The Right EV Charging Cable Provides User Comfort While Ensuring Safety and Reliability

The average person is very comfortable plugging and unplugging small and medium-sized electrical connectors. They don’t hesitate to do so with unprotected USB, RF coaxial, HDMI, and other small, low-voltage connectors for their phones and myriad other devices. They also have used those fully-exposed “barrel” connectors in conjunction with AC-DC adapters (wall warts) to charge devices. As these are all low-voltage, low-power connectors, there is no danger to the user.

Even with higher voltages, most consumers have no problem plugging in AC line cords (120/240 volts) as needed, and doing that is a less-frequent occurrence than it is with lower-voltage connectors. People have learned to use reasonable care with these AC connectors, as they are not fully enclosed, have somewhat exposed plug blades, and often have old, cracked insulation and connector bodies.

It is actually surprising how few fatalities and injuries there are from line shock. According to a report from the National Library of Medicine/National Institutes of Health (Electrical Injuries)1, there are approximately 1000 deaths per year as a result of electrical injuries in the United States. Of these, approximately 400 are due to high-voltage electrical injuries, while lightning causes 50 to 300. There are also at least 30,000 shock incidents per year that are non-fatal, and approximately 5% of all burn-unit admissions in the United States occur as a result of electrical injuries.

Approximately 20% of all electrical injuries occur in children, including toddlers and adolescents, and most of these occur at home. In adults, these injuries occur mostly in occupational settings and are the fourth leading cause of workplace-related traumatic death. The good news is that “at home” shocks, with burns and worse, are fairly rare. In short: people know that AC line voltages are potentially dangerous, and thus use reasonable caution when handling AC line cords and plugs. This familiarity and associated safety needs to become a part of the electric vehicle (EV) user experience.

EV charging raises familiarity and safety concerns

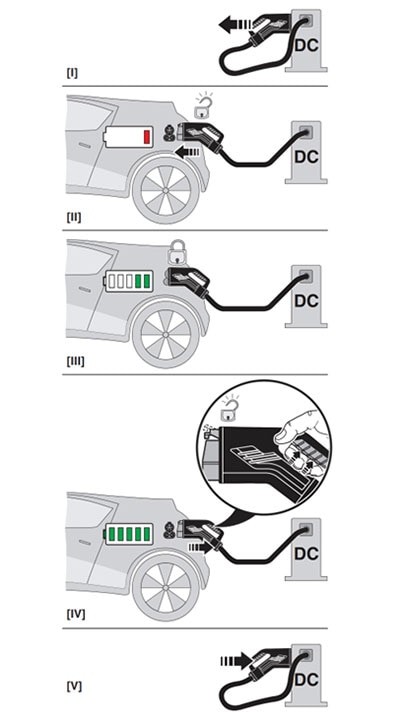

With the wider use of EVs, average consumers are expected to be comfortable with a higher level of voltage, current, and power (up to 250 kilowatts (kW)), along with the associated connectors and cable assemblies. While some EV users plan to charge “overnight at home” using a 120/240 volt AC (VAC) line, many will also install higher power Level 2 DC chargers at home to take advantage of their much faster charge time and higher efficiency. Users will undoubtedly also use Level 2 chargers on the road at public charging stations. These users expect the connect/disconnect process to be simple and reliable, with a refueling sequence similar to that of gas and diesel for internal combustion engines (ICEs) (Figure 1).

Figure 1: Part of establishing an EV comfort factor for users is ensuring that the connection and disconnection sequence for charging resembles that of the typical ICE vehicles (Image source: Phoenix Contact)

Figure 1: Part of establishing an EV comfort factor for users is ensuring that the connection and disconnection sequence for charging resembles that of the typical ICE vehicles (Image source: Phoenix Contact)

These chargers require a cabling and connector arrangement that must meet challenging objectives related to simplicity of use, close similarity with the gas/diesel form factor, significant electrical capacity, electrical and thermal safety, and overall ruggedness, including resistance to abuse.

It’s worth noting that the industry actually uses the term “cable” to refer to the connector and its cable, as the two are provided as a single, seamlessly integrated unit, not as two distinct subassemblies.

Connector plus cable example illustrates the challenge

AC line connectors and cables must meet modest electrical and mechanical requirements. These range from simple two-wire ungrounded arrangements, such as those used with residential table lamps, to three-wire, high-integrity grounded plugs for appliances. These come with solid molded cables and connector housings.

In contrast, EV arrangements must handle much higher currents and voltages, sense internal temperature rise due to ambient conditions and self-heating, take use and abuse from users (dropped on the ground, run over, left in a puddle of water and mud), and still provide extreme levels of electrical and mechanical integrity in an unprotected setting. Among the various scenarios, users may try (and succeed) at charging while the vehicle is partially in water (Figure 2).

Figure 2: Not recommended, but it still works: EV charging stations have multiple levels of protection to ensure safe charging even under very wet conditions. (Image source: Sun/News Group Newspapers/UK)

Figure 2: Not recommended, but it still works: EV charging stations have multiple levels of protection to ensure safe charging even under very wet conditions. (Image source: Sun/News Group Newspapers/UK)

It’s not easy to do all this, but it can be done, as shown by the family of CCS C-Line DC Charging Cables (including connectors) for electric vehicles from Phoenix Contact. The family consists of two similar groups, but with a distinct difference: there’s Type 1 for North America (SAE J1772) with a discrete locking clip, and Type 2 for Europe (IEC 62196-3) (Figure 3). These two groups have slightly different specifications and physical appearances.

Figure 3: The CCS C-Line DC charging connectors for North America (left) and Europe (right) provide similar functionality but in slightly different form factors. (Image source: Phoenix Contact)

Figure 3: The CCS C-Line DC charging connectors for North America (left) and Europe (right) provide similar functionality but in slightly different form factors. (Image source: Phoenix Contact)

The CCS C-Line DC charge cables are equipped with a unique, lightweight connector that is designed to CCS standards, but comes in a smaller form factor for easier handling and storage. These cables were created for use in locations where high charge power is not needed and where DC charging is preferred over AC. They will be used in personal residences, apartment complexes, parking facilities, and businesses. With charge currents up to 80 amperes (A), CCS C-Line cables offer higher level capability and reduced charge time compared to AC charge cables.

The primary market will be for manufacturers of EV service equipment (EVSE) and vehicle fleet operators. Within both the Type 1 and Type 2 groups, there are different offerings with a choice between either 6 AWG or 10 AWG wires depending on the current capacities involved, and cable lengths ranging from 4 to 7 meters (m).

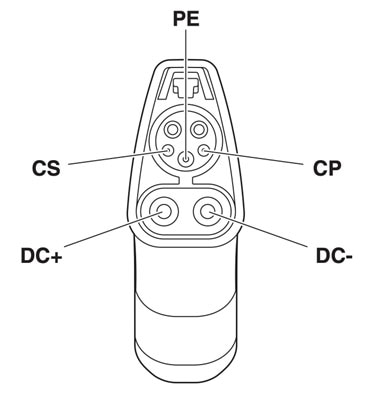

Users don’t care about the schematic or functional assignments of the contacts of the connector, such as the plus and minus DC power contacts (DC+ and DC-), protective earth (PE), and post-insertion signal contacts (CS and CP) (Figure 4).

Figure 4: The critical contacts of the CCS C-Line connector are the plus and minus DC power contacts (DC+ and DC-), protective earth (PE), and post-insertion signal contacts (CS and CP). (Image source: Phoenix Contact)

Figure 4: The critical contacts of the CCS C-Line connector are the plus and minus DC power contacts (DC+ and DC-), protective earth (PE), and post-insertion signal contacts (CS and CP). (Image source: Phoenix Contact)

Instead, what they do care about is a comforting form factor with a look and feel that is familiar and reminiscent of the traditional “pistol-grip” gas/diesel pump handle assembly (Figure 5).

Figure 5: In use, the DC assembly using the CCS charging arrangement has the reassuring familiarity of a gas/diesel tank refueling process. (Image source: Phoenix Contact)

Figure 5: In use, the DC assembly using the CCS charging arrangement has the reassuring familiarity of a gas/diesel tank refueling process. (Image source: Phoenix Contact)

However, the many technical features needed for successful CCS EV charging must be invisible or transparent to the users; these features are keyed to the circled numbers in Figure 6.

Figure 6: The CCS C-Line includes six key technical and performance features and functions that the user may not notice (unless there’s a label and a logo), but which are critical to proper, effective, reliable, and safe operation. (Image source: Phoenix Contact, modified by Bill Schweber)

Figure 6: The CCS C-Line includes six key technical and performance features and functions that the user may not notice (unless there’s a label and a logo), but which are critical to proper, effective, reliable, and safe operation. (Image source: Phoenix Contact, modified by Bill Schweber)

1) Integrated temperature sensor technology: With precise temperature measurement directly at the power contacts, the charging process can be interrupted in the event of overheating to protect the user from danger and the charging station from damage.

2) Silver-plated contacts: The silver-plated surfaces of the power and signal contacts ensure efficient power transmission, optimum corrosion protection, and long service life.

3) An individual logo: As an alternative to the Phoenix Contact logo, the charging connectors can be supplied with a custom logo printed on a UV and weather-resistant plastic label.

4) Compact design with ergonomic handle: The ergonomic shape of the gripping zone guarantees easy handling and ensures a comfortable feel. In addition, the compact design ensures the charging station and charging connector have a harmonious overall appearance.

5) Clever sealing concept: The sophisticated sealing concept ensures continuous longitudinal water tightness, preventing moisture from penetrating the charging connector or the cable.

6) Cable designed in accordance with DIN EN 50620: The particularly robust, VDE-certified charging cable has been specially designed for use in e-mobility applications with respect to insulation thickness, material flexibility, and other properties.

Conclusion

The DC charging of EVs requires a connector and cable assembly that satisfies stringent electrical and mechanical performance criteria. At the same time, it must have a look, feel, action, and overall comfort factor that works for consumers. The Type 1 and Type 2 CCS C-Line DC Charging Cables from Phoenix Contact satisfy these requirements, and are available in multiple versions to meet different end-design requirements.

Related Content

1: Compact CCS Cables Provide Level 2 Fast DC Charging

https://www.digikey.com/en/articles/compact-ccs-cables-provide-level-2-fast-dc-charging

2: How to Employ a Range of Connectors to Support Comprehensive EV Charging Infrastructure

https://www.digikey.com/en/articles/how-to-employ-a-connectors-for-ev-charging-infrastructure

References

Have questions or comments? Continue the conversation on TechForum, DigiKey's online community and technical resource.

Visit TechForum