Simplifying the Sourcing of Fiber-Optic Cables

2024-02-22

Machine builders continue to adopt fiber-optic cables in lieu of traditional copper-conductor cabling. Driving this trend is the way fiber-optic cables offer superior bandwidth, reduced electromagnetic interference, and enhanced data security for industrial applications that rely on high-speed large-scale data transfers.

Challenges of traditional cable sourcing

Despite the extra waste and cost involved, machine builders traditionally source cables in bulk on large reels or spools holding hundreds to thousands of feet of cable (Figure 1). With this approach, they also assume the time-consuming tasks of measuring, cutting, and connectorizing the cables for installation.

Figure 1: Fiber-optic cable is often bought in bulk. (Image source: Dreamstime)

Figure 1: Fiber-optic cable is often bought in bulk. (Image source: Dreamstime)

Fiber-optic cable is also sold in standard pre-cut lengths. These lengths offer convenience, though they are rarely the perfect fit for the application and cable layout at hand. In contrast, purchasing from specialized vendors who provide cutting services allows customization, although some programs’ long lead times and minimum order quantities can be challenging for builders working on small or custom projects.

Figure 2: Panduit Opti-Core indoor-outdoor all-dielectric cable supports various data and network requirements. The fiber-optic cable features water-blocking technology, high density, 900-μm tight-buffered fibers, and easy connectorization. Aramid yarn members impart strength. (Image source: Panduit)

Figure 2: Panduit Opti-Core indoor-outdoor all-dielectric cable supports various data and network requirements. The fiber-optic cable features water-blocking technology, high density, 900-μm tight-buffered fibers, and easy connectorization. Aramid yarn members impart strength. (Image source: Panduit)

In some cases, large OEMs can also purchase cable directly from manufacturers. Custom construction and lengths are possible, though quantities often need to be high enough to justify such purchasing arrangements, and orders may need to be harmonized with manufacturing schedules.

In contrast, purchasing from online electronic-component distributors can avoid availability issues as well as minimum-order requirements. Now it’s even possible to order cut-to-length fiber-optic cables this way.

Challenges of cutting fiber-optic cable

Fiber-optic cables require precise cutting and connectorizing (Figure 3). Each fiber must be cleanly bisected with specialized cleavers to yield a smooth end face that’s perpendicular to the fiber length. Cutting must also be executed in a clean environment free of contaminants. Otherwise, the fibers will prove more difficult to properly connectorize and will exhibit light scattering as well as other issues that degrade transmission quality and efficiency. Because optical strands are more delicate than the copper strands of traditional cable options, the former must not be excessively bent, twisted, or crushed during cutting.

Figure 3: High-precision cleavers can be expensive. (Image source: Dreamstime)

Figure 3: High-precision cleavers can be expensive. (Image source: Dreamstime)

Improper cutting of fiber-optic cables is more likely in the field than in a controlled manufacturing setting, especially if undertrained personnel are tasked with the job. What’s more, identifying and correcting any issues caused by compromised cables can be time consuming at best and impossible at worst. That’s especially true where an especially suboptimal cut leaves connectors sensitive to intermittent issues that fluctuate with environmental factors that vary with temperature and humidity.

Figure 4: Precisely cut fiber ends are needed for all types of connectorizing and splicing. Shown here is a Panduit fiber-termination enclosure that allows splicing of up to 360 fibers while protecting cables, terminations, and splice trays from damage. (Image source: Panduit)

Figure 4: Precisely cut fiber ends are needed for all types of connectorizing and splicing. Shown here is a Panduit fiber-termination enclosure that allows splicing of up to 360 fibers while protecting cables, terminations, and splice trays from damage. (Image source: Panduit)

Another challenge of cutting fiber-optic cable is that any glass fragments generated can in fact be dangerous. So, personnel tasked with cutting such cable should wear protective eyewear and clothing. In addition, personnel tasked with cutting such cable should use the cleaver equipment and technique appropriate for the single or multi-mode fiber type at hand.

Digi-Spool logistical benefits

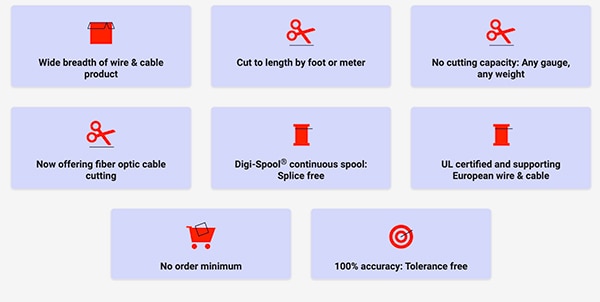

DigiKey’s Digi-Spool program addresses cable-sourcing issues by letting machine builders specify and purchase copper-strand cable as well as fiber-optic cable in one-foot increments — even many thousands of unspliced feet. Using the appropriate equipment and technique, DigiKey professionals cut the product to within a +3% tolerance (and never shorter), load it onto a spool, and ship it.

Related: Have you heard of DigiKey Digi-Spools?

99% of all cable purchased through the Digi-Spool program for a North American destination is cut and shipped the same day. In Europe, the Middle East, and Africa (EMEA), cable ordered through the Digi-Spool program can be delivered anywhere in as little as 48 hours … and in the Asia-Pacific (APAC) region in a little as 72 hours.

Figure 5: DigiKey has partnered with fiber-optic cable manufacturer Panduit to provide high-quality cables that are professionally cut to order. This service ensures machine builders get industry-standard cables tailored to specific requirements without the waste that can be associated with other sourcing approaches. (Image source: DigiKey)

Figure 5: DigiKey has partnered with fiber-optic cable manufacturer Panduit to provide high-quality cables that are professionally cut to order. This service ensures machine builders get industry-standard cables tailored to specific requirements without the waste that can be associated with other sourcing approaches. (Image source: DigiKey)

Now, DigiKey Digi-Spool wire and cable cutting services also help machine builders leverage the unrivaled benefits of fiber-optic connectivity sans the challenges of processing it for installation. UL certification from the manufacturer is maintained. The customization service reduces waste and optimizes inventory for more sustainable and cost-effective production processes.

Related: Digi-Spool Wire & Cable Cutting Service | DigiKey

Impact on Design and Production for Machine Builders

As demand for intelligent and connected machinery grows, services such as the Digi-Spool program are expected to become increasingly integral to the automation industry.

The Digi-Spool service lets machine builders quickly source fiber optic cables for prototypes, one-off machine builds, and stock designs for automation. For rapid prototyping and iterative design, the fast-ship aspect of the Digi-Spool service lets machine builders procure small quantities of fiber optic cables for testing and design validation. That in turn streamlines the design-to-production cycle. For machine building in competitive markets, the turnkey of the Digi-Spool service lets OEMs trim cost and time to market by eliminating stock-room management and assembly tasks.

Conclusion

DigiKey’s Digi-Spool cut-to-length wire and cable service is supporting the adoption of fiber-optic connectivity in industrial applications. Panduit fiber-optic cable is available through the program so machine builders have the option to specify a widely accepted brand from a distributor that is certified to maintain UL labeling on custom cuts. The cut-to-order service is poised to grow with increasing adoption of fiber optics in industrial automation.

Disclaimer: The opinions, beliefs, and viewpoints expressed by the various authors and/or forum participants on this website do not necessarily reflect the opinions, beliefs, and viewpoints of DigiKey or official policies of DigiKey.