Get Comfortable with eFuses: They Have Many Useful Features

There’s something very tangible and satisfying about the traditional thermal fuse. It does one thing – namely, permanently cut the flow of current to zero when an overcurrent fault condition occurs – does it well, does it reliably, and induces no headaches while it stays silently on guard duty. It can also be checked visually or easily with an ohmmeter (Figure 1).

Figure 1: The status of conventional thermal fuse is easy to check; it can often be done visually but if it can’t be done that way, an ohmmeter can be used for a simple, unambiguous continuity test. (Image source: Wololo.net)

Figure 1: The status of conventional thermal fuse is easy to check; it can often be done visually but if it can’t be done that way, an ohmmeter can be used for a simple, unambiguous continuity test. (Image source: Wololo.net)

Countless billions are in daily use, as a first or final line of defense against various failures which might do anything from damage downstream components to starting a fire. Perhaps we also like these fusible-link devices because they provide a primal connection: heating and melting, giving us a link back to our caveman days. Or perhaps we like their sense of nobility as they selflessly sacrifice themselves to save the source or load from damage.

Whatever the reason, the reality is that times change, technologies advance, and applications change. Thus, even the classic thermal fuse cannot offer all of the fuse-related functions and features needed to satisfy the needs of modern designs. The electronic fuse, written as eFuse or e-Fuse, is quickly gaining a large role in protecting subcircuits and functions due to its unique capabilities which are unavailable in the classic thermal fuse. But using it requires a shift in fusing “mindset” on the part of the designer in many cases.

What’s an eFuse?

Although thermal and eFuses both contain the word “fuse,” their operating principles are dramatically different. The principle of the thermal fuse is direct: current heats its fusible link via I2R dissipation and melts it if that current gets too large. The speed of this melting action and opening of the current path depends on how much excess current flows and for how long.

In the eFuse, current to the load passes through a FET while a dedicated current sensor measures that current by monitoring the voltage across a sense resistor. When the sensed voltage exceeds a threshold limit, the FET is turned off and the current flow stops (except for any FET leakage current).

As a consequence of these very different operating principles, the thermal fuse and the eFuse also have very different characteristics. Depending on the application, the eFuse attributes may be a benefit or a drawback. These include:

- Very fast short-circuit protection: the ultra-high-speed short-circuit protection technique provides a basic fusing role in milliseconds or even microseconds, much faster than a thermal fuse.

- The overcurrent protection value is fairly accurate, and depending on the eFuse, is user-set via external resistors or factory set; this is more precise than thermal fuses which rely (to a first order) on a combination of current and time.

- Unlike a basic fusible-link device, the standard eFuse can automatically re-establish current flow after the overload subsides.

- An eFuse can also prevent excessive voltage from being applied to the load by clamping the outputs for instantaneous voltage increases.

- Some eFuses can suppress inrush current via an added external capacitor which sets the turn-on slew-rate at the desired value.

These features and characteristics make the eFuse a good match for applications such as hot-swap controllers or automobile subcircuits, where there is a brief, potentially damaging, current or voltage transient spike which must be suppressed immediately, yet current flow can resume once the transient has subsided.

You could build your own eFuse from the basic components, and that has been done. Yet as is often the case, an IC version offers improved, consistent performance in a smaller package, while also adding features that would be difficult to provide in a DIY discrete version. While a basic eFuse needs only a few components in principle, in practice a complete and more functional eFuse circuit may also need diodes and transient voltage suppression (TVS) devices plus some resistors and capacitors.

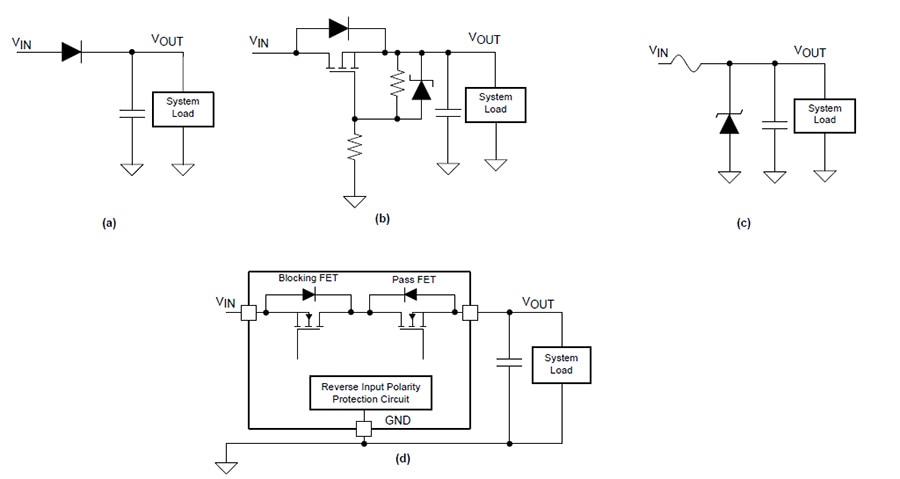

For example, adding the common and very useful feature of reverse voltage protection can be done in several ways: via an added diode (with its undesired forward diode drop); an ideal diode circuit with a P-MOSFET; or a thermal fuse plus TVS diode (Figure 2). Instead, a solution with fewer design issues and better, fully characterized performance, is the TPS26620 from Texas Instruments. It’s also a smaller solution than a discrete version, measuring just 3 × 3 millimeters (mm).

Figure 2: A discrete eFuse can be implemented in several ways, using a: a) diode; (b) P-MOSFET; (c) thermal fuse plus TVS Diode; or (d) TPS26620 eFuse. (Image source: Texas Instruments)

Figure 2: A discrete eFuse can be implemented in several ways, using a: a) diode; (b) P-MOSFET; (c) thermal fuse plus TVS Diode; or (d) TPS26620 eFuse. (Image source: Texas Instruments)

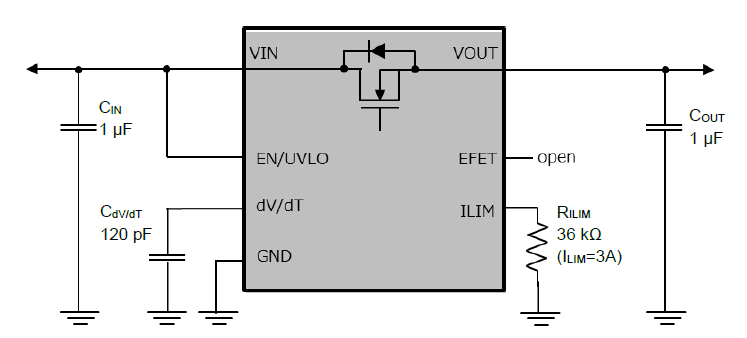

There’s another strong reason to be very cautious when going the DIY eFuse route: formal certification. All thermal fuses meet the regulatory standards for protection and thus, ease product approval. However, a self-constructed eFuse will not inherently meet these requirements, including, but not limited to, creepage and clearance (which are functions of voltage). As a result, they must be independently certified. This certification is a major commitment and effort which can be avoided by using one of the many certified eFuses. For example, the recently announced TCKE805NL 5 ampere (A) eFuse from Toshiba Semiconductor and Storage Corp. is certified to IEC62368-1, the fairly new hazard-based product safety standard for information and communication technology (ICT) and audio/video equipment (Figure 3).

Figure 3: The Toshiba TCKE805NL meets the relatively new IEC62368-1 hazard-based product safety standard for ICT and AV equipment. (Image source: Toshiba Semiconductor and Storage)

Figure 3: The Toshiba TCKE805NL meets the relatively new IEC62368-1 hazard-based product safety standard for ICT and AV equipment. (Image source: Toshiba Semiconductor and Storage)

Conclusion

It’s unrealistic to think that eFuses will completely replace the widely used thermal-link fuses. The reality is that each type has distinct features and benefits, and a clear role to play in modern circuit and system design. For many designers, the best option is to use both. eFuses can be used locally, while the thermal fuse can be used as a backstop for larger system functions where current levels and voltages are higher and there are circuit or safety dangers from excessive current flow.

However, using eFuses alone or in combination with thermal fuses requires a change in mindset when considering fusing options. Beyond the basic specification for current limit value for both fuse types, the parameters for assessing eFuses are quite different than those for thermal fuses and must be judged in that context. When used together, thermal fuses and eFuses make a powerful pairing of functions, features, flexibility, and certainty.

Further Reading:

“The Right Power Supply is Critical to Meet the New IEC/UL IEC-62368 Consumer Product Safety Mandate”

“Fuse Tutorial”

https://www.digikey.com/en/articles/fuse-tutorial

External References

Texas Instruments, SLVA862A, “Basics of eFuses”

http://www.ti.com/lit/pdf/slva862

Texas Instruments, “eFuse and hot swap controllers”

http://www.ti.com/power-management/power-switches/efuse-hotswap-controllers/overview.html

CUI Devices, “IEC 62368-1: An Introduction to the New Safety Standard for ICT and AV Equipment”

TUV, “What You Need to Know about IEC 62368-1”

https://insights.tuv.com/blog/what-you-need-to-know-about-iec62368-1

Optimum Design Associates, “Clearance and Creepage Rules for PCB Assembly”

http://blog.optimumdesign.com/clearance-and-creepage-rules-for-pcb-assembly

Have questions or comments? Continue the conversation on TechForum, DigiKey's online community and technical resource.

Visit TechForum