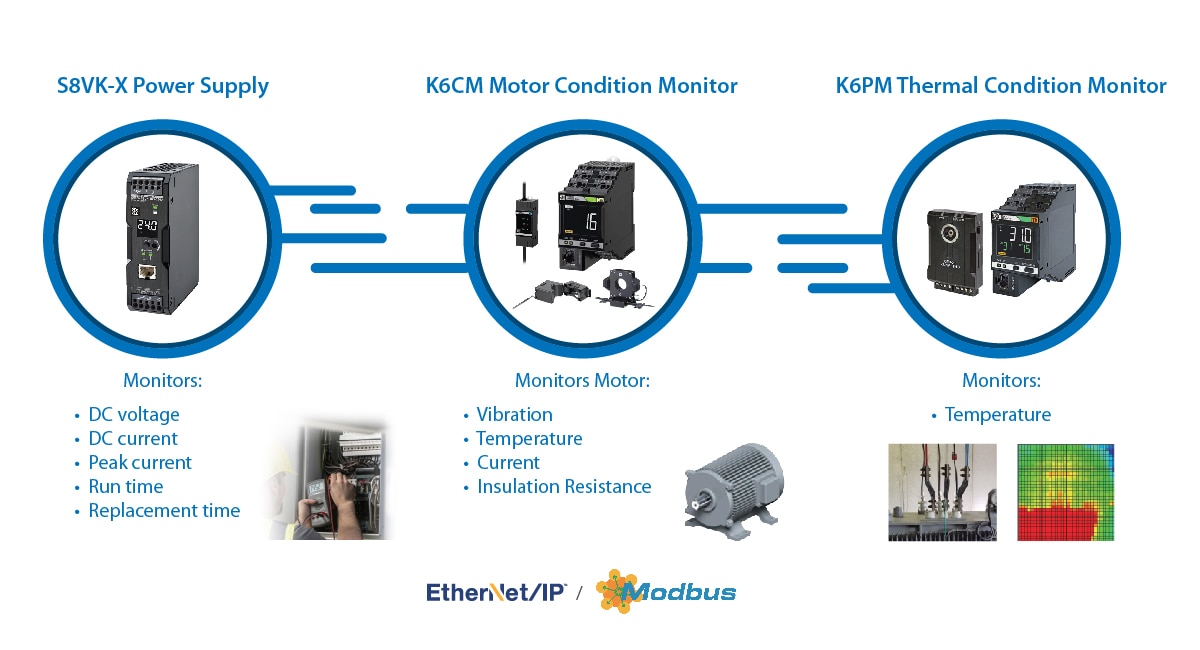

S8VK-X Power Supply

This single-phase power supply detects abnormal DC load conditions and calculates remaining power supply life based on the power supply load conditions. Its user-friendly local display provides easy status visualization and can be monitored remotely with the included PC monitoring software.