Why Polyurethane Foam is so Good for Gasketing, Vibration Management, and Energy Control

Noise, vibration, and shock represent unwanted energy transfers that are problematic in modern electronic design. Their effects can vary from annoying to catastrophic. Most of the solutions involve energy-absorbing foam of various shapes, densities, and thicknesses, used as gaskets, bumpers, and damping panels. These energy-absorbing foams are available from companies such as Aearo Technologies, a subsidiary of 3M, marketed under the E-A-R (energy absorbing resins) brand.

I saw a great example of this company’s energy-absorbing products. In a previous life, I worked for a company that designed and manufactured low-frequency spectrum analyzers. One of the main applications was shock and vibration measurements. It was in that life that I came to know the E-A-R brand: it produced energy-absorbing products that converted mechanical energy in the form of shock and vibration into heat.

One of the shows I attended was held at a country club. E-A-R showcased their energy-absorbing products by offering golf balls made from their technology. If one of those golf balls was dropped on the floor, it just came to rest; zero bounce. If you hit it with a club, it would go as far as the club carried it and drop dead: it was quite amazing to see. Luckily, they were painted E-A-R blue so they couldn’t be substituted for a normal golf ball. They were beautiful examples of what E-A-R energy-absorbing products could do.

Energy absorption with consistent shape and temperature tolerance

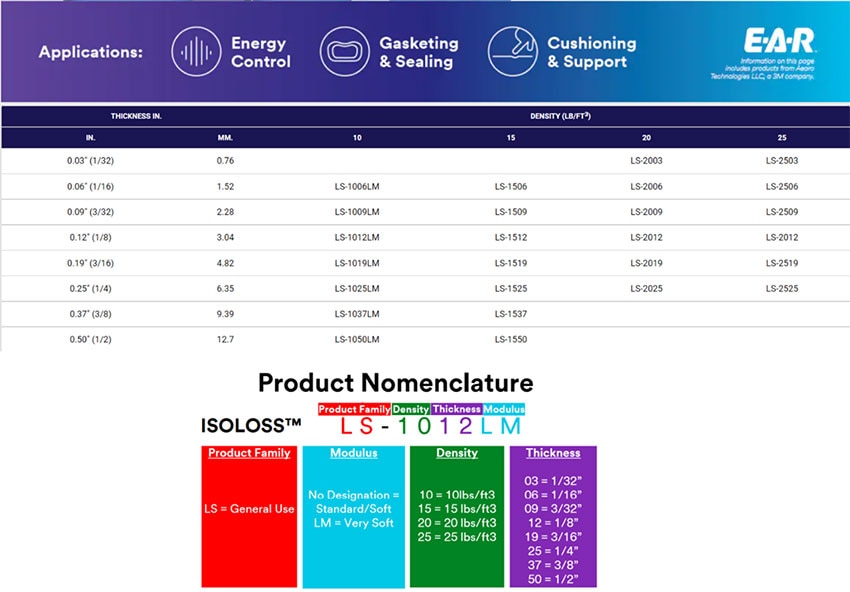

Today, 3M’s ISOLOSS LS is an open-cell microcellular polyurethane foam. It is a durable, energy-absorbing material with a low compression set and consistent force deflection, useable over a broad temperature range.

The technology is available in multiple densities and thicknesses (Figure 1). Gaskets can isolate mechanical vibration from a cooling fan, foam tapes can close gaps in access panels, sheets can dampen vibration in enclosure walls and doors, and bumpers can cushion shocks.

Figure 1: ISOLOSS LS foam products are available in a range of densities and thicknesses, providing design flexibility. (Image source: 3M)

Figure 1: ISOLOSS LS foam products are available in a range of densities and thicknesses, providing design flexibility. (Image source: 3M)

Polyurethane foam is used in three different classes of applications: gasketing, cushioning and support, and energy control. Gasketing requires the ability to seal gaps, absorb mechanical shock and vibration, and provide a seal between mating surfaces. The gasket on an air conditioner filter rack uses polyurethane foam to seal the filter housing and hold the filter in place. Cushioning and support involve isolating objects from each other such as a bumper on a door that closes a switch to monitor the door closure. The bumper cushions the switch, reducing the shock of the door closure. Energy control applications reduce vibration and shock by dissipating mechanical energy as low-level heat, such as a vibration damping pad on a large metal panel.

The two key characteristics of polyurethane foam are compression set and compression force deflection. These characteristics describe the ability of the foam to retain its shape and to provide a force against an object that is compressing it.

Compression set is a measure of the permanent deformation of the foam after sustained compression. A low value of compression set indicates that the foam will return to its original thickness after recurring or continuous compression. This is important for applications like gasketing, where the foam must return to its uncompressed state in order to maintain a good seal when returned to its compressed state. ISOLOSS LS foams experience less than 1% compression set at room temperature.

Compression force deflection (CFD) represents the firmness of the foam at various degrees of compression. Plots of CFD as a function of compression provide some insights into designing with these foams. For more on CFD, see “How to Protect Sensitive Electronic Equipment from Shock, Vibration, and Temperature”.

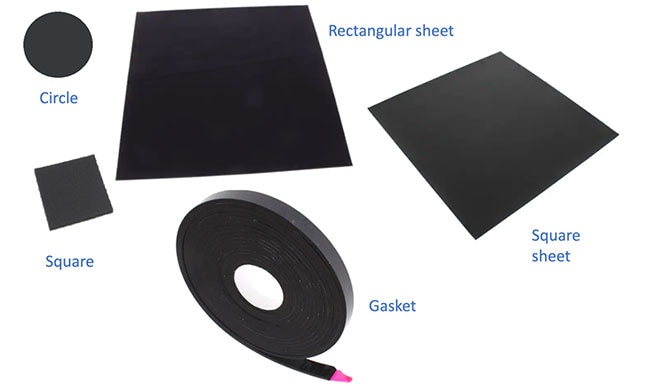

3M ISOLOSS LS foam is available in a variety of forms, including gasket strips, circular and square spots, and square and rectangular sheets (Figure 2).

Figure 2: ISOLOSS LS polyurethane foam is available in a variety of useful shapes that can be easily adapted to a full range of applications. (Image source: 3M)

Figure 2: ISOLOSS LS polyurethane foam is available in a variety of useful shapes that can be easily adapted to a full range of applications. (Image source: 3M)

The smaller circular and square pads like the LS-2506-PSA-1-CIRCLE-50PK and the LS-2006-PSA-2-X2-50PK are commonly used as bumpers. Strips like the LS-1025LM/PSA 0.75"X180"-1RL, a 0.75 in. wide, 0.25 in. thick strip with a 10 lb/ft3 density are useful for gasketing.

The larger sheet forms, like the LS-1506/PSA-5"X7"-10PK and the LS-1006LM-PSA-12-X12-6PK, are useful in acoustic and vibration damping applications. They are applied to panels and doors to change their vibration modes. Vibration damping works by dissipating energy as the damping foam undergoes extension and compression due to the flexural stress of the base layer (Figure 3).

Figure 3: The ISOLOSS LM foam which is adhesively bonded to the base layer dissipates energy as it is flexed. (Image source: 3M)

Figure 3: The ISOLOSS LM foam which is adhesively bonded to the base layer dissipates energy as it is flexed. (Image source: 3M)

Damping increases with the increased thickness of the damping foam layer. Changing the foam density also impacts the damping. It is not necessary to cover the entire panel; covering as little as 25% of the panel area will noticeably reduce the vibration level.

Conclusion

It’s interesting to see technologies that we sometimes take for granted shown in a completely new application, especially when it’s for fun. The golf ball demonstration truly showed the potential of energy-absorbing foam. 3M’s ISOLOSS LS products continue to solve vibration, shock, and sealing problems while retaining their shape and sealing ability throughout their lifetimes. In the process of doing so, they tolerate extreme environments and are flame and chemically resistant.

Have questions or comments? Continue the conversation on TechForum, DigiKey's online community and technical resource.

Visit TechForum