Vybronics strong ERM cylindrical vibration motors are designed to deliver high-output vibration force for applications where power and durability are essential.

LadyADA EYE on NPI series reviews Vybronics Rectangular Linear Resonant Actuator Vibration Motor technology.

Adafruit Technologies discusses haptic feedback, applications, design, and usage of Vybronics offering of ERM and LRA vibration motors.

Rectangular LRA Vibration Motor

Publish Date: 2023-05-22

Rectangular LRA Vibration Motor

Publish Date: 2023-05-22

Vybronics' linear resonant actuators (LRA) generate vibration/haptic feedback in the plane parallel to the motor's largest surface.

Compression Spring Contact Vibration Motor Series

Publish Date: 2022-01-20

Compression Spring Contact Vibration Motor Series

Publish Date: 2022-01-20

Vybronics' motor series features a lower cost than SMD reflow types.

PCB Through-Hole Vibration Motor Series

Publish Date: 2022-01-20

PCB Through-Hole Vibration Motor Series

Publish Date: 2022-01-20

Vybronics' PCB vibration motor series is available with though-hole pin lengths of either 1.6 mm, 2.0 mm, or 3.2 mm.

Encapsulated Vibration Motor Series

Publish Date: 2019-05-02

Encapsulated Vibration Motor Series

Publish Date: 2019-05-02

Vybronics' encapsulated vibration motors are designed for applications that require the assembly to be potted, over-molded, or fully submerged in a liquid.

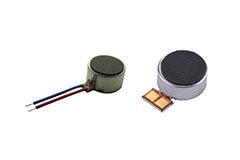

SMD/SMT Series Reflow Solderable Vibration Motors

Updated: 2019-04-23

SMD/SMT Series Reflow Solderable Vibration Motors

Updated: 2019-04-23

Vybronics' SMD/SMT series reflow solderable, vibration motors are available on tape and reel for use with pick and place machines.

Low Current Vibration Motor Series

Updated: 2020-07-13

Low Current Vibration Motor Series

Updated: 2020-07-13

The Z4TL2B03715452 is a member of Vybronics' low current/low power consumption motor series.

LRA Coin Vibration Motor

Updated: 2019-10-03

LRA Coin Vibration Motor

Updated: 2019-10-03

Vybronics' coin-sized linear resonant actuators (LRA) generate vibration and haptic feedback in the Z plane, perpendicular to the motor's surface.

DC Micro Motor Series

Publish Date: 2017-10-25

DC Micro Motor Series

Publish Date: 2017-10-25

Vybronics' DC micro motors are available in diameters ranging from 4 mm to 7 mm.

BLDC Brushless Coin Vibration Motors

Updated: 2019-10-03

BLDC Brushless Coin Vibration Motors

Updated: 2019-10-03

Vybronics' BLDC brushless coin vibration motors are recommended for applications requiring an exceptionally long life time/MTBF.

VL-Series Linear Vibration Motors

Publish Date: 2016-10-25

VL-Series Linear Vibration Motors

Publish Date: 2016-10-25

The Vybronics linear resonant actuators (LRA) vibration motors are an excellent choice for haptic applications.

Vybronics

Vybronics

Vybronics is one of the world’s largest manufacturers of micro vibration motors. Our product range includes cylindrical ERM, coin type and linear vibration motors ( LRA’s).

VC0720B Series Coin Vibration Motors

Publish Date: 2016-08-04

VC0720B Series Coin Vibration Motors

Publish Date: 2016-08-04

Vybronics' VC0720B001F coin vibration motor is 7 mm x 2.1 mm and was designed for devices requiring vibration alerts or haptic feedback.

Mid-Mount Coin Vibration Motors with Spring Contacts

Publish Date: 2016-08-04

Mid-Mount Coin Vibration Motors with Spring Contacts

Publish Date: 2016-08-04

Vybronics' C1020K001F coin vibration motor is 2.1 mm x 10 mm and is used to provide silent vibration alerts or haptic feedback to the user.

For efficient mass production, surface mounted components are almost always preferred to there leaded counterparts.

Design engineers seeking to use more than one vibration motor to achieve haptic effects or increased vibration energy should carefully consider the implications of doing so.

Due to their fast rise and fall times, linear vibration motors are an excellent choice for haptic feedback applications requiring a device with high reliability and exceptionally long life.