Use Electromechanical Relays to Solve Modern Interface Problems

One of the challenges in integrating systems is interfacing an existing subsystem with a new or different one. Sometimes, when both sides' input/output characteristics are standard and known, a level-shifter/translator IC, such as the Texas Instruments SN74AUP1T57DCKR, can accommodate different digital signal levels on its inputs and outputs and easily solve the problem (Figure 1).

Figure 1 : When two interfaces are standard and well-defined, an off-the-shelf IC, such as the SN74AUP1T57DCKR, can quickly and easily solve the problem. (Image source: Texas Instruments)

Figure 1 : When two interfaces are standard and well-defined, an off-the-shelf IC, such as the SN74AUP1T57DCKR, can quickly and easily solve the problem. (Image source: Texas Instruments)

The challenge is that there are many scenarios where the interconnection between the older and newer systems is not easily implemented. Often, the characteristics of one or both sides of the interface are not known or are poorly defined, so using a standard component is not feasible.

This was the problem I faced in two separate situations. I could easily and neatly solve the problem in each case using a modern version of the nearly 200-year-old electromechanical relay (EMR). Invented around 1835, the EMR is usually credited to American scientist Joseph Henry.

While relays may seem archaic compared to using an optocoupler or a solid state relay (SSR), there are many cases when their “old-time” virtues are very beneficial. Hundreds of millions of such relays are sold yearly; while many are for replacement, a substantial fraction go into new designs.

Relay types fall into three general groups: small-signal devices for contact currents under 2 amperes (A), power relays for higher currents, and radio frequency (RF) relays. RF relays usually handle small signals in the megahertz and gigahertz ranges. In addition, there are other family siblings, such as audio relays and reed relays for automatic test equipment (ATE). Further, relays have many contact configurations, starting with the basic single-pole/single-throw (SPST) version and going up to units with multiple contacts.

I’ll be honest: I really like EMRs for many reasons:

- They are rugged and reliable.

- They provide near-perfect galvanic (ohmic) isolation.

- The input and output current/voltage ratings are largely independent.

- They come in a wide range of ratings for the coil and contacts.

- They usually have a compatible socket-pinout version, which simplifies wiring and debugging.

- They often come with multiple normally open (NO)/normally closed (NC) contacts, which prove useful.

- They provide a visual indication via armature position, showing if they are energized.

- They have a very satisfying audible “click” when they open or close.

In short, they are no-hassle, flexible, and elegant problem solvers. As for reliability, a quality relay used within its specifications will last for millions of cycles and tens of years.

My situation was relatively simple since the “signals” I was dealing with were contact closures, sometimes called “dry contacts,” in which the driven system wants to see a basic continuity connection between its two wires. Let’s look at my problems and how a simple relay solved each one.

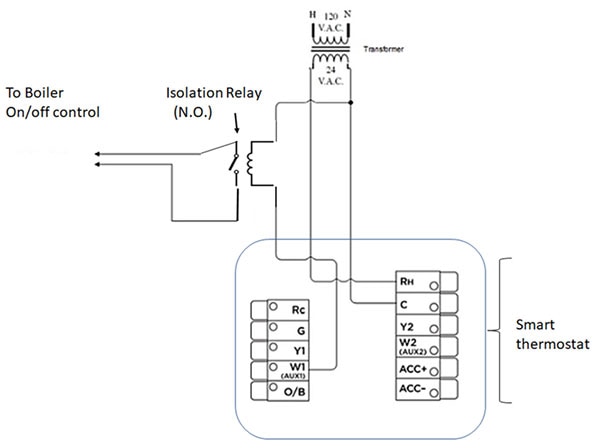

Challenge #1: Upgrading a heating control system

I “volunteered” to help a friend upgrade a heating-only system control from a basic, functioning, old-fashioned thermostat with a simple temperature-driven on/off function to a more sophisticated, smart, Wi-Fi-enabled unit. The old thermostat control was similar to the classic T87F from Honeywell (Figure 2). The T87F was introduced in the early 1960s, and though it is no longer offered for sale, millions were installed, and many are still in use due to its extremely reliable bimetallic thermal strip and hermetically sealed mercury switch.

Figure 2: Introduced in the 1960s, many of the millions of installed T87F Honeywell thermostats are still in use due to their extremely reliable bimetallic thermal strip and hermetically sealed mercury switch. (Image source: New York Historical Society)

Figure 2: Introduced in the 1960s, many of the millions of installed T87F Honeywell thermostats are still in use due to their extremely reliable bimetallic thermal strip and hermetically sealed mercury switch. (Image source: New York Historical Society)

I took a quick look at the existing thermostat and saw it had just two wires, so I thought, “How hard could this be?” Especially as its output action was a simple contact closure. That proved not to be the situation at all. The smart thermostat documentation showed many possible configurations and options for wiring when going from a two-wire unit to a new, much smarter, three-wire unit.

First, the new thermostat needed to be powered via a 24 volt AC (VAC) transformer, so an extra lead was required between the heating, ventilation, and air conditioning (HVAC) controller and the thermostat. Fortunately, a third unused lead was already in place (thank you, whoever did that!) So, that part of the problem was a non-issue.

There were many ways shown to connect the new, three-wire system to the existing two-wire contact closure depending on the vendor of the system controller (which in this case was pretty new), whether it was heat only versus heat plus AC, and how you wanted to deal with galvanically isolating the new thermostat from the existing controller.

One option was an optoisolator or SSR, but I wasn’t sure about voltage and current levels or if an SSR output that is “on” looks enough like a true contact closure, as there is a small voltage drop at the SSR output. The easier and less worrisome option was to use a relay for isolation similar to the IDEC RY2S-UAC24V. This general-purpose double pole, double throw (DPDT) relay has a 24 VAC coil and 3 A contacts in a basic translation/isolation circuit (Figure 3). Obviously, switching speed was not a concern in this situation.

Figure 3 : My problem of interfacing a modern smart thermostat to a new, simple two-wire heating-system controller was solved with a relay having a 24 VAC coil. (Image source: Bill Schweber)

Figure 3 : My problem of interfacing a modern smart thermostat to a new, simple two-wire heating-system controller was solved with a relay having a 24 VAC coil. (Image source: Bill Schweber)

The good news is that it all worked fine the first time! You can’t beat that.

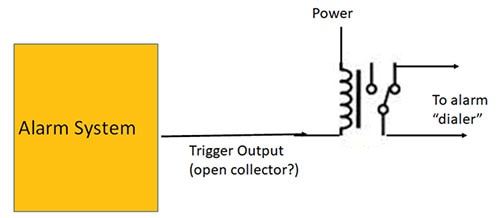

Challenge #2: Updating a security system dialer from landline to cellular

I was asked by another friend to help replace the now-obsolete landline telephone dialer on a home security system with a modern wireless cellular unit. As a simple two-wire closure triggered the old and new units, I hoped this would be a drop-in replacement; it was not.

The previous dialer required a transition from an “open” to a “closed” contact pair to trigger it, while the manual of the new one said it needed a transition from ground to “open circuit” as its trigger. Unfortunately, “open circuit” is one of those sometimes-ambiguous terms: did that mean “floating” (truly open), or would disconnecting the line via an open-collector output be sufficient?

Adding to the challenge, the documentation regarding the output pin of the alarm-control unit driving the dialer was unclear as to its electrical nature: it might have been an open-collector structure, or it might not. Thus, I could not say for sure if the control unit's output was at least potentially electrically compatible with the dialer's input needs.

I thought about it for a while and distilled the issue down to this: what I had was an output that went from high to low with an unclear structure, and what I wanted was for it to look like a DC signal going from ground to open.

Again, an EMR to the rescue. In this case, one similar to the KEMET UA2-5NU general-purpose DPDT relay with a 5 volt DC (VDC) coil and 1 A contacts seemed like a flexible, risk-free way to address these issues. I connected the coil between the supply rail and the active output of the control unit, then used the unenergized relay contacts in NC mode to connect the input of the dialer to true ground (Figure 4). When the control unit's output went low (pulled down), it energized the coil, which opened the NC relay contacts and provided a true open circuit to the dialer input.

Figure 4: A low-voltage DC relay accomplished the translation and signal inversion between the poorly defined output of the alarm-system trigger and the new wireless dialer. (Image source: Bill Schweber)

Figure 4: A low-voltage DC relay accomplished the translation and signal inversion between the poorly defined output of the alarm-system trigger and the new wireless dialer. (Image source: Bill Schweber)

Problem solved! The relay functioned as both a level shifter and signal inverter and gave me galvanic isolation as a bonus.

Conclusion

These two EMR solutions are simple yet elegant and effective problem solvers. What’s not to like? The lesson is not hesitating to consider tried-and-true components as they can offer simplicity, functionality, and flexibility. As for me, I’ll keep volunteering to help; it’s unpredictable and sometimes frustrating, but ultimately rewarding.

Have questions or comments? Continue the conversation on TechForum, DigiKey's online community and technical resource.

Visit TechForum