Monitoring Lithium-ion Battery Packs to Detect Battery Thermal Runaway Events

Battery packs that consist of multiple lithium-ion (li-ion) batteries pose a safety threat in electric vehicles (EVs) and power storage applications where there is a possibility of serious consequences due to thermal runaway. Users, of course, are generally oblivious to this, but designers are fully aware that with hundreds of individual li-ion battery cells that are series and parallel connected, a single cell failure can initiate a rapid increase in temperature and begin to vent gases and solid particulates.

This failure mode may spread to other battery cells. These additional reactions produce even more heat and gases until the entire battery system is affected and thermal runaway occurs.

Measures are in place to prevent this from happening, but should it occur, detecting a thermal runaway condition is critical. To this end, Honeywell Sensing and Productivity Solutions has developed the BAS series of automotive-grade battery aerosol sensors that use the principle of light scattering to detect and report thermal runaway events in li-ion battery packs. They use optical scattering to detect the presence and concentration of aerosols such as smoke, liquid, and debris which are early indicators of a thermal runaway event.

The process of optical scattering involves illuminating a volume of air. The particles inside the illuminated volume scatter the light, which is then measured by a light sensor to generate an electrical signal that is proportional to the density of the particles.

The BAS series measures and reports aerosol concentrations from 200 micrograms per meter cubed (μg/m³) to 10000 μg/m³. They have a factory-programmed, thermal runaway warning threshold of 5000 μg/m³ with a response time of less than 1 second. Control, data transfer, and alarm in the continuous operating mode are via the Controller Area Network (CAN) communications protocol, which is widely used in the automotive and vehicular environment. The CAN interface operates at a baud rate of 500 kilobits per second (kbps).

Example sensors

Honeywell Sensing and Productivity Solutions offers two sensors in the BAS series, the BAS6C-X00 and the BAS6C-H00 (Figure 1). The devices are physically identical with dimensions of 2.6 inches (in.) (66 millimeters (mm)) long, 1.42 in. (36 mm) deep, and 1.46 in. (37 mm) high.

Figure 1: Honeywell Sensing and Productivity Solutions offers two battery aerosol sensors—the BASC6X-X00 and BAS6C-H00—that are physically identical. The BAS6C-X00 is the Media Control Unit 1 (MCU1) version, and the BAS6C-H00 is the more recent Media Control Unit 2 (MCU2) version. (Image source: Honeywell Sensing and Productivity)

Figure 1: Honeywell Sensing and Productivity Solutions offers two battery aerosol sensors—the BASC6X-X00 and BAS6C-H00—that are physically identical. The BAS6C-X00 is the Media Control Unit 1 (MCU1) version, and the BAS6C-H00 is the more recent Media Control Unit 2 (MCU2) version. (Image source: Honeywell Sensing and Productivity)

The BAS6C-X00 is the Media Control Unit 1 (MCU1) version, and the BAS6C-H00 is the more recent Media Control Unit 2 (MCU2) version.

The BAS sensors function in either of two operating modes based on the state of the Request input line set by the battery management system (BMS). The ECO mode, when the Request line is held low (less than 0.5 volts), is the economy mode and minimizes power drain. The sensor wakes up and is operational for 200 milliseconds (ms), and then it hibernates for the next 12,000 ms to save power. Additional power savings are obtained by disabling the CAN bus. If a threshold event occurs, i.e., a particulate concertation in excess of 5,000 mg/m3, the sensor sends a wake-up signal to the BMS to initiate a full battery-system check.

In continuous mode, when the BMS sets the Request line high (between 8 to 16 volts), the sensor constantly monitors and reports the aerosol concentration to the BMS using an 8 byte message over the CAN bus.

Both versions operate from a nominal 12 volt supply voltage, with a range of 8 to 16 volts. The supply current depends on the operating mode. It is less than 0.5 milliamperes (mA) in ECO mode and less than 30 mA in continuous mode.

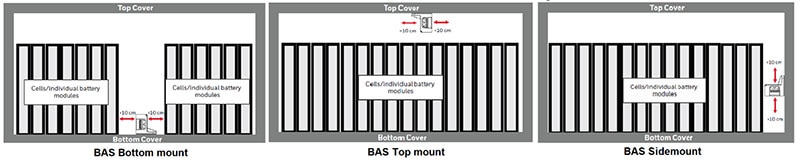

The sensors can be mounted in any orientation within the enclosed battery pack as long as a 10 centimeter (cm) clearance is provided on both sides of the hollow sensing chamber (Figure 2).

Figure 2: BAS sensors can be mounted anywhere within the battery pack. In all cases, the battery pack vent valve must be unblocked. (Image source: Honeywell Sensing and Productivity)

Figure 2: BAS sensors can be mounted anywhere within the battery pack. In all cases, the battery pack vent valve must be unblocked. (Image source: Honeywell Sensing and Productivity)

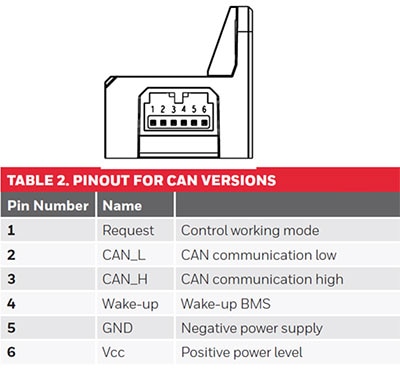

The interface connector is a six-pin rectangular socket with the designated pinouts shown in Figure 3.

Figure 3: The pinouts for the BAS series sensors include power, ground, Request and Wake-up signals, and the differential CAN bus signals. (Image source: Honeywell Sensing and Productivity)

Figure 3: The pinouts for the BAS series sensors include power, ground, Request and Wake-up signals, and the differential CAN bus signals. (Image source: Honeywell Sensing and Productivity)

The mating plug connector for the BAS series battery aerosol sensors is the 175507-2 from TE Connectivity AMP Connectors.

Conclusion

Early detection of li-ion battery pack thermal runaway using the Honeywell Sensing and Productivity Solutions BAS battery aerosol sensors has the potential to prevent injury, loss of life, and property damage. Using them also allows compliance with international recommendations and regulations, as they are designed to meet the highest quality and reliability standards.

Additional Resources

Have questions or comments? Continue the conversation on TechForum, DigiKey's online community and technical resource.

Visit TechForum