A Microswitch’s Clever Design Elegantly Balances Traditional Tradeoffs

At its core, engineering combines the art and skill of balancing tradeoffs among attributes such as size, weight, power, cost, performance, and manufacturability. Designers of both small components and large systems face this challenge. A close look at the redesign of a family of small switches to meet automotive requirements illustrates the innovation focus and the subtleties of design and manufacturing.

The automotive limit-switch dilemma

Momentary-contact and latching switches are basic, single-function devices that have existed seemingly forever and may appear straightforward to design and build. However, developing a switch that meets the many electrical and mechanical requirements, is reliable, and can be manufactured in high volume is surprisingly tricky. These switches must meet a list of demands regarding size, contact rating, activation force, actuation angle, and more.

Such were the challenges facing designers at Omron Corp. when it came to developing a small switch to indicate whether a car door was open or closed. The modern car door is thinner than ever and packed with many other functions, so a compact form factor was critical.

As a result, the pushbutton action is only a few millimeters, which ensures that the switch structure stops the actuator from contacting the pushbutton; otherwise, normal door slamming would damage the switch. Reliability issues and an IP67 rating for water and dust resistance in a harsh operating environment complicate matters further.

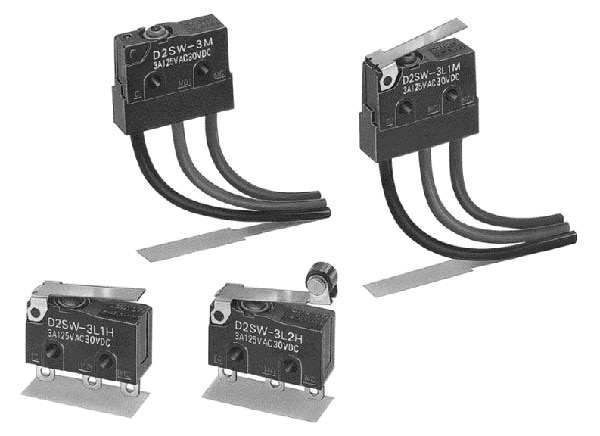

The type of switches required here are called snap-action limit switches. They have a restricted internal travel range, are sensitive, and are offered in many styles, including adjustable plunger or rod, toggle, arm lever, roller, cone, leaf, rotary actuator, spring, whisker, or cable. Today’s sealed ultra-subminiature switches, such as those in the Omron D2SW family (Figure 1), are descendants of the classic microswitch developed in the 1930s and still in widespread use. Their internal design and operation differ from the on/off switches used in a home appliance or a benchtop instrument.

Figure 1: The D2SW family exemplifies the classic snap-action limit switch that has served designers well for decades. (Image source: Omron Corp.)

Figure 1: The D2SW family exemplifies the classic snap-action limit switch that has served designers well for decades. (Image source: Omron Corp.)

The Omron team reviewed existing switch-activation arrangements such as horizontal action with a lever, without a lever, and with an angled cam. Each had benefits but also unacceptable tradeoffs related to angular offset when pushing the switch button, physical volume, long-term points of wear, and more.

New thinking points the way

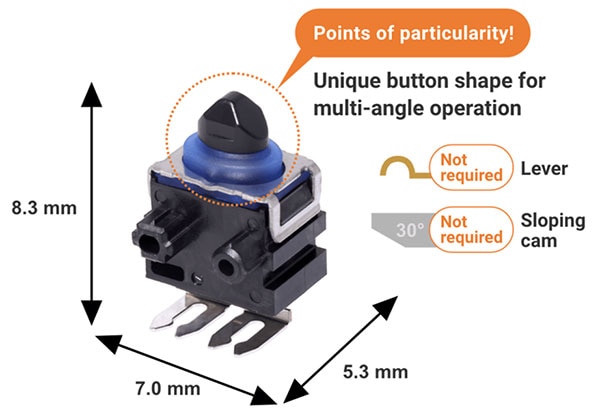

To overcome the challenges of designing a smaller, reliable limit switch that meets automobile door (and other) needs, the Omron designers took an innovative approach for their D2EW family of normally open (NO) and normally closed (NC) switches (Figure 2), such as the NO D2EW-B03H and the complementary NC D2EW-B02L. These compact, sealed switches can be operated in multiple directions and angles.

Figure 2: An innovative design allows the D2EW family of ultraminiature sealed switches to be operated from multiple actuation angles. (Image source: Omron Corp.)

Figure 2: An innovative design allows the D2EW family of ultraminiature sealed switches to be operated from multiple actuation angles. (Image source: Omron Corp.)

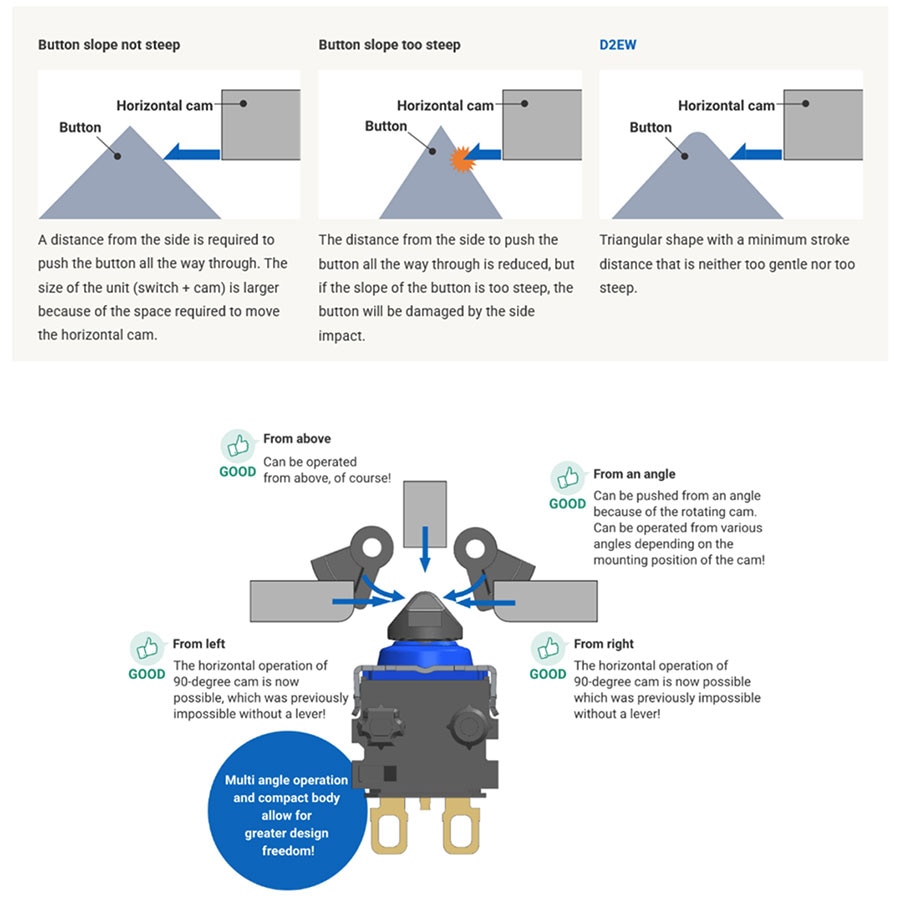

The Omron team realized a triangular button would enable horizontal operation without a space-consuming lever. They then determined the optimum angle of the slope of the button to implement a shape that can be securely pressed from above. This allows it to be opened and closed with minimum stroke movement and without needing a sloping horizontal cam and its associated space and complexity.

This button design allows the switch to be operated from multiple angles without a lever. It can open and close contacts horizontally with a stroke of only a few millimeters (Figure 3 (top)), and can also be operated when pressed from the vertical direction (Figure 3 (bottom)).

Figure 3 : The button of the D2EW switch is designed to minimize size and stroke distance (top) and can be actuated from above, at an angle, and from the left or right (bottom). (Image source: Omron Corp.)

Figure 3 : The button of the D2EW switch is designed to minimize size and stroke distance (top) and can be actuated from above, at an angle, and from the left or right (bottom). (Image source: Omron Corp.)

Meeting IP67 standards

Not surprisingly, this new button shape brought new problems. The unusual triangle-shaped pushbutton was extremely difficult to hermetically seal. Conventional circular pushbuttons use heat caulking, in which the resin rib is tipped toward the button and bites into the rubber cap to tighten it. However, the D2EW pushbutton is approximately four times the volume of the circular pushbutton, thereby increasing the size of the rubber cap, leaving no space for a resin wall.

The solution combined analysis with trial and error. The designers opted to seal the case and rubber cap by snap fit, where the rubber cap is sandwiched between the case and cover with sufficient pressure to satisfy IP67 requirements. However, unlike a circular cap, where pressure can be applied evenly in all directions, this cap's oval base led to tightness variations. To overcome this, the team devised a shape that makes the button shaft as close to a circle as possible. They also adjusted the rubber cap's shape and the rubber's thickness to compensate for load variations. Over several months of trial and error, they arrived at the optimal shape.

There are also internal changes. The D2EW devices have a pushbutton with a slider at the bottom, which slides sideways when the button is pressed. This is unlike a conventional pushbutton and slider, which move in unison. Integrating the contact surfaces into a single surface resulted in an easily assembled structure that can open and close the contact points with the fewest possible component elements.

Conclusion

The D2EW family’s unique and innovative button cap and internal design allow it to be activated using straight-on pushes, as well as from any angle despite only a few millimeters of actuator travel. The design makes it an excellent fit for today’s thinner and more crowded automobile doors while also allowing it to endure door slamming and harsh conditions.

Have questions or comments? Continue the conversation on TechForum, DigiKey's online community and technical resource.

Visit TechForum