How Are Electric Vehicle Battery Packs Manufactured?

Contributed By DigiKey's North American Editors

2023-04-14

The battery pack is a critical subassembly in all-electric vehicles (EVs), and it’s one of the most complex to assemble. It starts with testing the individual battery cells before assembly. Next, collaborative robots (cobots) are often used to assemble the battery modules and then integrate the modules into completed battery packs, including the bus bars, cooling assemblies, battery management, and other subsystems. Finally, an automated visual inspection system is needed to ensure that all the elements in the assembly are properly put together.

This article reviews the complexities of EV battery packs and some related subassemblies, including the need for numerous battery cell modules, electrically efficient and lightweight bus bars and wiring harness interconnections, and an active cooling system. It then presents representative products from DigiKey, including a data acquisition device from National Instruments that can be used as part of the battery cell testing system, a cobot from Omron Automation that can be used for battery pack assembly, and a smart camera module with embedded software from Banner Engineering that can provide an automated inspection platform.

EV battery pack building blocks

EV battery pack design varies from one manufacturer to another and sometimes from one model of EV to another at the same manufacturer making flexible assembly an important consideration. One thing all EV battery packs have in common is that they can use thousands of components.

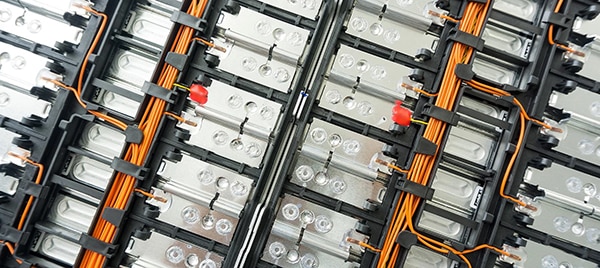

EV battery packs consist of numerous battery modules that are assembled into the final pack (Figure 1). The architecture of the modules and packs is evolving to deliver higher voltages to the EV drive train. While 400 VDC has been the standard, voltages up to 900 VDC appear more often. The main benefit of higher voltages is faster charging. Faster charging can help reduce the range anxiety of EV drivers but makes the battery packs more challenging (and potentially dangerous) to assemble.

Figure 1: Battery modules are the fundamental building blocks of EV battery packs. (Image source: National Instruments)

Figure 1: Battery modules are the fundamental building blocks of EV battery packs. (Image source: National Instruments)

The battery cells in a module are often welded together, while the modules are generally bolted to large busbars to form the completed battery pack. The architecture of the modules versus the pack is often a differentiating factor between EV designs. In all cases, the battery system needs thermal management, mainly cooling but occasionally heating when the ambient temperature is too low for efficient battery operation. The thermal management system may be passive for small packs, but large packs require active thermal management with phase change devices and pumps to circulate liquid to cool individual cells.

A battery management system (BMS) monitors the state of health and charge of individual battery cells. The BMS includes a range of voltage, current, temperature, and other sensors, often with sensors positioned on each battery cell. The BMS communicates with the central computer system of the EV.

Fuses are sometimes used at the module level, but there’s always over-current protection for the overall battery pack. A large high-voltage contactor and other components are used to precharge the motor drive circuit to prevent potentially damaging high inrush currents when the EV is first turned on. A service disconnect interlock isolates the high voltages in the battery pack and provides a safe environment for service technicians working on the EV. Hundreds of screws, nuts and bolts, connectors, and other mechanical components are needed to complete the assembly.

Building battery packs

Testing individual battery cells is a crucial first step. It’s usually the last step in the cell production process at the specialized gigafactory, where the cells are manufactured. But when the cells arrive at the EV production facility, it’s also common for random quality assurance testing to occur to monitor the quality levels of incoming batches of battery cells. Without high-quality battery cells, producing high-quality and reliable EV battery packs is impossible.

Next, the cells are assembled into modules. Modules usually consist of about 12 to 20 cells. The modules are stacked in a metal frame that provides interconnections, protection from shock and vibration, and in some models, thermal management. Precision is required, and as the battery pack assembly is built up, it gets progressively heavier until it weighs hundreds of pounds.

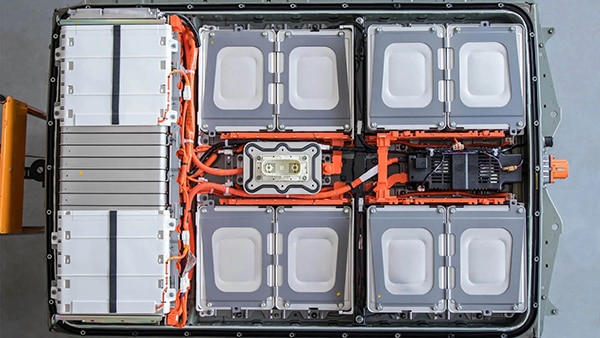

Because of the need for precision and handling heavy loads, battery pack assembly is often performed using cobots or industrial robots. A cobot can handle heavy loads and rapidly and accurately assemble the hundreds of screws, connectors, and other components needed for the completed pack. For example, the battery pack in a Nissan Leaf includes 48 modules (Figure 2). The final step in battery pack assembly is automated testing, including visual inspection of the complex pack.

Figure 2: This Nissan Leaf battery pack includes 48 battery modules plus hundreds of other components. (Image source: NHR division of National Instruments)

Figure 2: This Nissan Leaf battery pack includes 48 battery modules plus hundreds of other components. (Image source: NHR division of National Instruments)

Battery testing and data acquisition

Manufacturing engineers designing battery test systems can turn to the 779640-01 data acquisition (DAQ) device from National Instruments. This full-speed USB 2.0 DAQ includes eight ±60 volts direct current (VDC) channels for isolated digital inputs, eight 60 VDC, 30 volts root mean square (VRMS) channels for isolated solid-state relay (SSR) outputs, and a 32-bit counter (Figure 3). The eight isolated inputs include an optocoupler, a Schottky diode, and a depletion-mode MOSFET-based current-limiting circuit. The 779640-01 also includes digital filtering, change detection, programmable power-up outputs, and a watchdog timer.

Figure 3: The 779640-01 DAQ includes eight isolated digital inputs (right side) and eight isolated SSR outputs (left side). (Image source: DigiKey)

Figure 3: The 779640-01 DAQ includes eight isolated digital inputs (right side) and eight isolated SSR outputs (left side). (Image source: DigiKey)

The 779640-01 DAQ can monitor changes, including rising edges, falling edges, or both, on specific input lines or all input lines at once. An interrupt is generated when a change is recognized. The interrupt does not indicate the input line on which the change occurred. The software can be used to read the lines and determine the source of the change notification. Digital filtering can minimize the effects of noise and electromagnetic interference (EMI).

The digital filter works on the optocoupler inputs. Optocouplers turn off slower than they turn on, passing falling edges slower than rising edges. The digital filter can help eliminate changes caused by noise or EMI. Designers can configure the filter channels with programmed filter intervals. Pulses shorter than half of the programmed filter interval are blocked. Pulses that are longer than the filter interval are passed through. Pulses in between may or may not pass through the filter.

Getting help with heavy loads & repetitive tasks

Once the battery cells have been passed through testing, a cobot can speed up the battery module and pack assembly process. Assembly involves multiple processes, and cobots like the RT6-1001321 from Omron Automation are highly adaptable (Figure 4). The RT6-1001321 has an integrated Fieldbus adapter to facilitate integration into factory automation systems. Cobots operate with high precision and can assist with screwdriving, gluing, applying thermal greases, mating connectors, and a myriad of other activities needed to put together an EV battery pack. Some capabilities that make cobots well-suited for EV battery pack assembly include:

- Graphical programming environments to speed cobot training.

- Integrated vision systems assist in inspection and measurement of the results as well as with the assembly activities.

- Modular end effectors can be rapidly changed, enabling a single cobot to perform a range of assembly processes.

- Cobots can operate interactively with logistics and other mobile robots to form a complete manufacturing cell for battery packs.

Figure 4: Cobots like the RT6-1001321 are highly adaptable and can perform repetitive tasks rapidly with high precision. (Image source: Omron Automation)

Figure 4: Cobots like the RT6-1001321 are highly adaptable and can perform repetitive tasks rapidly with high precision. (Image source: Omron Automation)

Flexibility and the ability to be quickly taught new procedures, avoiding extended downtime and inefficient production periods, are key cobot attributes. A new activity can be taught in a few minutes using a graphical user interface or simply moving the cobot arm from position to position. Cobots excel at repetitive tasks common in EV battery pack assembly and can handle heavy loads precisely. Finally, cobots can include machine vision and artificial intelligence (AI) to pick up the required parts in the correct orientation, add them to the battery pack assembly, and inspect the results.

Verifying the results

Automated visual verification that the battery pack has been properly assembled can be performed using the VE205G1A smart camera from Banner Engineering (Figure 5). The integrated software is designed to perform advanced visual inspection functions. Banner’s vision manager software is included with the VE205G1A and provides several tools like item detection, positioning and feature measurement and flow analysis, and barcode reading to speed the development of vision applications. Runtime editing supports real-time changes to an inspection routine, reducing downtime and speeding up results. Some of the capabilities of the VE205G1A smart camera include the following:

- EtherNet/IP, Modbus/TCP, PROFINET, and RS-232 connectivity for easy integration into factory automation systems

- Six optically isolated inputs/outputs (I/O) and an external light connector

- Two-line, eight-character display that provides camera status and enables fast changeovers to new activities.

- Optional sealed lens covers deliver IP67 ratings for harsh industrial environments.

- Typical uses include:

- Presence or absence of parts, including counting the number of items and verifying labeling.

- Verifying the orientation of a part and sending part location and orientation to a pick-and-place robot or cobot.

- Flaw detection including identifying the location and size of flaws on an item.

- Measuring critical dimensions of an item or the relative locations of items in an assembly.

Figure 5: Smart cameras like the VE205G1A provide all the functionalities needed for rapid visual inspection of EV battery pack assemblies. (Image source: Banner Engineering)

Figure 5: Smart cameras like the VE205G1A provide all the functionalities needed for rapid visual inspection of EV battery pack assemblies. (Image source: Banner Engineering)

Summary

EV battery packs are complex and critical subsystems. An EV’s performance, reliability, and cost are strongly correlated with the ability to efficiently and quickly assemble the battery pack. The assembly process begins with verification that the battery cells meet the required specifications, then relies on automated precision assembly using robots and cobots, and ends with a final visual inspection using smart, automated cameras.

Disclaimer: The opinions, beliefs, and viewpoints expressed by the various authors and/or forum participants on this website do not necessarily reflect the opinions, beliefs, and viewpoints of DigiKey or official policies of DigiKey.