Enhance Safety and Boost Availability in Industry 4.0 Factories

When you’re designing Industry 4.0 production lines, safety is imperative. For example, subsystems like motors and drives are often required to meet International Electrotechnical Commission (IEC) 62061 Safety Integrity Level (SIL) 2 and International Standards Organization (ISO) 13849-1 performance level (PL) c. To meet these requirements, you can generally use contactors to safely connect and disconnect motors. For small motors rated under 55 kilowatts (kW), standard contactors can provide a simple and cost-effective approach.

As many of us have discovered, meeting IEC and ISO safety requirements for motors at higher power levels gets more complex and costly due to the need for coupling devices between the motor and standard contactors. The good news is that there are enhanced contactors available with a built-in failsafe that can be directly connected to motors rated from 55 to 250 kW, thereby reducing system cost and component count and enhancing reliability.

Let’s briefly review a simplified architecture using failsafe contactors for motors rated from 55 to 250 kW using innovative safety-rated contactors from Siemens as examples. We’ll close with a review of some of the challenges associated with using the Verband Deutscher Maschinen- und Anlagenbau (VDMA) and the Association of German Machine and Plant Construction standards for quantifying the performance of safety-rated contactors.

Simplification with safety-rated contactors

Contactors for power levels up to about 55 kW can be directly connected to the outputs of fail-safe controllers and safety relays to meet safety-rated application requirements. The outputs of these fail-safe controllers and safety relays are generally limited to 5 amperes (A) or less at 24 volts direct current (VDC). Since they don’t pack the punch needed to control high-power contactors, a coupling device is needed between the controller or safety relay and a standard contactor to boost the drive power. These coupling devices add cost, complexity, and space.

To address this, Siemens has developed an innovative approach that uses contactors with a fail-safe control input in addition to the standard drive coil. The fail-safe control input is designed to operate with an actuation current of about 5 milliamperes (mA) at 24 VDC, compared with the 5 A or more at 24 VDC needed for conventional contactors. This means you can drive the contactors directly from safety relays and fail-safe controllers.

Even though the fail-safe contactor is controlled by the fail-safe control input, the contactor coil is permanently connected to the supply voltage to ensure reliable operation (Figure 1).

Figure 1: Conventional contactors (left) require coupling devices (the two blue boxes in the upper right) that are not needed when using fail-safe contactors (right). (Image source: Siemens)

Figure 1: Conventional contactors (left) require coupling devices (the two blue boxes in the upper right) that are not needed when using fail-safe contactors (right). (Image source: Siemens)

Fail-safe operation

Siemens offers a range of innovative Sirius modular control options, including contactors with conventional AC/DC and integrated fail-safe control operation. The fail-safe operating mechanism can be optionally equipped with a remaining lifetime (RLT) signal that indicates the state of contact wear. This enables preventative maintenance, further improving system reliability and availability. The RLT circuit saves the contact wear information for each of the three main contacts. Contact wear is indicated with LEDs, and an additional relay output is generated when the RLT of the contact with the highest wear has dropped to 20%.

Since they can be connected to the output of a fail-safe controller, these contactors are referred to as F-PLC-IN contactors, and they can be physically identified by the yellow-marked terminal or coil cover of the fail-safe control input (Figure 2).

Figure 2: F-PLC-IN contactors like the 3RT2037-1SF30 (left) and the 3RT1056-6SF36 (right) can be visually identified by the yellow terminal or coil cover. (Image source: Siemens)

Figure 2: F-PLC-IN contactors like the 3RT2037-1SF30 (left) and the 3RT1056-6SF36 (right) can be visually identified by the yellow terminal or coil cover. (Image source: Siemens)

Safety by the numbers

The VDMA standard sheet 66413 recognizes four device types that you can use for safety evaluations:

- Type 1 devices are developed for use in safety functions like safety relays and fail-safe programmable logic controllers (PLCs) and meet specific SIL or PL requirements.

- Type 2 devices are not necessarily developed to meet specific safety requirements, and application data is needed to evaluate safe operation.

- Type 3 devices include wear-prone components like electromechanical contactors. They are not necessarily developed to meet specific safety requirements and can require extensive safety evaluation.

- Type 4 devices are developed for use in safety functions and don’t experience random failures.

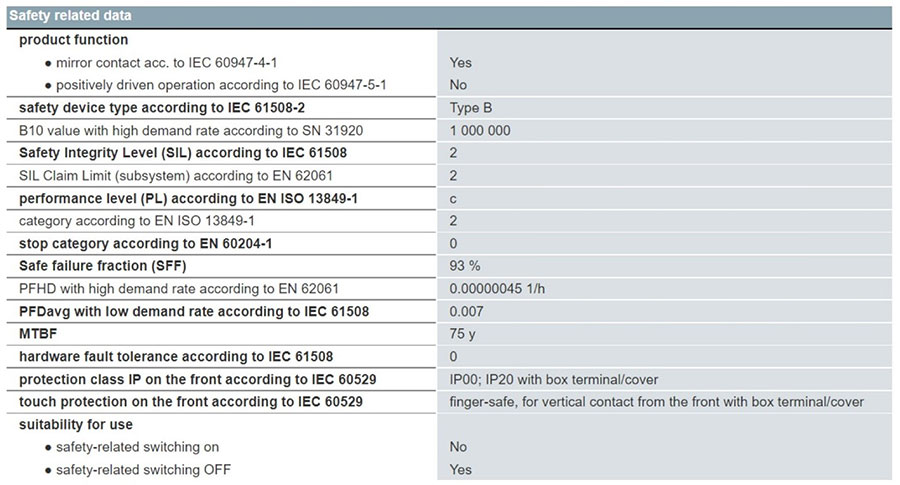

Sirius F-PLC-IN contactors have integrated electronics and are not purely electromechanical components, so they don’t qualify as Type 3 devices. They are instead Type 1 devices, meet specific SIL and PLC requirements, and come with comprehensive safety-related specifications. This simplifies the task of safety integrity calculation, compared with standard contactors (Table 1).

Table 1: Sirius F-PLC-IN contactors are VDMA Type 1 devices and are delivered with detailed safety-related data. (Image source: Siemens)

Table 1: Sirius F-PLC-IN contactors are VDMA Type 1 devices and are delivered with detailed safety-related data. (Image source: Siemens)

Conclusion

Contactors play an important role in Industry 4.0 automation systems where designers need to meet IEC 62021 SIL 2 and ISO 13849-1 PL c safety and reliability requirements while also working to reduce cost. As described, the innovative Sirius F-PLC-IN contactors from Siemens help you meet these requirements with fewer components and with reduced complexity.

Recommended Reading

How to Select and Apply Electromechanical Contactors for Heavy-Duty Three-Phase AC Motors

Have questions or comments? Continue the conversation on TechForum, DigiKey's online community and technical resource.

Visit TechForum