The New INA228 Digital Power Monitor Lets My BattLab-One Measure Down to Nanoamps

At the time of writing this blog, the current sensing range of the power profiling device I use, the BattLab-One, is from 10 microamps (µA) to 500 milliamps (mA). While this range provides good coverage for many microprocessors, newer ultra-low-power microprocessors are operating in the nanoamp (nA) range during sleep mode. Measuring current in the nanoamp range with a digital power-monitoring solution has proven difficult.

The BattLab-One is based on Texas Instruments’ (TI) INA233. This dedicated current sense device measures current, bus voltage (much higher than the supply rails), power, and sends sample data over I2C (or SPI).

I chose the INA233 for several reasons, including its maximum 10 microvolts (µV) of offset voltage, 16-bit analog-to-digital converter (ADC), programmable sample averaging and sample rates, and its I2C communication capability. Unfortunately, the 8 µA bias current of the INA233 limits my current-sensing capability in the lower range to 10 µA. While I have been able to calibrate out much of the bias-current error, the 8 µA limits my ability to capture sleep modes on the latest ultra-low-power microprocessors operating in the nanoamp range.

Fortunately for me, TI has a new addition to its digital power monitoring lineup, the INA228 (Figure 1). The INA228 is pin-compatible with the INA233 and offers a much-improved maximum 2.5 nA of input bias current. Yes, only 2.5 nA of input bias current! That translates to just a potential maximum 2.5% error when measuring a 100 nA sleep current!

Figure 1: The Texas Instruments INA228 has a maximum input bias current of 2.5 nA, compared to the INA233’s 8 µA, and it’s also moved up to a 20-bit ADC instead of 16. (Image source: Texas Instruments)

Figure 1: The Texas Instruments INA228 has a maximum input bias current of 2.5 nA, compared to the INA233’s 8 µA, and it’s also moved up to a 20-bit ADC instead of 16. (Image source: Texas Instruments)

The INA228 has also upgraded to a 20-bit ADC and includes the same I2C (and a SPI version) communication as the INA233. In addition, the INA228 has lowered the offset voltage to a maximum of 1 µV.

Another great feature of the power monitor solutions from Texas instruments is the separation of the supply rail voltage and the common-mode voltage inputs for the ADC. Additionally, for the INA228, the input to the ADC can range from plus/minus 40.96 millivolts (mV) with a programmable range of up to plus/minus 163.84 mV. This has the added benefit of being able to use smaller sense resistors which in turn lowers the voltage drop associated with current sensing.

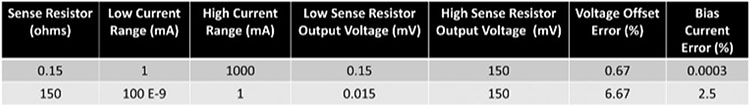

The INA228 has enabled me to extend the range of the current sensing I use all the way down to 100 nA and keep a maximum total error due to input-bias-current-plus-offset voltage to less than 10%. Table 1 shows the INA228-enabled design parameters for the new BattLab-One+ product.

Table 1: Design parameters for the new BattLab-One+ product showing, among other features, the high current range and low bias error. (Image source: Doug Peters)

Table 1: Design parameters for the new BattLab-One+ product showing, among other features, the high current range and low bias error. (Image source: Doug Peters)

There’s no free lunch

So, everything is going great in my world, right? All I have to do is swap out the INA233 with the INA228, and all of my troubles are solved! Not so fast. Remember I mentioned that the INA233 is a 16-bit ADC and the INA228 is 20 bit? You guessed it; all the firmware is based on 2 bytes of data per sample from the INA233. The INA228 uses 3 bytes. Not a huge impact, but it means existing users will need both the new INA228 and a firmware update to get the higher bandwidth current sensing range (or they can just buy the new BattLab-One+ when it is released in a few months!)

I guess it’s true what they say, there is no free lunch.

Conclusion

There’s no question about it, designing with Texas Instruments’ digital current sensing products has made life a lot simpler. As outlined here, it has enabled a natural improvement of the BattLab-One as TI improves its power-monitoring solutions. In this case from the INA233 to the INA228.

Have questions or comments? Continue the conversation on TechForum, DigiKey's online community and technical resource.

Visit TechForum