Choosing Thin Film Pyroelectric Sensors for Flame Detection and Gas Analysis

Increasing concern over greenhouse gases in the environment, along with the need to measure air pollution and detect fires, makes the identification and measurement of gases an area of great concern to many. Let’s look at how designers can address these concerns through the use of passive pyroelectric sensors suitable for gas and flame detection.

Infrared (IR) sensing

The ability to sense gases in the environment is a useful function. It is especially useful in the detection of environmentally sensitive gases like carbon dioxide (CO2) and carbon monoxide (CO). This same technology can be applied to flame detection because these same gases are the primary gases present in open flames. These gases, along with water vapor, hydro-carbons (H-Cs) like methane (CH4), and several others have significant absorption spectra in the mid-infrared range.

IR radiation has spectral components between those of microwaves and visible light, spanning the wavelengths between 0.76 micrometers (mm) and 1 millimeter (mm). This range is segmented into three distinct sub-regions: short wave, or near-IR, covering wavelengths of 0.76 to 3 micrometers (μm); medium wave, or mid-IR, in the 3 to 14 μm wavelength range, and long wave, or far-IR, covering 14 μm to 1 mm wavelengths.

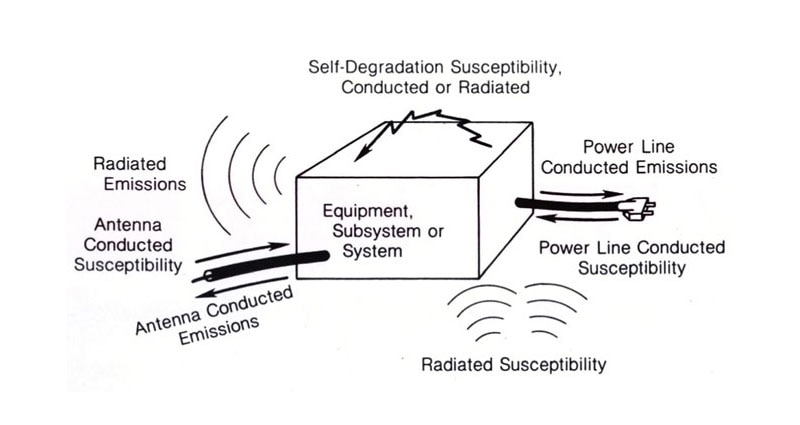

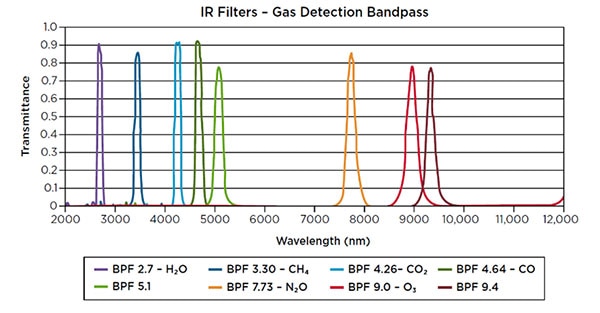

Most of the gases of interest have absorption spectra in the mid-IR range (Figure 1).

Figure 1: IR absorption peaks associated with different gases occurring in the mid-IR spectral range. (Image source: Broadcom)

Figure 1: IR absorption peaks associated with different gases occurring in the mid-IR spectral range. (Image source: Broadcom)

The principal gases emitted in open flames are CO2 and CO, so the same IR technology can be applied to detect flames.

IR detection

IR radiation can be detected in several ways. Photodiodes can be used in the near-IR range. Other traditional methods include the use of thermopiles, which are stacks of thermocouples that respond to heat radiation to produce a voltage proportional to the change in temperature due to IR energy.

More recently, sensors that make use of the pyroelectric effect are used in the mid-IR to long-IR spectrum segments. The pyroelectric effect is the ability of certain crystalline materials to generate a voltage across the crystal faces when they are heated or cooled. The sensor can be visualized as a capacitor that self-charges when subjected to IR radiation. Pyroelectric sensors have an advantage over thermopiles in that they have a faster response time, a superior signal-to-noise ratio (SNR), and are more sensitive due to their greater responsivity. Photodiodes, especially when measuring longer IR wavelengths, need to be cooled in order to achieve a good SNR. Pyroelectric sensors do not require cooling in the mid-IR to long-IR spectrum segments, giving them an advantage.

Pyroelectric materials, such as lead zirconate (PZT) or lithium tantalate (LiTaO3), can be used to create IR sensors. They can be used in bulk form or as thin film hybrid structures. Bulk pyroelectric devices generally exhibit poorer responsivity and poorer SNR relative to devices based on thin film techniques.

Thin film pyroelectric sensors generally include a high-gain amplifier to buffer the pyroelectric devices (Figure 2).

Figure 2: The packaging of a thin film pyroelectric sensor includes the sensor die, a high-gain amplifier, and an integrated optical IR filter. (Image source: Broadcom)

Figure 2: The packaging of a thin film pyroelectric sensor includes the sensor die, a high-gain amplifier, and an integrated optical IR filter. (Image source: Broadcom)

The amplifier is implemented as a low-noise CMOS operational amplifier (op amp) with a feedback resistor of up to 10 gigaohms (GΩ). The output signal is centered at half the supply voltage. The sensor offers a stable, fast response that operates over a wide frequency range.

The optical filter is used to limit the range of wavelengths over which the sensor responds. These filters essentially tune the sensor to specific IR wavelengths.

Thin film pyroelectric sensor applications

Thin film pyroelectric sensors in the mid-IR range are used across an extensive array of applications, including flame detection and gas analysis, as well as fuel and oil analysis, food safety, and environmental monitoring.

In flame detection applications, the IR sensors measure the IR radiation coming from the flame. The flame is covered with hot gases like CO2 and CO. The flame and its gaseous envelope are not static; they flicker at frequencies typically ranging from 1 to 15 hertz (Hz). IR sensors monitor the spectral range of the emitted gases at the flicker rate, thereby enabling precise detection of the open flame.

The key characteristics for flame sensing are field of view (FoV) and dynamic range, as indicated by the SNR. These parameters should be as large as possible. Flame detection is self-excited by the flame source and generally only uses single-channel IR sensors.

IR gas analysis is based on the absorption of an IR source by the selected gas. The process is referred to as nondispersive IR (NDIR) spectroscopy. An IR emitter is the source of broadband IR energy, that includes the absorption wavelength. Two IR sensors are used, with one filtered to measure the absorption wavelength of the selected gas, while a secondary sensor is filtered at a non-absorption wavelength to provide a reference signal (Figure 3).

Figure 3: Shown is a simplified diagram of a gas analysis setup that uses thin film pyroelectric sensors. (Image source: Broadcom)

Figure 3: Shown is a simplified diagram of a gas analysis setup that uses thin film pyroelectric sensors. (Image source: Broadcom)

A pulsed blackbody source, modulated at a 30 to 100 Hz rate, fills the gas tube with a suitable range of IR wavelengths. The gases in the tube will absorb IR energy based on their atomic structure. As an example, CO2 absorbs energy with a wavelength of 4.26 μm. A nearby wavelength of 3.9 μm that is not absorbed by the CO2 is selected as a reference wavelength. The reference channel monitors any variation in the power of the IR source. To reduce interference, a blocking optical filter restricts the range of wavelengths seen at the sensors to those associated with the gas absorption and the wavelength for the reference channel.

The four most common gases monitored are oxygen (O), CO, CO2, and nitrogen oxide (NO). IR sensors offer significant advantages over alternate methods, including long life, a fast response, no need for calibration, and the ability to detect and identify a wide range of gases.

Thin film pyroelectric sensors

Armed with this information, you may be interested in starting your own pyroelectric sensor design. If you’re wondering what devices are available, Broadcom offers off-the-shelf IR sensors based on its own thin film PZT IR technology. It has both analog single-channel and dual-channel IR detectors that are sensitive to discrete mid-IR wavelengths and intended for both flame detection and gas analysis applications.

The sensors are packaged in TO-39 cans and are well-suited to outdoor use in the heavy industrial, oil and gas, infrastructure, and forest protection industries where this is an important characteristic, along with FoV and SNR (Figure 4).

Figure 4: Examples of the TO-39 packaging of the single and dual-channel thin film pyroelectric sensors. (Image source: Broadcom)

Figure 4: Examples of the TO-39 packaging of the single and dual-channel thin film pyroelectric sensors. (Image source: Broadcom)

The sensors have a rated responsivity of 150,000 volts per watt (V/W) and feature an SNR of 10,000. All the sensors use single supply rails between 2.7 and 8 volts and have an operating temperature range of -40°C to +85°C (Table 1).

Thin film pyroelectric single-channel sensors

| Broadcom part number | Filter center wavelength (µm) | Filter half power bandwidth (nm) | Cut on wavelength (µm) | Cut off wavelength (µm) | Application |

| AFBR-S6PY3200 | 2.77 | -- | 2.425 | 3.115 | Flame detection |

| AFBR-S6PY2341 | 4.64 | -- | 4.55 | 4.73 | Flame detection |

| AFBR-S6PY0211 | 4.64 | 180 | -- | -- | Gas sensing |

| AFBR-S6PY0573 | 4.35 | -- | 4.05 | 4.65 | Flame detection |

| AFBR-S6PY1601 | 5 | -- | 5 | -- | Flame detection |

| AFBR-S6PY0574 | 4.55 | -- | 4.34 | 4.76 | Flame detection |

| AFBR-S6PY0575 | 3.91 | -- | 3.865 | 3.955 | Flame detection |

Thin film pyroelectric dual-channel sensors

| Broadcom part number | Filter center wavelength (µm) | Filter half power bandwidth (nm) | Cut on wavelength (µm) | Cut off wavelength (µm) | Application |

| AFBR-S6PY1943 | 3.91 (Reference) | 90 | -- | -- | Gas sensing |

| 4.3 (CO2 narrow) | 110 | -- | -- | Gas sensing | |

| AFBR-S6PY2486 | 3.91 (Reference) | 90 | -- | -- | Gas sensing |

| 3.33 (H-C) | 160 | -- | -- | Gas sensing | |

| AFBR-S6PY2572 | 4.9 (Reference) | 130 | -- | -- | Gas sensing |

| 4.26 (CO2 medical) | 180 | -- | -- | Gas sensing | |

| AFBR-S6PY0234 | 3.91 (Reference) | 90 | -- | -- | Gas sensing |

| 4.26 (CO2) | 180 | -- | -- | Gas sensing | |

| AFBR-S6PY3151 | 370 (Reference) | 110 | -- | -- | Gas sensing |

| 4.26 (CO2) | 180 | -- | -- | Gas sensing | |

| AFBR-S6PY2626 | 3.91 (Reference) | 90 | -- | -- | Gas sensing |

| 3.3 (CH4) | 160 | -- | -- | Gas sensing |

Table 1: Shown are key spectral characteristics of the Broadcom single and dual-channel thin film pyroelectric sensors. (Table source: Art Pini)

The wavelength limits of the optical filters used are specified by the center wavelength and either the half-power bandwidth of the filter or the cut-on and cutoff wavelengths of the bandpass filter. Dual-channel models, intended for gas analysis applications, are filtered to detect specific gases as well as an adjacent reference wavelength. For example, the dual-channel AFBR-S6PY0234 sensor has an analysis window filtered to 4.26 µm for CO2 detection and a reference window at a wavelength of 3.91 µm, which falls into the gap between the absorption peaks for CO and CH4 shown in Figure 1. It also has a fast time constant of 12 milliseconds (ms) for fast flame detection.

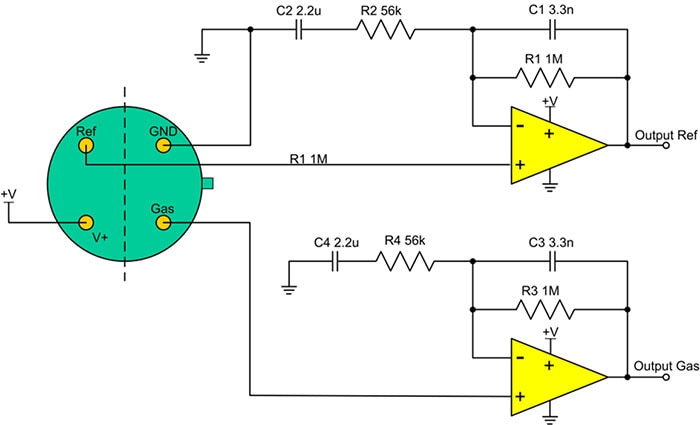

Interfacing the sensors is relatively easy; a simple non-inverting amplifier provides bandpass gain to provide adequate drive for the subsequent circuitry (Figure 5).

Figure 5 : Shown is a schematic diagram of a simple amplifier interface for a dual-channel thin film pyroelectric IR sensor. (Image source: Broadcom)

Figure 5 : Shown is a schematic diagram of a simple amplifier interface for a dual-channel thin film pyroelectric IR sensor. (Image source: Broadcom)

This amplifier provides 25 decibels (dB) of voltage gain to the AC component of the sensor output signal over a bandpass frequency range of 1 to 50 Hz. At DC (0 Hz), the amplifier is a unity gain voltage follower. Above 50 Hz, the output level decreases slowly back to unity gain.

Conclusion

If you’re looking for a gas sensing solution, Broadcom analog sensors are simple, low-component count devices in single-channel or dual-channel configurations. They feature high-performance specifications inherent in their thin film, pyroelectric PZT construction, including current mode sensing with 150 kV/W responsivity, stable response over the full flame flicker range of 3 to 15 Hz, a fast time constant of 12 ms for quick flame detection, and a high SNR of 10,000. Their high responsivity supports lower operating power levels for extended IR source life, making them ideal components for gas and flame detection systems.

Have questions or comments? Continue the conversation on TechForum, DigiKey's online community and technical resource.

Visit TechForum