How Sensor Fusion Can Enhance Battery Management System Performance and Battery Lifetimes

Sensor fusion can be a highly useful tool when designing battery management systems (BMSs) for applications like electric vehicles (EVs), residential and utility-scale battery energy storage systems (BESSs), and autonomous mobile robots (AMRs). For example, in order to maximize battery performance and lifetime, state of charge (SoC) and state of health (SoH) are important characteristics that need to be monitored and managed by the BMS. To get a handle on the SoC and the SoH of a battery, you can apply sensor fusion techniques that combine voltage, current, and temperature measurements in real-time.

For optimum results, however, the sensors in the BMS need to be highly accurate and environmentally rugged. Even small sensor errors can have a cumulative effect over time that results in incorrect estimations of SoC and SoH. In addition, the calculations for SoC and SoH must consider rates of charge and discharge, along with the temperature history of the cells. Each of these challenges can be addressed with sensor fusion.

Let’s take a quick look at what’s meant by SoC and SoH and the methods for calculating them, including the impact that temperature variations can have on accuracy. We’ll then look at how sensor fusion can improve BMS performance, and present some examples of voltage, current, and temperature sensors you can use for automotive and industrial BMS designs.

What are SoC and SoH?

SoC is simply the amount of charge in a battery. Lithium (Li) batteries have very flat discharge curves, and their voltage is nearly constant until they are about 80% discharged, so measuring the output voltage is not a useful way to measure SoC. To measure SoC, the BMS needs to monitor current flow and measure coulombs in and out of the battery.

While SoC is a measured quantity, SoH is an estimate of the battery’s existing capacity as a percentage of its capacity when it was new. Numerous algorithms have been developed for estimating SoH, and all rely on sensor fusion. Some common parameters used in SoH algorithms include:

- Impedance

- Self-discharge rate

- Ability to accept a charge

- Number of charge/discharge cycles

- Age of the battery

- The temperature history of the battery

- Cumulative energy charged and discharged

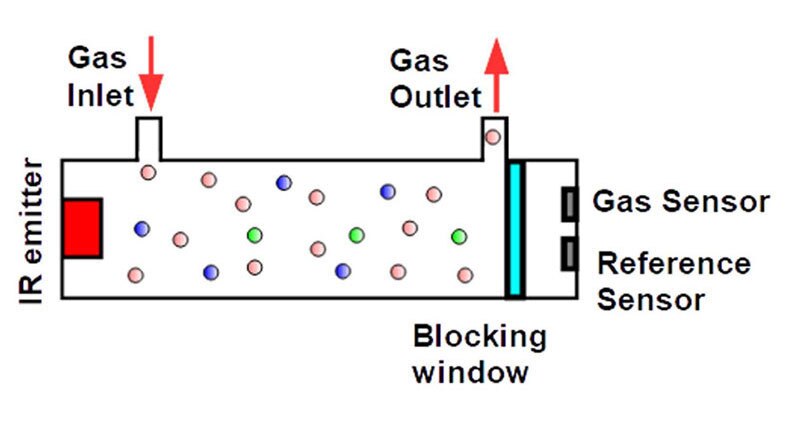

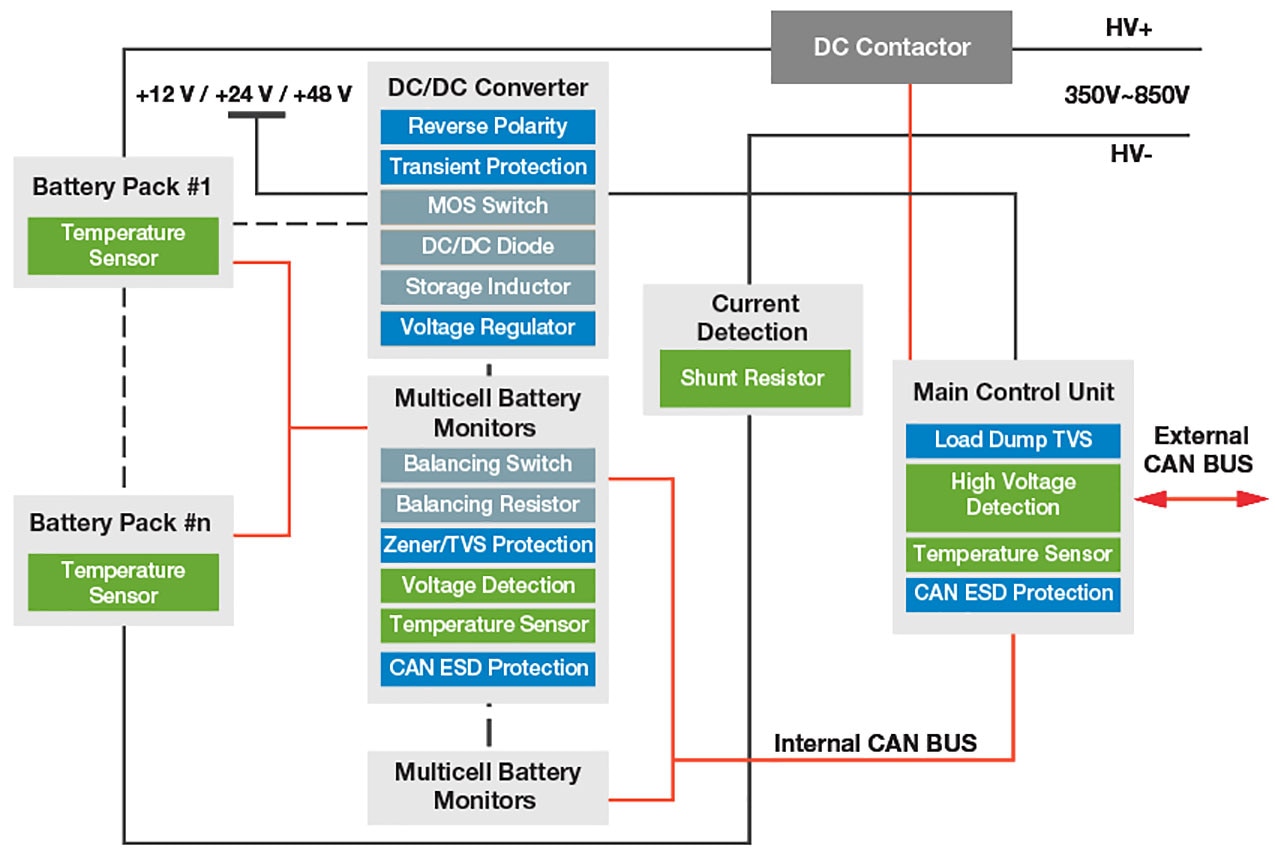

Sensor fusion for SoC and SoH is implemented using sensors distributed throughout the battery system, including temperature sensors in individual packs, voltage and temperature sensors in multicell battery monitors, current monitors in the high-voltage (HV) power distribution bus, and centralized high-voltage detection and temperature sensors in the main control unit (Figure 1). For accurate SoC and SoH calculations, you need sensors that are highly accurate and stable over time, and able to operate in harsh conditions.

Figure 1 : A variety of temperature, voltage, and current sensors (green boxes) are needed to support sensor fusion in a BMS. (Image source: Vishay)

Figure 1 : A variety of temperature, voltage, and current sensors (green boxes) are needed to support sensor fusion in a BMS. (Image source: Vishay)

The good news is that Vishay offers a wide range of components to support your BMS design activities. The following sensors just scratch the surface.

HV bus current detection

The WSLP series resistors are well-suited for use as HV bus current detection shunts. They support high-accuracy sensing in high-temperature applications with temperature coefficients as low as 75 parts per million per degree Celsius (ppm/°C), and a thermal electromotive force (EMF) of under 3 microvolts (µV) per °C. They are available with resistance values from 0.0002 to 0.1 ohms (Ω). Another choice for HV bus current detection are the WSBS/WSBM power shunts, with resistance values down to 25 micro ohms (µΩ) that can handle pulses greater than 2 kiloamperes (kA). Additionally, the WSK1216 power metal strip resistors have a four-terminal design, with a 1% tolerance and values down to 0.0002 Ω.

Voltage detection

Thin film chip resistors like the MCA1206MD5004BP500 5 mega Ω (MΩ) device can be used for HV detection in the main control unit and in battery monitors. Resistor values from 1 Ω to 10 MΩ are available in this family of automotive-grade devices. They are available with operating temperature ranges of -55 to 175°C and temperature coefficients as low as ±10 ppm per degree Kelvin (ppm/K). The TNPW high-stability, thin-film chip resistors are designed for use when precision and long-term stability are required. They have a low resistive drift of ≤0.05% after a 1000 hour life test.

Temperature sensors

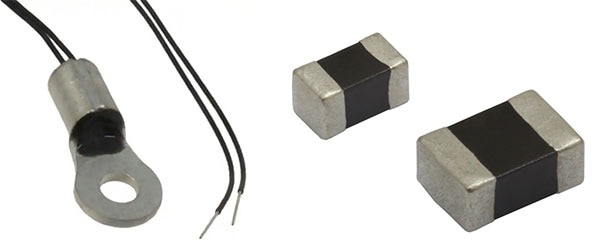

Vishay also offers a variety of temperature sensors suited for specific BMS applications, such as the NTCALUG series lug temperature sensors that are designed for surface-temperature sensing applications (Figure 2). They combine electrical insulation and solid thermal contact, providing accurate and dependable measurements from -40 to +150°C.

Battery monitor circuits and main control unit designs can benefit from the NTCS series of surface-mount NTC thermistors that are encased in glass for environmental protection. They enable high-sensitivity and high-accuracy sensing from -40 to +150°C. They use ceramic-based technology and are available in three sizes: 0402, 0603, and 0805.

Figure 2: Vishay offers a variety of temperature sensor packaging styles, including lug (left) and surface-mount (right) NTC temperature sensors (not to scale). (Image sources: Vishay)

Figure 2: Vishay offers a variety of temperature sensor packaging styles, including lug (left) and surface-mount (right) NTC temperature sensors (not to scale). (Image sources: Vishay)

Conclusion

Sensor fusion is useful in a BMS to measure voltages, currents, and temperatures to enable accurate determination of battery SoC and SoH, extend battery lifetime, and maximize battery system performance. As shown, Vishay offers a complete range of environmentally rugged and precise sensors and other components suitable for high-performance BMS designs.

Recommended Reading

Why and How to Use Battery Management ICs for Stacked Cells

Monitoring Lithium-ion Battery Packs to Detect Battery Thermal Runaway Events

Have questions or comments? Continue the conversation on TechForum, DigiKey's online community and technical resource.

Visit TechForum