Lining Up Connectors for the Growing Demands of Electronics Miniaturization

Miniaturization has become a critical engineering concern in virtually any manufacturing scenario involving electronics. Today’s design engineers are progressively packing more performance into existing or smaller form factors to maximize performance within constrained spaces.

While performance maximization can vary across markets, it typically involves a combination of faster communication, higher data throughput, safer functionality, and improved user experience.

For instance, consumers seek lightweight yet responsive mobile devices that are convenient to carry anywhere. Automakers designing electric vehicles (EVs) must optimize overall weight to achieve maximum mileage from every charge. Patients requiring wearable medical devices need low-profile yet durable convenience without compromising connected functionality.

Connected functionality is a key consideration in every use case. All electrical connector types, from power to signal, facilitate efficient data exchange within a system or device. If connectors cannot sufficiently shrink while accommodating increased functionality, there’s no way to achieve smaller and more efficient designs. Notably, a connector’s pitch significantly influences mechanical size; for miniaturized designs, the pitch must decrease while still supporting higher densities that meet the ever-evolving speed and performance demands.

Moreover, designing the appropriate type of connector for a specific application can have significant impacts on form factor and overall performance. A comprehensive range of factors impact smaller interconnects, including the need for multipurpose functionality, adaptability, signal integrity shielding, thermal management, and capacity optimization.

Addressing assembly concerns

Beyond manufacturing, other connectivity challenges exist that need to be overcome when working with more streamlined components. These challenges include:

- Assembly issues: Ultra-compact connectors can be challenging for humans to assemble due to their small size, often comparable to a single grain of rice. This makes it difficult to gauge mating force and visualize layout geometries on printed circuit boards (PCBs). Even slightly larger connectors may be positioned in such a way that they are hard to see, increasing the risk of misalignment, which could lead to safety or performance issues.

- Preserving performance: Smaller connectors are also more fragile and prone to breaking easily if not handled with care. This makes assembly more complex and time-consuming, whether done manually or using machines. Exertion when pressing connectors together needs to be carefully calibrated to avoid damaging pins and incurring additional costs.

- High-volume production: When factory line workers are required to handle thousands of connectors daily, the challenges mentioned above can become exponentially more significant. Repetitive motion at high volumes can lead to assembly mistakes and even musculoskeletal issues that can hinder productivity. In fact, studies have revealed that assembly-related repetitive motion injuries cost employers billions of dollars annually.

Addressing various needs

Many industries and applications are impacted by miniaturization, and no “one size fits all” connector can possibly address every need. So, designers need access to a wide range of connector options to support the specific needs of their applications.

Accommodating a wide range of design needs, Molex offers a comprehensive portfolio of miniaturized and micro-connectors, including the following:

Micro-Fit Connectors: These compact connection solutions can withstand operating temperatures up to 125°C and deliver power in wire-to-wire and wire-to-board configurations. They feature a 3.00 mm pitch and are available in multiple circuit sizes and cable lengths. An optional terminal position assurance (TPA) feature—such as with the Micro-Fit 1451320303 (Figure 1)—helps reduce the odds of terminal back-out, and the low mating force (LMF) design supports ergonomics.

Figure 1: A Molex Micro-Fit 1451320303 incorporates a terminal position assurance feature to reduce terminal back-out risks. (Image source: Molex)

Figure 1: A Molex Micro-Fit 1451320303 incorporates a terminal position assurance feature to reduce terminal back-out risks. (Image source: Molex)

- Nano-Fit Connectors: Available in wire-to-board and wire-to-wire configurations, these versatile power connectors feature a 2.50 mm pitch, fully protected header terminals, color-coding and keying options that support proper mating, and TPA.

- HDMI Connectors: When available real estate is a concern, these connectivity solutions help enhance speed and adaptability in a smaller footprint.

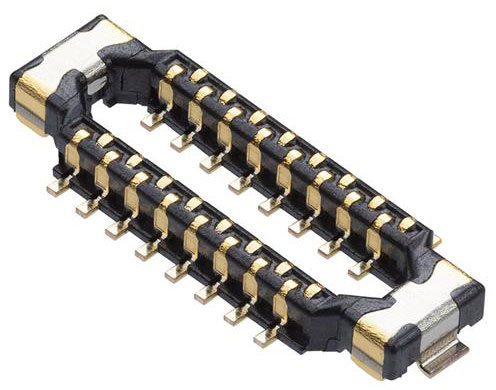

- Quad-Row Connectors: Ideal for space-constrained smartphones, smartwatches, virtual reality devices, and more, these feature a staggered circuit layout as with the Quad-Row 2033900323 (Figure 2), which positions pins across four rows at a signal contact pitch of just 0.175 mm.

Figure 2: The Molex Quad-Row 2033900323 32-position connector features a staggered circuit layout for space-constrained applications. (Image source: Molex)

Figure 2: The Molex Quad-Row 2033900323 32-position connector features a staggered circuit layout for space-constrained applications. (Image source: Molex)

- Easy-On Flat Flexible Cable (FFC) Connectors and Flexible Printed Circuit (FPC) Connectors: Available with an extensive combination of actuators, pitch sizes, and circuit sizes, these provide reliable, robust connectivity and design flexibility when space is at a premium. For instance, the ultra-compact LA75 Series FPC connectors offer a 0.30 mm pitch and are ideal for tight packaging needs.

- Mini50 Connectors: Available in sealed or unsealed single and dual-row receptacles, these are designed to accommodate more low-current electrical circuits in interior transportation vehicle environments. Automotive engineers reportedly achieve 50% space savings over traditional USCAR 0.64 mm connectors.

- SlimStack Connectors: Fine-pitch, low-profile board-to-board connectors engineered for space-constrained applications across an array of markets. They are available in various pitch options and stacking heights to help optimize adaptability.

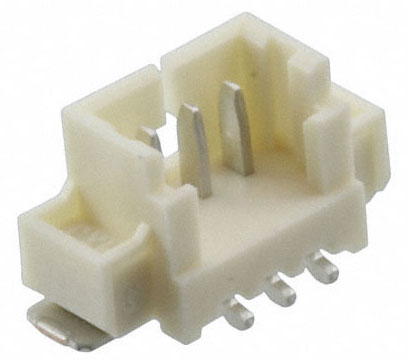

- PicoBlade Connector System: Featuring a 1.25 mm pitch, these versatile connectors—like the PicoBlade 0533980367 PCB header (Figure 3)—are suitable for a variety of applications and are commonly used across consumer electronics, automotive, and industrial markets.

Figure 3: The PicoBlade Series 53398 PCB headers feature a 1.25 mm pitch. (Image source: Molex)

Figure 3: The PicoBlade Series 53398 PCB headers feature a 1.25 mm pitch. (Image source: Molex)

- Pico-Clasp Connectors: These connectors are suited for wire-to-board applications and secure mating, providing a pitch of 1.00 mm and available in several circuit sizes.

- Micro-Clasp Connectors: These compact wire-to-board connectors, with a 2.00 mm pitch, feature a dual contact design for reliable connectivity.

- CLIK-Mate Connectors: Engineered for applications that require a compact form factor with higher pin counts, these wire-to-board connectors offer a positive lock design and an array of circuit sizes.

Conclusion

Miniaturization in electronics manufacturing requires ever-smaller connectors that can handle increased functionality. Molex offers a range of miniaturized connectors that help designers achieve their goals and overcome the performance and assembly challenges of smaller form factors for various applications across multiple industries.

Have questions or comments? Continue the conversation on TechForum, DigiKey's online community and technical resource.

Visit TechForum