NPI Blog - Omron Automation - Predictive Maintenance

Real-time predictive machine monitoring: an effective way to reduce costs

Preventive or over-maintenance is a common methodology intended to prevent legacy machine downtime, but it can come at great cost by facilitating the replacement of “good” components and offers no assurance that the replacement parts are superior to those replaced. Although superior to a “Fix it when it breaks” approach, both methods are costly from a repair and down-time cost standpoint.

With Omron Automation’s wide selection of devices and systems designed for predictive maintenance solutions, vital in-service machines can run longer between maintenance cycles with an additional reduction in troubleshooting time and technician labor. Slowly taking hold over recent decades, predictive maintenance (PdM) leverages sensors and other monitoring devices that provide continuous real-time information at the site or remotely using IIoT solutions or wireless networks to reduce wiring costs.

PdM systems monitor the immediate and actual condition of vital machine components to determine when maintenance is required. Data collection and fault detection are key components to predicting and preventing failures leading to more reliable machinery and systems. Aside from cost savings, plant safety is increased, and the risk of potential accidents involving personnel or the environment is greatly reduced.

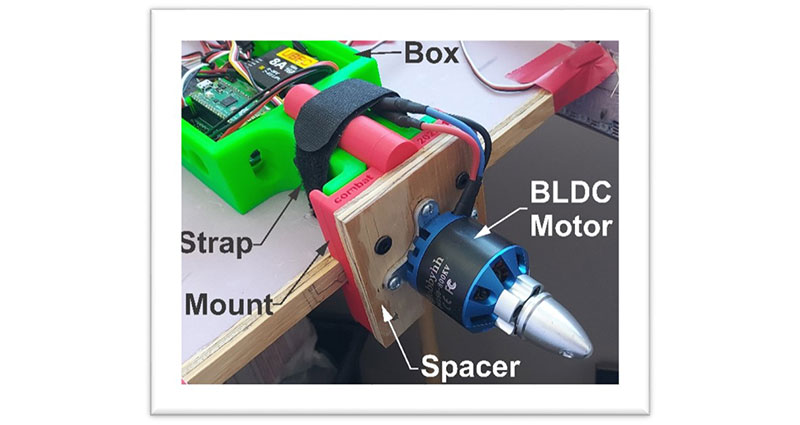

Examples of Omron’s S8VK-X Series power supplies, K6CM series motor controllers, and K6PM thermal imager (left to right). (Image source: Omron Automation and Safety)

Examples of Omron’s S8VK-X Series power supplies, K6CM series motor controllers, and K6PM thermal imager (left to right). (Image source: Omron Automation and Safety)

Omron’s S8VK-X series power supply, as an example, monitors DC voltage, DC run current, and peak current, logs run time and calculates replacement time in effective PdM applications. Other products such as the K6CM motor condition monitors keep track of vibration, temperature, current, and insulation resistance (ground fault). To monitor temperature, Omron offers the K6PM thermal imager. Utilizing sensor monitoring with measurement of process performance to determine right-time maintenance is mode of operation for Collaborative Process Automation Systems or CPAS.

Predictive maintenance programs involve run-time measurements compared to a known set of learned or known component data to glean and report electrical and mechanical anomalies. The programs require the automation of data collection and analysis, providing 24/7 condition monitoring in real-time delivered to the right location for immediate scrutiny. Omron predictive maintenance-oriented devices are designed to make these programs a reality.

Have questions or comments? Continue the conversation on TechForum, DigiKey's online community and technical resource.

Visit TechForum