What Constitutes a Heavy-Duty Connector and Where Are They Used for Industrial Connectivity

Contributed By DigiKey's North American Editors

2021-06-30

A wide array of connectors are used in industrial applications to take the electrical power, sensor signals, and control data on cables through their junctions out of and into automation components. What constitutes a heavy-duty connector (sometimes abbreviated HDC in connector product names) depends on the application … so is somewhat relative. That said, there’s a distinct difference between ruggedized industrial connectors and those light-duty RJ and IEC connectors found in clean indoor automation applications involving basic Ethernet and light power.

Heavy-duty connectors can feature greater overall robustness as well as enhanced ingress protection, reduced flammability, wide operating temperature, interlocks, earth shielding, or simply more reliable connection with positive locking.

Heavy-duty cable glands versus connectors

Cable glands (sometimes called cord grips) are mostly mechanical components that encircle cables as the latter pass through the boundaries of industrial control panels as well as other enclosures, connectors, and controller bodies made of sheet metal and hard plastic. Cable glands serve three purposes. They:

- Secure the cable

- Prevent cable chafing and other wear

- Provide a seal around the cable section to protect against moisture ingress and siphoning into the enclosure

The way cable glands anchor cables prevents damage to electrical contacts should the cable be tugged or otherwise disturbed. Cable glands also prevent the sheaths of cables from rubbing against the sharp rims of holes through the enclosure as the gland bodies fill and flare out around these edges. Without cable glands, cables subject to even the slightest movement could be quickly sliced by the sharp edges of enclosure holes until their outer insulation is completely sawn through … and the cable cores short out.

In contrast with these cable glands (that encircle cables), are connectors that terminate cables — and generally allow for more convenient disconnection and reconnection as well as joining of multiple component and cable sections. Typically, heavy-duty variations of these connectors include one or more ruggedizing features.

Heavy-duty cable connectors can feature cable-entry protection in the form of a universal cable gland, cable clamp, or seal and anti-twist device. No matter the mechanical form, these secure the cable and prevent it from pulling out of terminals. Cable-entry protection can also prevent cable wear just as standalone cable glands do. Note that lamellar inserts (glands with multiple fingers) are common on moderately ruggedized connectors, though the inserts require regular retightening to ensure ingress protection. Glands with a continuous seal that clamps around the cable are often a more reliable choice for heavy-duty applications.

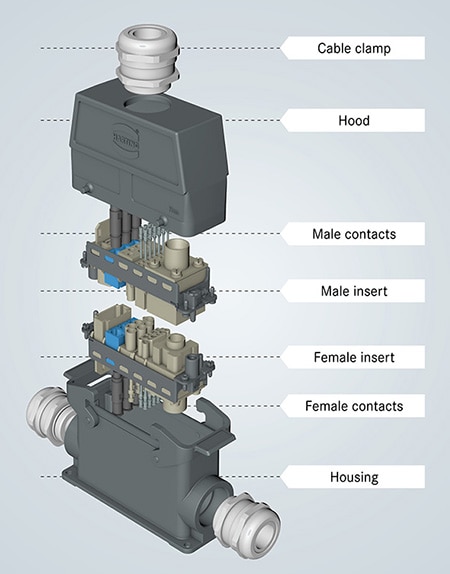

The hood on some heavy-duty cable connectors encloses the electrical conductors of the plug while providing insulation and ingress protection — as well as some locking or latching sleeve or lever to keep the connector halves together.

On many heavy-duty cable connectors, the male insert includes male pins as well as screws or crimp terminals where the conducting wire cores contact the pins. In such connectors, the female insert includes complementary sockets as well as receptacles or crimp terminals where the conducting wire cores contact the sockets.

The ruggedized housings of heavy-duty cable connectors are perhaps their most conspicuous feature — often including insulation and ingress protection. Accessories may include additional protective covers and guides for pin codes.

Figure 1: Han®-series connectors include several complementary features to withstand fairly brutal environmental conditions. (Image source: Harting)

Figure 1: Han®-series connectors include several complementary features to withstand fairly brutal environmental conditions. (Image source: Harting)

IP codes for ingress protection in heavy-duty connectors

It’s also fairly standard for heavy-duty connectors to provide ingress protection against fluids and solid particles. The ingress protection of connectors is rated using the same Ingress Protection (IP) codes as used for enclosures. The first digit of an IP code denotes protection from solid objects, with values ranging from 0 (indicating no protection) to 6 — indicating a fully dust-tight build. The second IP-code digit indicates protection against fluids, with values ranging from 0 (for no protection) to 8 (for continuous protection against water at a depth of 1 m) or even 9K — indicating protection against high-pressure jets. For example, an IP67-rated connector resists penetration of dust and temporary immersion in water.

Proprietary connector variations — why so common?

Due to the strong reliance of heavy-duty connectors on mechanical closure and gasketing features, many options on the market today are either proprietary designs or application-specific connector variations. For example, whole industries have standardized on the heavy-duty rectangular connectors for power and control connections from the Harting Han series. In fact, this trademarked connector brand is sometimes considered synonymous with the term heavy-duty connector in general.

Figure 2: Han-series connectors (with four and 26 pins) are somewhat of an industry standard — satisfying various data and power-connectivity requirements from 50 to 5,000 V and 3 to 200 A. Locking arrangements include a single-lever Han-Easy Lock for easy single-handed operation and a double-lever Han-Easy Lock — for more reliable locking, higher pressure tightness, and use with cable-to-cable connections. Yet another rugged option is screw locking for maximum pressure tightness and reduced risk of unauthorized use. (Image source: Harting)

Figure 2: Han-series connectors (with four and 26 pins) are somewhat of an industry standard — satisfying various data and power-connectivity requirements from 50 to 5,000 V and 3 to 200 A. Locking arrangements include a single-lever Han-Easy Lock for easy single-handed operation and a double-lever Han-Easy Lock — for more reliable locking, higher pressure tightness, and use with cable-to-cable connections. Yet another rugged option is screw locking for maximum pressure tightness and reduced risk of unauthorized use. (Image source: Harting)

Han-series connectors have pins arranged within a rectangular hood that mate with corresponding sockets within a rectangular housing. The connectors are generally equipped with locking levers to let installation personnel easily and securely close the connector — ensuring that it can’t be pulled apart … even when considerable tension loads are applied.

Hoods (bolt-on connector cover shells) are most common on power-cable terminations; they’re available in top-entry and side-entry configurations. Housings may be screw mounted, surface mounted, or bulkhead mounted to provide a connection on instrumentation or machinery. Alternatively, housings can also terminate cables for cable-to-cable connections. Hoods and housings are typically produced from die-cast alloy … but stainless steel and plastic housings are also common. Some manufacturers offer configurable connectors that can be ganged inside a single hood or housing. This can allow higher pin counts across all distinct modules. Such connectors are available under the Molex GWconnect HDC and TE Connectivity HDC brands.

The ruggedized cable connectors for data and sensor-signal cables are slightly different. Here, M-series connectors lead. They’re robust connectors that serve in various data connections (including those based on Ethernet) as well as electrical power transmissions. Rugged M-series connectors are most common in industrial networking applications involving PROFINET, fieldbus, and industrial Ethernet to connect sensors, switches, and PLCs.

As covered in previous DigiKey articles, M-series connectors consist of round male and female connectors having standard metric-threaded sleeves encasing and protecting internal pins and receptacles. Standard sizes include 5-mm M5, 8-mm M8, 12-mm M12, 16-mm M16, and 23-mm M23 connectors. The threaded sleeve provides a very robust and reliable connection which cannot be easily pulled apart and which ensures a very reliable electrical connection, minimizing intermittent signals. The sleeve also gives M-series connectors a high level of ingress protection which can, in many cases, even enable use in washdown and corrosive environments. The most common sizes are M8 and M12 connectors, with two, three, four, five, eight, or 12 pins. Typically, three or four-pin M-series connectors service sensors and power supplies; four or eight-pin M-series connectors service Ethernet and PROFINET devices; and four or five-pin M-series connectors service Fieldbus, CAN bus, and DeviceNet automation devices.

Figure 3: M-series connectors are made of high-strength aluminum and feature a ratchet screw for quick and secure cable coupling with one hand. (Image source: LEMO)

Figure 3: M-series connectors are made of high-strength aluminum and feature a ratchet screw for quick and secure cable coupling with one hand. (Image source: LEMO)

Data connections used in industrial applications include Ethernet, ModbusTCP/IP, EtherCAT, Ethernet/IP, and Profinet … as well various proprietary formats. RJ connectors are the standard for all implementations of Ethernet — but don’t provide ingress protection and aren’t particularly robust. Although a male-side plastic tab clicks into the socket (to hold the connector halves together) it’s rather delicate … and lets plugs pull from their sockets with even moderate tugging. That’s why M-series connectors are a superior option if an automated installation is subject to motion and incidental abuse.

There’s yet another caveat here, though. While standard M-series connectors are a suitable option for industrial connectors, obtaining a reliable connection (and rated ingress-protection level) depends on the technician correctly tightening the connector thread. Some connector suppliers have aimed to address even this potential failure point by selling push-fit connectors that automatically lock. Perhaps the most established of these is the Molex Brad series of connectors, which are a direct replacement for standard M12 connectors. These omit the threaded sleeve for a reliable push-to-lock mechanism … so simply pressing the connector halves together ensures perfect locking and a reliable connection without risk of intermittent signals or disconnection. These connectors are available in various configurations and include push-on and pull-off connectors with IP65 protection.

Figure 4: Ultra-Lock connectors are a push to lock option with O-rings to provide foolproof connections and IP69K ingress protection. (Image source: MOLEX)

Figure 4: Ultra-Lock connectors are a push to lock option with O-rings to provide foolproof connections and IP69K ingress protection. (Image source: MOLEX)

When used for Ethernet applications, M-series and Molex Brad connectors can also carry power using the Power over Ethernet (PoE) standards in three configurations — Alternative A, Alternative B, and 4PPoE — to support varying levels of bandwidth and power capacity.

IEC power connectors for high-power requirements

The International Electrotechnical Commission (IEC) defines various standards for power connectors used in domestic, commercial, and industrial applications. For example, IEC 60320 covers non-locking connectors with voltages and currents up to 250 V and 16 A respectively. These include large but nonruggedized C13/C14 as well as larger C19/C20 couplers common on electronic equipment for industrial applications — including computer power supplies and server enclosures. These couplers aren’t normally considered heavy-duty connectors.

In contrast, IEC 60309 locking connectors are ruggedized — and intended for use on industrial cables that transmit voltages and currents up to 1,000 V and 800 A respectively. All IEC 60309 locking connectors provide some degree of ingress protection with standard configurations proving splashproof IP44, waterproof IP67, or jet proof and waterproof IP66/67 protection.

The standard also allows for interlocked socket outlets: Connectors with this feature don’t allow energization unless mated with a plug … and the plug can’t be removed until the power is switched off. The following color coding indicates the allowable voltage and frequency range for the connector.

- Yellow indicates the IEC 60309 power connector is suitable for carrying 100 to 130 V at 50 or 60 Hz.

- Blue indicates the IEC 60309 power connector is suitable for carrying 200 to 250 V at 50 or 60 Hz.

- Red indicates the IEC 60309 power connector is suitable for carrying 380 to 480 V at 50 or 60 Hz … often in a three-phase configuration.

Figure 5: This red color-coded heavy-duty connector satisfies the IEC 60309 standard for supplying 380 to 480 V. (Image source: Wikimedia Commons)

Figure 5: This red color-coded heavy-duty connector satisfies the IEC 60309 standard for supplying 380 to 480 V. (Image source: Wikimedia Commons)

Conclusion

Heavy-duty connectors must satisfy various requirements. Will the connector need to resist crushing from impact loads — or being pulled apart? Is ingress protection against dust or water needed? What temperatures will the connector need to withstand? Will the heavy-duty connector be installed in settings where flammability is a concern?

The number of pins and the voltage and current to be carried by each must also be considered — along with the direction of cable entry and level of cable protection. On automated machines that subject the cables and their connectors to movement, suitable glands, and cable clamps must be provided … and anti-twist devices may also be prudent.

For electrical loads that are relatively light but operating in harsh environments, M-series connectors and their derivatives are often suitable choices. For higher electrical loads, rectangular connectors may be better a better solution … especially as they can be configured to suit just about any complex requirement with various cable-entry directions, mounting options, and generally modular builds. Otherwise, for simple power connections to a single or three-phase ac supply, IEC 60309 locking industrial connectors are the leading (if not the only) choice.

Disclaimer: The opinions, beliefs, and viewpoints expressed by the various authors and/or forum participants on this website do not necessarily reflect the opinions, beliefs, and viewpoints of DigiKey or official policies of DigiKey.