Protect Your Test Equipment Using Digital Isolators

On more than one occasion, I’ve had an unfortunate run-in with prototype circuitry that malfunctioned. This is relatively common, but on several occasions, I’ve had expensive test equipment connected to the circuitry which also went up in smoke! Obviously, we need to protect our tools and test equipment from unproven circuitry, and a great way to do that is through isolation.

The first time I encountered an issue with damaged equipment something had gone terribly wrong with the system I was monitoring and too much voltage or current found its way from the circuit, through my USB-to-USART converter, and into the USB port on my computer. A damaged computer is a great way to make you stop and ask, “What could I have done to protect my computer?”

For a USART, the answer was quite simple and quite inexpensive. I had been using a break-out board from SparkFun that was very similar to the DEV-09873 USB bridge module, and all I needed to do was place an STMicroelectronics STISO621WTR dual-channel digital isolator between the embedded systems’ Tx/Rx lines and the Tx/Rx lines on the USB bridge (Figure 1). For literally under $20, including a few connectors and prototype board, and 10 minutes of soldering, I could have saved several thousand dollars of equipment!

Figure 1: The STMicroelectronics STISO621WTR dual-channel digital isolator protects two, unidirectional communication channels and could have saved my equipment. (Image source: STMicroelectronics)

Figure 1: The STMicroelectronics STISO621WTR dual-channel digital isolator protects two, unidirectional communication channels and could have saved my equipment. (Image source: STMicroelectronics)

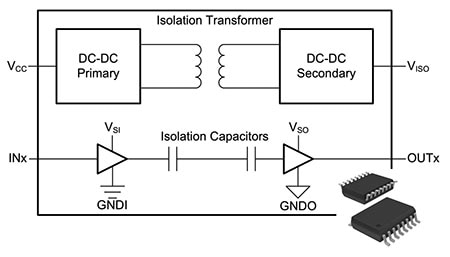

What’s interesting about the STISO621WTR is that it is already set up in a configuration that lends itself to protecting a USART. Figure 1 shows how the two channels are set up for communication in opposite directions which eases layout or wiring issues. The isolator provides 6 kilovolts (kV) of galvanic isolation and over 50 kV per microsecond (kV/µs) common-mode transient protection. The fact that the isolator can also handle data rates up to 100 megabits per second (Mbits/s) means it can even be used in high-speed applications.

Another area that I have often found can use some additional isolation is on the input of logic analyzers. Logic analyzers can cost several hundred to several thousand dollars, and sometimes don’t have very good isolation on their inputs. Unfortunately, I once damaged a logic analyzer I had for over a decade because the circuit input protection only went up to 10 volts, and I accidentally one groggy morning connected it to a 12 volt signal. The device didn’t go up in smoke, but my wallet did for the replacement unit!

Developers can quite easily protect the inputs on their logic analyzers by again using some digital isolation. To protect test equipment, it’s often a little less convenient because the isolators do require an external power supply. This often requires a few extra jumpers from the test circuitry and also from another source in order to power both sides of the isolator. For a communication interface this still needs to be done, but the power and grounds are usually right there anyways.

One isolator that I’ve used to protect my test equipment is Texas Instruments’ ISOW7844DWE four-channel, general-purpose digital isolator (Figure 2). This isolator can support data rates up to 100 Mbits/s, which is important if you are connecting to test equipment. It wouldn’t make much sense to put a 2 Mbit/s digital isolator on the front end of a 10 Mbit/s logic analyzer. That brings me to another important point, if you do plan to add isolation to your test equipment, make sure that it doesn’t adversely affect the measurement system: it’s possible to inject new artifacts or issues, so be careful.

Figure 2: Data rates are important for digital isolators used to protect instruments, and the ISOW7844DWE can support up to 100 Mbits/s. (Image source: Texas Instruments)

Figure 2: Data rates are important for digital isolators used to protect instruments, and the ISOW7844DWE can support up to 100 Mbits/s. (Image source: Texas Instruments)

There are quite a few digital isolators available for nearly every application imaginable, and it’s quite easy to search through and find an isolator that fits yours. When looking to protect my equipment, I will often also cross-reference the isolator’s footprint to make sure that I can get a breakout board so that I can quickly prototype a solution. In some instances, like to protect the logic analyzer, I get a little more complex and build out my own isolation board.

Conclusion

Test equipment and tools are typically expensive and important assets. Many developers only have one, which means we need to account for Murphy’s Law striking our test equipment at the worst possible moment. So, don’t be me: use digital isolation. Just be careful that the isolation doesn’t affect the measurement system itself. Once that protection is in place, you can relax, a bit: the chance that faulty circuity or a lapse in attention will damage your equipment has been dramatically reduced.

Have questions or comments? Continue the conversation on TechForum, DigiKey's online community and technical resource.

Visit TechForum