Know the Differences Between Compatible and “Compatible” Coaxial Connectors to Avoid Costly Mistakes

A measuring instrument uses a 3.5 millimeter (mm) connector, while your coaxial cables use 2.92 mm connectors: they look compatible. What effect will it have on your measurement? Can you connect to the instrument with SMA connectors, or will it damage the input connectors? Welcome to the strange world of connector mating, where making a mistake can destroy an input connector on an expensive instrument necessitating costly repair. How do you avoid making such a mistake?

Connector compatibility is usually the result of forethought in the design of a connector family. This is often an incestuous process where a new connector is designed based on an older and successful existing design with the intention of increasing the connector bandwidth and electrical performance. Even if compatibility is intended, care is required to prevent needless damage. Attention to some simple procedures may save you from expensive repairs.

Connector quality grades

Coaxial connectors are generally designed and manufactured to operate within specific quality grades or classes. There are three grades of connectors; metrology, instrument, and production.

Metrology-grade connectors are manufactured to the highest precision and quality standards. This grade of connector is intended for use in measurement calibration standards, which require the highest accuracy and precision and allow traceability to national standards. In this connector grade, the mating interface is tightly controlled, and clearance, flatness, and pin depth are held to the highest tolerances. This class of connectors has the highest cost.

The mid-range connector quality level is the instrument grade connector. This grade connector is intended for use in instruments and is characterized by good, repeatable performance and the ability to make accurate measurements with good signal integrity. They are commonly found in test and measurement equipment intended for laboratory use. Instrument grade connectors generally offer the longest life with the greatest specified number of mating operations.

The lowest-quality level connectors are the production or commercial-grade connectors. Connectors in this class are commonly used in production and manufacturing. They are intended for general-purpose field applications where assembly simplicity and low cost are the driving concerns. Mechanical tolerances are much looser than in the other quality grades. The number of mating operations for these connectors is commonly more limited, and they generally have the lowest cost.

Interchangeable connector types

The common 50 Ω coaxial connectors found in instruments are listed in Table 1. The notes column lists their compatibility.

Table 1: Characteristics and compatibility of coaxial connectors commonly used in instruments. (Table source: Art Pini)

Table 1: Characteristics and compatibility of coaxial connectors commonly used in instruments. (Table source: Art Pini)

There are two broad areas of compatibility. The first is mechanical: do the connectors fit together? The second is electrical: do the connectors have the bandwidth and impedance match to guarantee signal integrity?

The connectors specified by IEEE Std 287 are metrology or instrument-grade connectors. The SMA connectors specified by MlL-STD-348 are production-grade connectors, although some manufacturers supply “precision” versions of the connectors with tighter mechanical tolerances and extended bandwidth.

The table stresses that mating connectors from different quality classes must be done with care.

The 2.4 mm and 1.85 mm connectors are both instrument grade and so can be mated. Note that the bandwidth of this mating drops to that of the lower bandwidth, 2.4 mm connector: 50 gigahertz (GHz).

The same is true of mating 3.5 mm and 2.92 mm connectors, resulting in the bandwidth being reduced to 33 GHz.

Mating connectors across quality grades

The SMA connector is a production class connector, and mechanical tolerances are not as tight as instrument class connectors. A common problem is that the diameter or length of the center pin on an SMA plug may differ from those of the 3.5 mm or 2.92 mm specification; this may damage the receptacle. Mating elements that do not fit correctly will impact the electrical integrity of the interface, resulting in poor matching and reflections. Other problems include out-of-specification concentricity and poor surface finish.

Concentricity is the centering of the pin in the connector body. An out-of-tolerance, off-center pin can bend the receptacle contacts, making it unusable for subsequent mating.

The surface finish of the mating elements should be smooth with no dents, high spots, burrs, or dirt. Surface imperfections can result in poor electronic matching and signal reflections.

Simple rules to prevent damage

By following these simple rules, you can avoid costly errors:

1. Use a connector saver to protect the instrument connector. A connector saver is a coaxial plug-to-jack adaptor that is added between the instrument connector and the outside world. If the connector saver is damaged, it is easily replaced at a relatively low cost.

For 3.5 mm connectors, use a coaxial adaptor like Carlisle Interconnect Technologies’ TMA-5MS-5FS-00 3.5 mm (male) to 3.5 mm (female) coaxial adaptor (Figure 1).

Figure 1: The TMA-5MS-5FS-00 is a 3.5 mm coaxial adaptor that can be used as a connector saver to protect instrument connectors. (Image source: Carlisle Interconnect Technologies)

Figure 1: The TMA-5MS-5FS-00 is a 3.5 mm coaxial adaptor that can be used as a connector saver to protect instrument connectors. (Image source: Carlisle Interconnect Technologies)

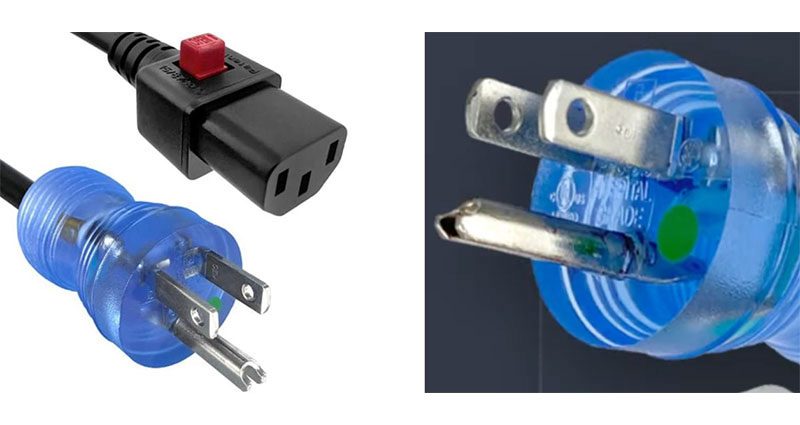

For 2.92 mm connectors, use a coaxial adaptor like P1dB Inc.’s P1AD-29MF 2.9 mm plug to 2.92 mm jack coaxial adaptor (Figure 2).

Figure 2: The P1AD-29MF adaptor can be used as a connector saver for 2.92 mm coaxial connections. (Image source: P1dB Inc.)

Figure 2: The P1AD-29MF adaptor can be used as a connector saver for 2.92 mm coaxial connections. (Image source: P1dB Inc.)

2. Inspect the SMA connector for dirt, center pin straightness, and concentric pin alignment.

3. Clean both connectors carefully using alcohol and a lint-free swab.

4. Align the center pin and receptacle and mate them gently until firmly seated.

5. Turn the connector nut by hand to engage the mated connector, being careful not to rotate the connector bodies relative to each other. Hand tighten the nut.

6. Use a torque wrench like the Copper Mountain Technologies CMT TW-S (Figure 3) to ensure the proper torque specification. If the connectors have different torque specifications, the lesser of the two should be used. Ensure that the connector bodies do not rotate while tightening.

Figure 3: A torque wrench such as the CMT TW-S can be used to ensure a correct connection. If connectors have different torque specifications, use the lesser of the two. (Image source: Copper Mountain Technologies)

Figure 3: A torque wrench such as the CMT TW-S can be used to ensure a correct connection. If connectors have different torque specifications, use the lesser of the two. (Image source: Copper Mountain Technologies)

Conclusion

Though coaxial connectors may seem compatible, it’s not always the case as there are different grades and slightly different sizes. Following the simple rules outlined above will protect the instrument connectors and guarantee good measurement quality.

Have questions or comments? Continue the conversation on TechForum, DigiKey's online community and technical resource.

Visit TechForum