Easy Automation with Omron TM Collaborative Robots

The competitive manufacturing environment and ongoing labor shortages have increased the demand for immediate robotics solutions. However, traditional industrial robots have been limited by their programming complexity, safety risks, and the need to redesign workspaces around them. The Omron TM Collaborative Robot (cobot) addresses these pain points by being quick to deploy and easy to reconfigure.

Users can automate repetitive tasks by hand guiding an Omron TM cobot. (Image source: Omron)

Users can automate repetitive tasks by hand guiding an Omron TM cobot. (Image source: Omron)

Achieve Motion in Minutes

The Omron TM Collaborative Robot can be programmed in a matter of moments thanks to TMFlow, a graphical programming environment that requires no prior programming experience. TMFlow is a visualized flow-based software in which users can click and drag visual code instructions into a flowchart-like program. Users can also create programs by hand-guiding the robot to set points and assign tasks to the cobot. Using buttons built into the cobot’s wrist, users can guide the robot to desired positions and automatically record positions and tooling actions into TMFlow. TMFlow has turned developing and adjusting controls programs into a painless process.

Projects are easy to create in TMFlow thanks to being able to click and drag instructions into a graphical flow-based programming environment. (Image source: Omron)

Projects are easy to create in TMFlow thanks to being able to click and drag instructions into a graphical flow-based programming environment. (Image source: Omron)

Vision tasks can also be easily developed thanks to TMFlow and the cobot’s integrated camera and light. Vision tasks can be added while performing hand-guided motion programming thanks to a dedicated Vision button on the cobot’s wrist. Pre-written vision instructions can be effortlessly added and configured manually in TMFlow to accomplish tasks including pattern matching, bar code reading, color classification, and more. TMFlow’s visual click-and-drag programming environment and the ability to program by hand-guiding the cobot enables users with little-to-no programming experience to create complex robotics applications.

Simplify Safety

The Omron TM Collaborative Robot is designed to satisfy the requirements of ISO/TS 15066, which outlines safety requirements for collaborative industrial robot systems. This is complimented by guided safety setup wizards within TMFlow which allows users to automatically generate application-appropriate safety parameters without the need to understand complicated safety calculations. These considerations, in conjunction with an application-specific risk assessment, can allow the cobot to share workspaces with humans and lower the number of additional gates, barriers, and safety devices required. This not only reduces the effective footprint of a robot, but also enables human and robot collaboration to combine human ingenuity and problem solving with the productivity of automation.

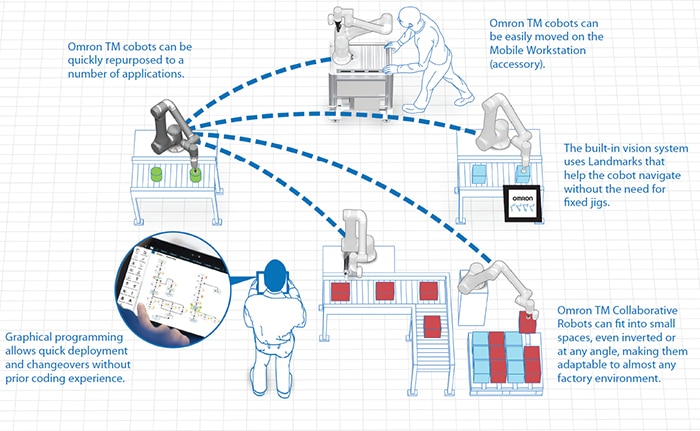

Find Flexibility with Cobots

All the aforementioned features enable the robot to be easy to adapt for dynamic and evolving operations and environments. The cobot can be moved between various workspaces, either by mounting it to a new surface or moving it atop an optional Mobile Workstation. After repositioning, the cobot’s built-in vision system can utilize visual Landmarks to redefine the cobot’s reference position without the need to rigidly mount it to a specific, fixed location. TMFlow allows application changeover and new deployments to be accomplished with minimal downtime. Together with the ease-of-use programming and inherent safety design, these features allow Omron TM Collaborative Robots to be easily redeployed between various applications, making production flexible without compromising safety and uptime.

Omron TM Collaborative Robots can be easily relocated and reconfigured to work within different workstations with minimal downtime. (Image source: Omron)

Omron TM Collaborative Robots can be easily relocated and reconfigured to work within different workstations with minimal downtime. (Image source: Omron)

Options and Accessories for any Application

The Omron TM Collaborative Robot is available with several options to address the needs of different work environments and applications. The cobot is available with either a 100-240 VAC (50-60 Hz) or 22-60 VDC power supply to meet the existing power availability of a workspace or to enable the cobot to be repositioned. The cobot is available in various reach (700mm to 1300mm) and payload (4kg to 14kg) specifications. This wide range of options allow the perfectly sized cobot to be chosen for each job. SEMI S2 certified models are available for sensitive electronics-related environments. Finally, software licenses can be purchased to enhance the feature suite of TMFlow, including offline editing and the ability to add external cameras.

The Omron TM Collaborative Robot is also supported by an ever-growing Plug & Play ecosystem of 3rd party devices and software. This ecosystem includes grippers (mechanical and vacuum), connectivity devices, and application accessories including force sensors and external cameras. These products are available with prewritten TMFlow components that can easily be added to projects with minimal software configuration necessary. These options further expand the flexibility of the cobot line to match the needs of different applications of varying scales.

The Plug & Play ecosystem streamlines the process of finding and integrating the ideal cobot accessories for your application. (Image source: Omron)

The Plug & Play ecosystem streamlines the process of finding and integrating the ideal cobot accessories for your application. (Image source: Omron)

The Omron TM Collaborative Robot line of cobots can enable your automation solutions to be easy to integrate and reconfigure, allowing your personnel to focus on value-added activities that require human intelligence. It’s never been easier to introduce automation to your processes thanks to the Omron TM Collaborative Robot line’s ease of programming, integrated vision, and workspace footprint sharable with human workers. Now is the perfect time to learn more about Omron’s cobot offerings and how they can improve your business processes.

Have questions or comments? Continue the conversation on TechForum, DigiKey's online community and technical resource.

Visit TechForum