How to Address the Challenges to Implementing Robust Traceability Solutions

Traceability of individual components and products throughout the supply chain is often not an option, but when possible, it can be a challenging task. If you’re involved in the design and implementation of manufacturing or supply chain systems, you can face regulatory demands, standards requirements, and legal obligations. All of these make it necessary to deploy robust traceability solutions in a variety of industries like consumer goods, automotive and medical device manufacturing, as well as food, beverage, biomedical, and pharmaceutical production and packaging.

Traceability involves marking individual components and products with unique identifiers like one-dimensional (1D) and two-dimensional (2D) barcodes that can be rapidly and automatically read. In addition to helping meet regulatory standards and legal requirements, like the Drug Supply Chain and Security Act (DSCSA) and the unique device identifier (UDI) mandate from the U.S. Food and Drug Administration (FDA), improvements in traceability can lead to higher productivity and quality. Unfortunately, in today’s high-speed production environments and packaging lines, and when products are in the field, traceability markings can become damaged. As such, a reliable way to quickly and accurately read even damaged markings is needed.

This blog reviews the requirements for traceability and the challenges of implementing robust solutions. It then presents high-performance 1D and 2D barcode readers from Omron that can rapidly read damaged bar codes to support these solutions.

Barcode reader requirements and options

Barcode formats are available for almost any need you may have related to traceability. For example, if you’re in the automotive industry supply chain, you may be responsible for implementing recalls as required by the National Highway Traffic Safety Administration (NHTSA). In this case, the Automotive Industry Action Group (AIAG) has published a Traceability Guideline.

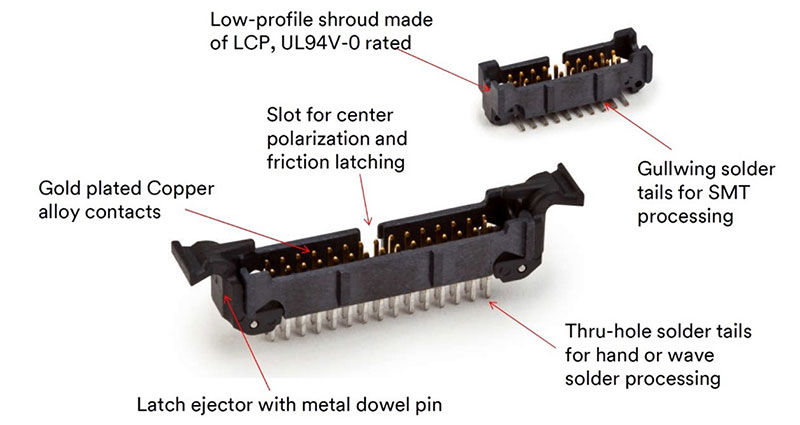

Other examples of the need for traceability include the DSCSA from the FDA which outlines steps to achieve interoperable electronic tracing of products at the package level to identify and trace certain prescription drugs throughout the distribution chain. There are also UDIs that enable the traceability of medical devices from manufacturing through distribution to patient use. Depending on the requirements, you have a wide variety of barcode formats to choose from, including 1D linear barcodes, stacked symbols, and 2D (Figure 1).

Figure 1 : Examples of barcode formats and styles (not to scale). (Image source: Omron)

Figure 1 : Examples of barcode formats and styles (not to scale). (Image source: Omron)

Making the grade and satisfying the standard

Of course, not all barcodes are created (printed) equally. There are industry-specific and international standards you need to consider when determining if a particular barcode is properly printed. Some factors included in the standards are:

- Contrast ratio between white and black areas

- Reflectance of the black bars

- Edge contrast variations between bars and spaces

- Variation or modulation of the density of the black printing across the barcode

- Defects like black spots in the white spaces or white marks in the black bars

- Accurate printing of the different widths of various bars and spaces

Testing standards are available to quantify the quality of barcode printing. The ISO standards give a quality grade to barcodes from 0 to 4.0. The best barcode is 4.0, 1.5 is usually the lower acceptable bound, and 0 is unusable. Examples of 1D and 2D print quality and symbology standards include:

- ISO/IEC 15416, 1D Print Quality Standard

- ISO/IEC 15415, 2D Print Quality Standard

- ISO/IEC 15434, Symbol Data Format Syntax

- ISO/IEC 16022, International Symbology Specification

- ISO/IEC 29158:2020, Direct Part Mark Quality Guideline

- AIAG B-4 Parts Identification and Tracking

- Clinical/Laboratory Standards Institute, AUTO2-A2 Bar Codes for Specimen Container Identification

- Electronics Industry Association, CEA-706 Component Marking

- U.S. Department of Defense, IUID MIL-STD-130 Permanent and Unique Item Identification

What’s hard about reading barcodes?

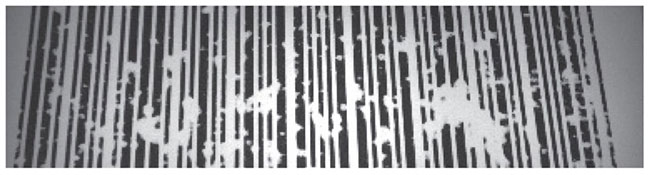

Regardless of the style and initial grade of the barcode you’re using, reading problems can crop up. Even with high-quality inks and precise printing, harsh environments and mishandling can result in the degradation of barcodes over time (Figure 2).

Figure 2: Example of a damaged barcode that some barcode readers can still decode. (Image source: Omron)

Figure 2: Example of a damaged barcode that some barcode readers can still decode. (Image source: Omron)

In addition to less than pristine barcodes, variations in lighting can make it difficult to read them. If you’re dealing with any of these issues, you can use a reader with an advanced decoding algorithm like X-Mode from Omron, which can reconstruct the discontinuous symbol data from multiple scan lines in order to retrieve information.

High-reliability barcode readers

Omron’s model V430-F000L12M-SRX includes the X-Mode decoding algorithm. It also has autofocus (75 to 1200 millimeters (mm)), a 1.2 megapixel (MP) image sensor, a wide field of view (FoV) of 23 to 417 mm, and integrated red LED lighting (Figure 3). Alternate LED configurations are available.

Figure 3: The V430-F000L12M-SRX barcode reader uses the X-Mode algorithm, has a wide FoV lens, integrated red LED lighting, and a 1.2 MP sensor. (Image source: Omron)

Figure 3: The V430-F000L12M-SRX barcode reader uses the X-Mode algorithm, has a wide FoV lens, integrated red LED lighting, and a 1.2 MP sensor. (Image source: Omron)

For less challenging applications, you can choose a reader without the X-Mode algorithm, such as Omron’s V430-F000W12M-SRP. Other models have sensors from 0.3 to 5 MP, and all have double front window construction to minimize moisture condensation in the unit. Depending on the model, connectivity options include Ethernet/IP, Ethernet TCP/IP, and PROFINET.

Conclusion

Selecting the correct barcode format is only the first step in the implementation of a robust traceability solution to satisfy regulatory demands, standards requirements, and legal necessities like product recalls. Numerous factors can make barcodes difficult to read, requiring a high-performance barcode reader that is optimized for your specific operating conditions.

Have questions or comments? Continue the conversation on TechForum, DigiKey's online community and technical resource.

Visit TechForum