In a Tight Spot? Utilize the World’s Smallest Board-to-Board Connectors in Your Design

Smartphones, wearable devices, Internet of Things (IoT) designs, and smart home devices are getting smaller and more capable, and the market is demanding still more features within them. This leaves us, the designers, with the problem of shrinking designs in order to add new functions. One of the many questions that pop up is how do we shrink board-to-board connectors without compromising reliability?

To help answer this, Molex worked with device designers, flexible printed circuit suppliers, and their own contractors, and came up with a unique approach, the Quad-Row Board-to-Board connectors. These, it seems, are the world’s smallest board-to-board connector family, ready-made for your next space-constrained design.

What makes Quad-Row different?

The laws of physics haven’t changed: the only way to reduce the size of a connector is to squeeze the contacts closer together. The limit here is that if contact spacing shrinks below the industry standard soldering pitch of 0.35 millimeters (mm), it will require special handling during manufacturing. That’s not an option for the high-volume manufacturers of consumer devices. Molex, already a leader in connectivity innovation, set its resources on the problem and came up with a series of high-density, quad-row, board-to-board connectors (Figure 1).

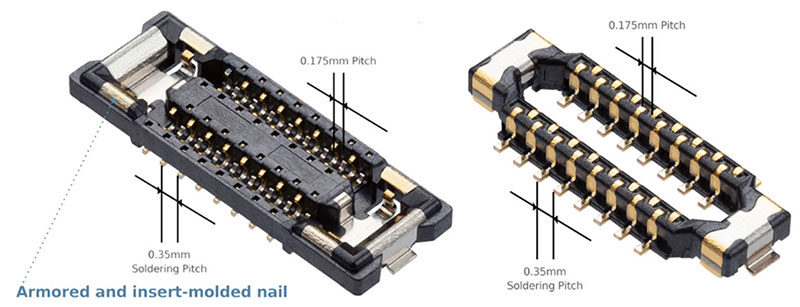

Figure 1 : The Molex Quad-Row board-to-board connectors use a staggered circuit layout that positions the contacts across four rows. The effect is that they maintain the desired 0.35 mm soldering pitch while providing a 0.175 mm contact pitch. (Image source: Molex)

Figure 1 : The Molex Quad-Row board-to-board connectors use a staggered circuit layout that positions the contacts across four rows. The effect is that they maintain the desired 0.35 mm soldering pitch while providing a 0.175 mm contact pitch. (Image source: Molex)

Here’s the trick: the connectors split the contacts on each side into physically staggered pairs, as is easily seen in the receptacle at the right in Figure 1. The outside contacts on each side are spaced at the standard soldering pitch of 0.35 mm. The contacts on the inside are offset by a contact pitch of 0.175 mm—but also have a 0.35 mm spacing. The result is that the contacts on each side of the connector achieve the closer 0.175 mm spacing but do not compromise the manufacturability of the product. Instead, they maintain the standard surface mount 0.35 mm soldering pitch.

Obviously, shrinking the connector could have compromised its strength and reliability. Molex ensures robustness thanks to interior armor and an insert-molded power nail—noted in the figure—to safeguard pins from damage during volume manufacturing and assembly. Molex also designed in a wide plug-to-receptacle mating alignment to facilitate proper positioning to ensure easy, secure mating and extremely low contact breakage rates.

The contacts contribute to reliable circuit operation. The signal contacts support currents to 0.3 amperes (A) as they have a 30 milliohm (mΩ) contact resistance. With a contact resistance of 20 mΩ, the power nail contact is rated to handle 3 A currents, meeting customer requirements for high power in a compact form factor.

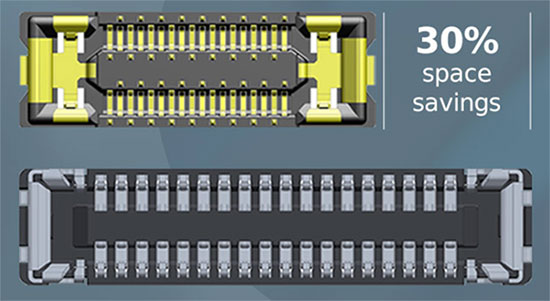

The overall effect of the staggered layout reduces the connector length by 30% compared to a standard connector (Figure 2).

Figure 2: The quad-row staggered design permits a contact spacing of one-half that of a standard connector and an overall reduction in length of 30%. (Image source: Molex)

Figure 2: The quad-row staggered design permits a contact spacing of one-half that of a standard connector and an overall reduction in length of 30%. (Image source: Molex)

Molex currently offers two configurations of the connector; 32 and 36 pins. The 32 pin version includes the Molex 2033890323 receptacle and the Molex 2033900323 plug. These are extremely small connectors as denoted by their dimensions. Both the receptacle and the plug are nominally 1.94 mm wide, 4.835 mm long, and 0.5 mm deep. The overall height when mated is 0.6 mm.

The 36 pin version includes the Molex 2033890363 receptacle and the Molex 2033900363 plug. The dimensions of the 36 contact connector parts are nominally 1.94 mm wide, 5.185 mm long, and 0.5 mm high. The overall height when mated is 0.6 mm.

Connector sets with higher contact counts are on the way.

The geometric efficiency of these connectors has released highly valuable printed circuit board (pc board) real estate for components and hardware needed to deliver added functionality for future designs.

Reading some background material, it turns out Molex has shipped more than 50 million quad-row connectors since 2020 in support of their original customer. This experience provides the reassurance of a proven, high-quality product and reliable delivery, critical elements for any project you may have.

Conclusion

We face shrinking form factors on a daily basis, so it’s reassuring to know that major board-to-board connector providers like Molex are working on viable solutions to make our job a little bit easier. The compact size and reliable performance of the Quad-Row board-to-board connectors make them ideally suited for a variety of applications requiring increasingly smaller pc boards and flex assemblies. Using these field-proven connectors creates nearly limitless opportunities for the miniaturization demands of devices like smartwatches, phones, wearables, and a widening array of IoT devices.

Have questions or comments? Continue the conversation on TechForum, DigiKey's online community and technical resource.

Visit TechForum