Selecting Space-Grade Connectors for LEO Satellite Applications

Contributed By DigiKey's North American Editors

2024-12-10

The satellite industry is experiencing rapid growth, particularly in the area of low earth orbit (LEO) satellites. However, the harsh LEO environment presents significant challenges for designers. Exposure to a vacuum, atomic oxygen, intense ultraviolet (UV) radiation, and extreme temperature fluctuations can lead to outgassing, material degradation, and connector failure, potentially compromising mission-critical systems.

To ensure mission success, designers must understand the challenges of operating in space and select connectors from reliable sources that incorporate the advanced materials and technologies necessary to meet the demands of LEO conditions.

This article briefly reviews the challenges of designing for LEO applications and discusses strategies for mitigating the environmental effects. It then introduces appropriate connectors from Cinch Connectivity Solutions that can help meet these challenges.

Environmental challenges in LEO and their impacts on connectors

Designers of LEO satellites face unique environmental challenges. While the environment is not as harsh as deep space, LEO satellite connectors and other components must withstand outgassing, radiation and corrosion, temperature extremes, and vibration and shock.

1. Outgassing

Outgassing describes the release of gases from non-metallic materials when they are subjected to heat or a vacuum. It is a significant concern in LEO environments. Plastics are widely used in connectors for their excellent insulating properties, and some metals used in connectors may contain microscopic gas bubbles trapped during manufacturing. When connectors are manufactured at sea level, these gas bubbles are not subject to the forces applied by differences in pressure inside and outside the material.

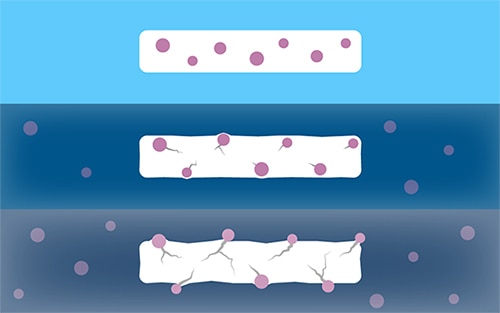

However, in the vacuum of space, the pressure differentials significantly increase, releasing these trapped gases. This outgassing can lead to small cracks and fissures that affect the mechanical strength of the connector (Figure 1).

Figure 1: Outgassing leads to small cracks and fissures that affect a connector’s mechanical strength. (Image source: Cinch Connectivity Solutions)

Figure 1: Outgassing leads to small cracks and fissures that affect a connector’s mechanical strength. (Image source: Cinch Connectivity Solutions)

Outgassing can also damage sensors such as cameras by forming a coating layer. It may even lead to short circuits between connectors and components, jeopardizing a mission.

While the vacuum of space primarily drives outgassing, other environmental factors can increase its likelihood. For example, the weakening of polymers caused by UV radiation and exposure to atomic oxygen make it easier for trapped gases to escape.

2. Radiation and atomic oxygen exposure

Constant exposure to the sun’s UV radiation can damage plastics used in connectors. Ionizing radiation can lead to charge accumulation on connectors, potentially causing electrostatic discharge events. Atomic oxygen, abundant in the LEO environment and formed when UV radiation reacts with oxygen, is highly reactive and can erode connector materials, especially polymers and some metals. For example, polytetrafluoroethylene (PTFE), a common plastic insulation material in connectors, reacts when exposed to atomic oxygen and UV radiation, leading to wear. Atomic oxygen is particularly reactive with silver, causing oxidation and impacting electrical conductivity and contact resistance.

3. Extreme temperature fluctuations

LEO satellites experience temperature swings from +125°C in sunlight to -65°C in the Earth’s shadow, with some external components potentially facing temperatures from -270°C to +200°C. This leads to thermal cycling, which stresses and can exacerbate minor imperfections in connectors. The differences in the coefficient of thermal expansion (CTE) between connector materials and associated components can result in uneven thermal cycling, leading to incompatible combinations and potential failure.

4. Vibration and shock

Intense vibration during launch can compromise connector integrity. Side-to-side (lateral axis) and forward-to-backward (thrust axis) motions can lead to misalignment or breakage in connector contact areas. Shocks generated at launch when the payload separates from the launch vehicle can loosen connectors and create fatigue points.

Strategies for mitigating LEO environmental effects

Hermetic sealing is recommended to mitigate many of these risks. Hermetic sealing protects internal components from the vacuum of space and prevents internal gases from escaping. It also prevents air, gas, and moisture from penetrating the assembly.

To help ensure design success, there are several standards relevant to space applications:

- ASTM E595 outgassing test method for materials in vacuum environments measures total mass loss (TML) and collected volatile condensable materials (CVCM) at +125°C and +25°C, respectively. Typical acceptance criteria are: TML ≤ 1.00%, CVCM ≤ 0.10%.

- NASA EEE-INST-002 instructions for electrical, electronic, and electromechanical (EEE) parts selection, screening, qualification, and derating establishes reliability levels for EEE parts based on mission needs.

- NASA SSP 30426 establishes International Space Station (ISS) external contamination control requirements.

- NASA SP-R-0022A defines vacuum stability requirements for polymeric materials.

Connectors should be selected per these standards to ensure they meet the rigorous requirements of space missions.

Technology Readiness Levels (TRL), developed by NASA in the 1970s, provide a standardized method for estimating the maturity of technologies on a scale from 1 (basic principles observed and reported) to 9 (flight proven). TRLs play a crucial role in space component selection for several reasons:

- Risk reduction: Higher-TRL components have been proven in relevant environments or actual space missions.

- Cost management: Using higher-TRL components can reduce development and testing requirements.

- Progress tracking: TRL allows monitoring of technology development from concept to flight-ready status, aiding in planning and decision-making during spacecraft development.

- Common language: TRLs facilitate discussion of maturity across different space technologies.

- Integration ease: Higher-TRL components are generally easier to integrate into existing systems, influencing selection decisions.

Connector solutions for LEO

To address the design requirements of LEO applications, Cinch Connectivity Solutions offers its Cinch Space Mission Solutions portfolio of connectors. These are designed to meet the challenges related to LEO satellites such as CubeSats and NanoSats, which are tightly constrained in size and weight.

Stacking connector jumpers

Cinch’s CIN::APSE stacking connector jumpers provide solderless, high-density custom interconnects for applications such as board-to-board, flex-to-board, and component-to-board connections in LEO satellites. Key features include:

- coplanar and right-angle board-to-board connections for flexibility in satellite design and layout;

- combination of RF, power, signal, and high-speed data in a 1 millimeter (mm) package;

- NASA approval at TRL 9, indicating flight-proven reliability;

- and proven performance under extreme mechanical shock, vibrations, and thermal conditions.

A typical example is the 4631533093 (Figure 2). This flexible printed circuit board (pc board) compresses to join a stacking connector mounted on a rigid pc board.

Figure 2: Shown is the 4631533093 flexible stacking connector jumper that connects rigid pc boards. (Image source: Cinch Connectivity Solutions)

Figure 2: Shown is the 4631533093 flexible stacking connector jumper that connects rigid pc boards. (Image source: Cinch Connectivity Solutions)

The 4631533093 has 25 conductors, is 3 inches (in.) long, has a pitch of 0.025 in., and has exposed ends measuring 0.131 in.

Space-screened micro-D connectors

For miniaturized airborne electronics and data processing equipment, and where shorter signal paths are needed in compact satellite designs, Cinch provides the space-screened Dura-Con micro-D connectors. Notable features include twist pin contacts and machined sockets for durable seven points of contact, MIL-DTL-M83513 compliance (specific to micro-D connectors), nickel plating, and ethylene tetrafluoroethylene (ETFE) insulated wires. The DCCM25SCBRPN-X2S 25-pin micro-D receptacle is a good example (Figure 3).

Figure 3: The DCCM25SCBRPN-X2S is a 25-pin, space-screened micro-D receptacle. (Image source: Cinch Connectivity Solutions)

Figure 3: The DCCM25SCBRPN-X2S is a 25-pin, space-screened micro-D receptacle. (Image source: Cinch Connectivity Solutions)

This receptacle has two rows with a pitch of 0.050 in. and row-to-row spacing of 0.043 in. It has a gold contact finish, can handle up to 3 amperes (A), and exceeds the LEO outgassing requirements of ≤ 1.0% TML and ≤ 0.1% CVCM.

Attenuators

Cinch’s Qualified Part for Space (QPS) attenuators are specifically designed for space applications. They meet ASTM E595 and MIL-DTL-3993 outgassing standards and come with standard values of 1, 2, 3, 6, 10, and 20 decibels (dB). Custom values from 0 to 20 dB are available. A typical example is the SQA-0182-01-SMA-02 (Figure 4). This 1 dB attenuator features DC to 18 gigahertz (GHz) performance, 2 W average power handling capability (500 W, peak), and an operating temperature range of -55°C to +125°C.

Figure 4: The SQA-0182-01-SMA-02 is a 1 dB attenuator specifically designed for space missions. (Image source: Cinch Connectivity Solutions)

Figure 4: The SQA-0182-01-SMA-02 is a 1 dB attenuator specifically designed for space missions. (Image source: Cinch Connectivity Solutions)

Conclusion

Designers of LEO space missions need connectors that perform reliably in the face of challenges such as outgassing, temperature, UV and ionizing radiation, and vibration and shock. By relying upon proven suppliers such as Cinch Connectivity Solutions, they can benefit from a range of solutions designed to the highest standards for space missions to ensure design success.

Disclaimer: The opinions, beliefs, and viewpoints expressed by the various authors and/or forum participants on this website do not necessarily reflect the opinions, beliefs, and viewpoints of DigiKey or official policies of DigiKey.