E cable tie gun, which was designed for ease of use. (Image source: Panduit)

Figure 6: Shown are the key features of the GTH-E cable tie gun, which was designed for ease of use. (Image source: Panduit)

Finally, clear labels are crucial for proper use and maintenance of a control panel. The choice of label depends not only on the intended use, but also the environmental hazards (Figure 7). If cables will only be exposed to mild, water-based liquids, for example, a solution like the S100X150VATY thermal transfer vinyl self-laminating label works well. These labels are sized specifically for wire and cable applications and are rated for use up to +150°F (+65°C).

Figure 7: Shown are samples of labeling solutions and their suitability for various environmental hazards. (Image source: Panduit)

Figure 7: Shown are samples of labeling solutions and their suitability for various environmental hazards. (Image source: Panduit)

Solutions like the TDP43ME thermal transfer printer can help ensure proper labeling (Figure 8). This thermal transfer printer allows operators to place labels on wires and cables as close as 1/2" (12.7 millimeters (mm)) from the end of connectors and terminals. The printer offers cycle times that are up to three times faster than traditional manual installation and twice as fast as competitive solutions. Its ergonomic design reduces operator fatigue and minimizes the risk of repetitive motion injury.

Figure 8: The TDP43ME thermal transfer printer comes with software and accessories for efficient labeling. (Image source: Panduit)

Figure 8: The TDP43ME thermal transfer printer comes with software and accessories for efficient labeling. (Image source: Panduit)

Grounding and safety in control panel applications

Considering the high power present in industrial control panels, proper grounding is crucial for safety. Selecting a ground bar is thus a critical design choice—one that can impact not only safety but also the cost-effectiveness and maintainability of a control panel.

The UGB2/0-414-6 universal ground bar illustrates this point. It is a part of the Panduit patented StructuredGround™ Universal Ground Bar System (UGB), which is compatible with all types of wire termination methods and over 140 connectors. This flexibility considerably simplifies design and maintenance. Furthermore, two stand-off mounting options are available, providing extra wiring space in tight areas.

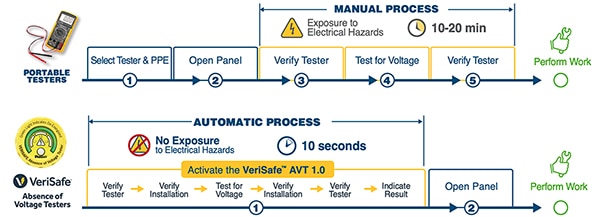

Safety and productivity are sometimes at odds. For example, regulations mandate a test to confirm the absence of voltage before servicing electrical equipment. This can be a time-consuming process with hand-held instruments. The VS-AVT-C02-L03 VeriSafe absence of voltage tester simplifies matters by automating the procedure. Once this device is installed into the front panel, a single button press allows workers to confirm the absence of voltage (Figure 9).

Figure 9: Automated testing using instruments such as the VS-AVT-C02-L03 VeriSafe absence of voltage tester is not only faster but also safer. (Image source: Panduit)

Figure 9: Automated testing using instruments such as the VS-AVT-C02-L03 VeriSafe absence of voltage tester is not only faster but also safer. (Image source: Panduit)

Maintaining reliable networking and avoiding tampering with industrial ethernet solutions and UPS

Data networks are now a part of most control panel designs. To avoid security breaches and downtime, whether due to tampering or misuse, it is important to ensure that network cables remain in place. The PSL-DCJB RJ45 jack module block-out devices were created to this end. These devices are inserted into unused Ethernet ports, only giving access to authorized workers who can remove the plugs with a specialized tool. Conversely, lock-in devices prevent the removal of network cables from active Ethernet ports.

In some cases, an Ethernet port must be accessible from the exterior of the control panel. Here, solutions like the IAEBHC6 IndustrialNet Cat 6 UTP bulkhead RJ45 coupler module with a protective cap play a valuable role. This bulkhead provides an IP67-rated seal that provides protection from dust and temporary immersion in water, making it suitable for work cells requiring washdown.

For network-powered devices, the Ethernet plugs require special features. For example, the FPS6X88MTG IndustrialNet, Category 6A shielded, field terminable RJ45 plug is designed for Power-over-Ethernet (PoE) and similar applications, per IEEE 802.3af/802.3at (PoE/PoE+). Among other features, this plug exceeds ANSI/TIA 568-C.2 Category 6A and ISO 11801 Class EA Channel performance requirements, and adheres to ANSI/TIA-1096-A (formerly FCC Part 68), IEC 60603-7, and IEC 60529 (IP20) standards.

Regardless of the source of power, many control panels require an uninterruptible power supply (UPS) to maintain functionality in the face of outages. When selecting a UPS for a control panel, control engineers should consider the following:

- Power capacity: The output should exceed the control panel’s power consumption.

- Maintenance: Remote management enables monitoring and control of key parameters, saving cost and time.

- Mounting: Options like DIN rail mounting ease integration into control panels.

- Safety and compliance: At a minimum, the UPS should meet relevant standards such as UL508.

The UPS00100DC industrial network UPS demonstrates a number of ways to go beyond these basics. It uses ultracapacitors instead of batteries, decreasing the risk of downtime and avoiding potential hydrogen gas buildup. The no-battery design is maintenance-free, delivering 2X better ROI and 50 to 70% lower cost of ownership than a battery-based UPS.

Conclusion

Designing industrial control panels is a demanding and intricate process that involves balancing space, security, safety, and reliability. To achieve optimal results, designers need to use control panel solutions that can help them organize, wire, and label their panels, as well as shield them from external and internal hazards. These solutions should be tailored to the specific requirements of industrial control panel applications and should come with installation and maintenance tools that guarantee proper operation. By using control panel solutions that meet these criteria, designers can build panels that are effective, secure, safe, and compliant.

Disclaimer: The opinions, beliefs, and viewpoints expressed by the various authors and/or forum participants on this website do not necessarily reflect the opinions, beliefs, and viewpoints of DigiKey or official policies of DigiKey.