Use Intelligent Power-Device Switches to Counter Limitations of Simple Solutions

“Keep it simple” is a well-known design guideline and good engineering practice. After all, the more components you add, the more things can go wrong or cause unanticipated problems. And that’s in addition to the obvious impact on the bill of materials (BOM).

Nonetheless, every such guideline has plenty of legitimate exceptions. That’s especially true when you strive for a solid, “bulletproof” design that will work under normal and extreme circumstances, enduring foreseeable and unavoidable stresses. For additional integrity, you may also want to reduce your dependence on the system microcontroller unit (MCU) to handle disruptive events and instead rely on faster, more reliable, built-in hardware with minimal or no software.

Consider the MOSFET-based power switch, which is widely used in automotive and other applications to replace traditional electromechanical relays. Dozens of these solid-state switches provide simple on/off control for power rails supplying engine, transmission, lighting, braking, wiring, and suspension controls. These semiconductor switches have a life that exceeds one million cycles and, unlike electromechanical relays, are not susceptible to contact failure due to contact friction, aging, gases, or carbides in the harsh automotive environment.

It's conceptually straightforward to build a general-purpose on/off switch. However, these MOSFET-based switches can break down due to short circuits and transients that occur when switching high-energy circuits during start-up or regular operation. As a result, the switch must be surrounded with various protective energy-absorbing components to become a more sophisticated device. These extra components can be located external to the MOSFET switch or within its package, transforming it into a basic intelligent power device (IPD) switch (Figure 1).

Figure 1 : A simple MOSFET can function as a power switch (left) but lacks the energy-absorbing components (right) to protect it from the real world of unavoidable transients and short circuits. (Image source: ROHM Semiconductor, modified by Author)

Figure 1 : A simple MOSFET can function as a power switch (left) but lacks the energy-absorbing components (right) to protect it from the real world of unavoidable transients and short circuits. (Image source: ROHM Semiconductor, modified by Author)

Not the end of the story

There’s more to protection than using suitable components around the power switch. Nearly every current-carrying rail needs protection to prevent excessive current from damaging the power switch or its load circuit. These overcurrent situations are often the result of a fault within the load.

You might think the solution to overcurrent protection is easy and well-known: just install a basic, thermally-activated fuse in line with the supply rail. If there’s an overcurrent situation, the fuse will be activated and go to its open-circuit mode, thereby totally cutting off the flow of damaging current.

The fuse solution certainly works but, in some ways, it works too well. Once the fuse blows, the system MCU cannot obtain any insight into what is happening at the load module, nor can it manage it.

For this reason, many critical circuits also employ a current monitoring function. This allows the MCU to read an error signal detected by the overcurrent-detection IC and enables it to send signals to the IPD switch to initiate shutdown or repeated shutdown/restart cycling, depending on the nuances of the situation.

However, this can result in unstable circuit operation or other malfunctions. In contrast, advanced IPD switches in the AECQ-100 family from ROHM Semiconductor provide protection functionality without an intervening MCU. These automotive-qualified (AEC-Q100) devices are available as low-side or high-side switches in single and dual-channel configurations. They come in various 8-pin packages and support multiple voltage and current levels.

For example, the BD1HD500FVM-CTR is a single-channel, high-side switch with an on resistance (RDS(ON)) of 500 milliohms (mΩ) and a current limit of 1.45 amperes (A) in an 8-lead MSOP package. In contrast, the single-channel BV1LB025EFJ-CE2 is a low-side switch with an RDS(ON) of 45 mΩ and a current limit of 13 A in an HSSOP-C16 package.

The AECQ-100 family of IPD switches can supply a minimum current level during protection operation, so the circuit continues to operate (if possible) while generating an error signal. This makes it possible to make emergency “calls” during circuit operation in the event of non-fatal abnormalities.

Further, these advanced IPD switches prevent circuit blackouts. These can occur if the mechanical load increases due to aging, resulting in increased current draw levels. By enabling independent operation without going through an MCU, the number of components required for this functionality is reduced while reliability is enhanced (Figure 2).

Figure 2 : Shutdown is the only option when using a standard IPD switch. However, a ROHM IPD switch supports both protection against inrush currents and steady-state operation after inrush protection has been accomplished. (Image source: ROHM Semiconductor)

Figure 2 : Shutdown is the only option when using a standard IPD switch. However, a ROHM IPD switch supports both protection against inrush currents and steady-state operation after inrush protection has been accomplished. (Image source: ROHM Semiconductor)

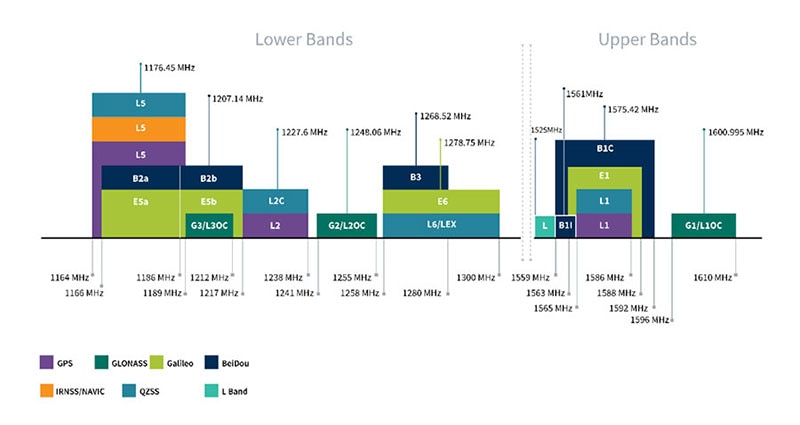

There’s another consideration with fuses. Standard fuses with well-defined operating margins prevent inadvertent cutoff due to higher inrush current during the system or module’s power-on phase (Figure 3, top). However, this cushion or “masking” interferes with the desired limit setting.

In contrast, ROHM’s IPD switches can protect against inrush current and eliminate the need for masking. (Figure 3, bottom).

Figure 3 : A conventional thermal fuse has an ambiguity region that masks and discourages inadvertent activation due to inrush currents (top), while the ROHM IPD switch has more sophisticated thresholds and limits (bottom). (Image source: ROHM Semiconductor)

Figure 3 : A conventional thermal fuse has an ambiguity region that masks and discourages inadvertent activation due to inrush currents (top), while the ROHM IPD switch has more sophisticated thresholds and limits (bottom). (Image source: ROHM Semiconductor)

The result is high-accuracy detection of even minor current abnormalities during steady-state operation. At the same time, since a minimum current can still be supplied to the load module instead of shutting down its operation immediately after an abnormality occurs, a system MCU can still attempt to access that module for preventive maintenance while detecting abnormalities during operation.

Looking at the big picture

Using power devices supplemented by various protective components and functionality is a necessary but insufficient step to implementing effective power-rail management, especially in harsh automotive settings. Additional protection and flexibility are needed in overcurrent situations.

Conclusion

Simplicity in design is a worthy goal, but real-world considerations and subtleties often mean that a little additional sophistication is a prudent and better approach in practice. By using IPD switches from ROHM’s AECQ-100 family, you can get the reliability, flexibility, and benefits of a solid-state power device with fewer components while achieving insight and protection that fuses cannot offer.

Related Content

IPD Automotive Switches with Nick Ikuta

https://www.digikey.com/en/videos/r/rohm-semiconductor/ipd-automotive-switches-with-nick-ikuta

Training Module/Tutorial: Intelligent Power Device (IPD) Switches

https://www.digikey.com/en/ptm/r/rohm-semiconductor/ipd-switches/tutorial

Have questions or comments? Continue the conversation on TechForum, DigiKey's online community and technical resource.

Visit TechForum