Simplify Industrial Equipment Deployment Using Configurable Modular Connectors

Contributed By DigiKey's North American Editors

2020-12-15

When considering how to make signal and power connections for industrial applications, there are generally many power, ground, and signal connections that must be made in tight settings. Designers need to specify cabling of many types, while interconnect preparation time, convenience, and space are also critical factors. In these situations, many industrial equipment designs resort to basic point-to-point “hardwiring” where the technician manually connects the wires one at a time.

The reality, however, is that this manual on-site hardwiring is very time consuming in the field, prone to error, and therefore costly. It is especially costly in lost time, restoration effort, and errors if a disconnect/reconnect is needed for any reason including repair, expansion, or rearrangement.

The solution to this efficiency, cost, space, and reliability problem is to use modular connectors as they are flexible, versatile, and easily managed. They can also come with a large variety of connector housings and mounting frames that are paired with designer-selectable mix-and-match inserts designed to handle a diverse range of specific electrical signals—including power, signal and data types—using bare wires, D-Sub connectors, coaxial cabling, and even optical fiber and compressed-air pneumatics.

This article will use a practical example to highlight some of the issues with a manual approach. It will then introduce a more flexible and efficient approach based on the Han-Modular series connectors from HARTING, showing also how they solve many wiring problems. An accompanying Configurator Tool to help designers quickly build the optimum connector based on the Han-Modular system will be described.

Point-to-point hardwiring: quick, easy, often messy

It seems easier to implement basic interconnections with point-to-point hardwiring, but in many instances that decision is regretted. Consider the example of an upgrade to the wiring of a simple one-zone “dumb” thermostat which required an intermediate relay between the smart unit and the heating-system controller, to a smart one. The wiring of that first zone was haphazard and looked messy but was quick to install and worked. Also, since it was all 24 volts AC, there were no issues with exposed wiring and safety.

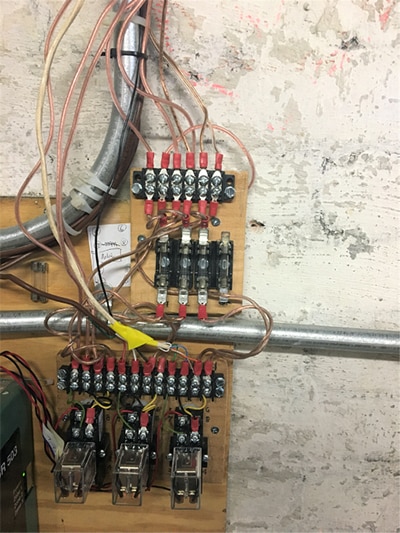

However, the following year, the homeowner decided to upgrade the two other heating zones to smart thermostats. The added point-to-point wiring was also done “on the quick” and the result was a rat’s nest which amazingly worked (Figure 1). While functional, this is not a good long-term approach, as this scheme would be very difficult to troubleshoot later if a problem arose, and any additional upgrades would be a nightmare.

Figure 1: Messy point-to-point hardwiring can be the result of project complexity or even incremental layering of added functionality to a base system, as shown by this wiring for the relays for a three-zone smart thermostat upgrade. (Image source: Bill Schweber)

Figure 1: Messy point-to-point hardwiring can be the result of project complexity or even incremental layering of added functionality to a base system, as shown by this wiring for the relays for a three-zone smart thermostat upgrade. (Image source: Bill Schweber)

This situation was unacceptable for practical, esthetic, and documentation reasons, so the decision was made to clean up and rewire the entire arrangement by hardwiring with spade lugs and screw terminal strips (Figure 2). This took less time and planning than using three dedicated connectors (one per zone) and was viewed as an acceptable compromise in this case, despite over 50 discrete connections. This installation demonstrated the apparent benefits of hardwired point-to-point connections: they require relatively little planning (a schematic or interconnect diagram is often enough), minimal commitment, and can be started immediately.

Figure 2: The thermostat upgrade wiring was improved by re-wiring with extensive use of spade lugs and screw terminal strips, but still required extreme care when re-wiring over 50 connections to avoid mistakes while taking up significant space compared to using multicontact connectors. (Image source: Bill Schweber)

Figure 2: The thermostat upgrade wiring was improved by re-wiring with extensive use of spade lugs and screw terminal strips, but still required extreme care when re-wiring over 50 connections to avoid mistakes while taking up significant space compared to using multicontact connectors. (Image source: Bill Schweber)

Industrial world is more complex

In an industrial setting, even that improved wiring would have detrimental long-term implications. Installing all those individual wires requires multiple checks on each wire’s placement versus the drawing, as well as checking physical integrity. Labeling of each wire is also critical, and there are usually ANSI and ISO labeling standards to follow. If the equipment needs to be disconnected for repair or relocation, the complicated connection process must be undone, and its reconnection requires repeating the process.

Obviously, discrete pre-wired cables and mating connectors offer an initially attractive alternative. These can be built and tested in advance in a controlled setting while eliminating hardwiring, but also bring new concerns. Many installations employ a mix of signal types such as low and high voltages over a range of current ratings, sensor signals, numerous types of data links, as well as Ethernet, optical fiber, and even low-pressure air (pneumatic). The result is a varied collection of cables and connectors, which take up considerable panel space, may require keying if there are several cables with the same connector type, and still take time to connect/disconnect.

There is a solution which seems to solve the multi-cable/connector dilemma, at least at first. Standard connectors are available with multiple power and signal contacts in a common housing. These are really only a partial solution for two reasons. First, they are available only in pre-determined, fixed sets of contact numbers and types, such as two positions for power and six for signal. Second, they are only available for basic low/high level signal and power levels, and some data signals, but not for gigabit Ethernet (GbE), glass or plastic optical fiber, or even low-pressure pneumatic (air) connections.

Full modularity: a better solution

To get around these contact constraints, designers can use the HARTING Han-Modular series of connectors. These represent the state-of-the art in terms of mix-and-match flexibility due to the number and types of contacts. The designer selects almost any combination of connectors and contacts, and then picks a connector frame to hold them along with a suitable housing (Figure 3 and Figure 4).

Figure 3: User-defined modularity results in creation of a custom connector with standard components. (Image source: HARTING)

Figure 3: User-defined modularity results in creation of a custom connector with standard components. (Image source: HARTING)

Figure 4: The result from the process shown in Figure 3 is a compact, fully customized, enclosed connector assembly with matched mating sides. (Image source: HARTING)

Figure 4: The result from the process shown in Figure 3 is a compact, fully customized, enclosed connector assembly with matched mating sides. (Image source: HARTING)

The Han modules support connectors and contacts (male and female) for currents from a few milliamps to 200 amperes (A), voltages up to 5,000 volts, pneumatic hosing, data lines, shielded bus signal, and even plastic or glass optical fiber cables. That’s an electrical and mechanical selection range not found in other multifunction connector/contact assemblies.

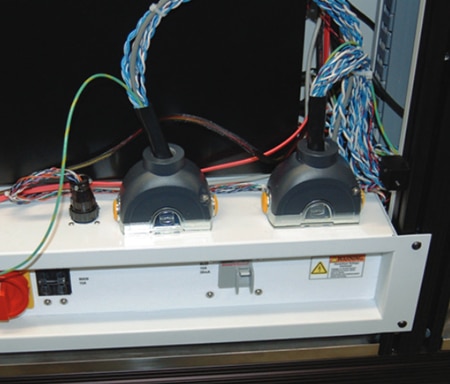

Using these connectors makes the cable and wiring a pre-engineered task that can be designed, assembled, and tested as a complete harness off-site rather than at the installation site, then simply and quickly connected and disconnected (Figure 5).

Figure 5: Connector-terminated cables are assembled and tested off-site, then quickly installed on site and disconnected as needed; note the different types of wiring merged within each of the two rectangular connectors, particularly visible in the connector on the left. (Image source: HARTING)

Figure 5: Connector-terminated cables are assembled and tested off-site, then quickly installed on site and disconnected as needed; note the different types of wiring merged within each of the two rectangular connectors, particularly visible in the connector on the left. (Image source: HARTING)

There’s another benefit to the high degree of modularity and flexibility of this series. In the real world of product design, requirements change and evolve as the project proceeds. With the Han-Modular series, there’s no need to start over again in searching for a connector or connectors that can accommodate these added requirements; all a designer has to do is add another internal module to the basic connector.

Examples highlight the range and versatility

Rather than call out the many connectors and contacts which are available in the Han-Modular series, a brief look at some provides a good sense of the options.

First, there’s the frame which holds the connector modules. One example is the 09140240313 heavy-duty hinged frame for six modules (Figure 6). The individual connection modules are inserted, secured, and locked into this frame.

Figure 6: One of the many available frames for holding the connector inserts, the 09140240313 heavy-duty hinged frame, has space for six such modules. (Image source: HARTING)

Figure 6: One of the many available frames for holding the connector inserts, the 09140240313 heavy-duty hinged frame, has space for six such modules. (Image source: HARTING)

A state-of-the-art industrial system may even need to support GbE links, so the 09140083012 gigabit module with male contacts can be added (Figure 7). The shielded connector is rated to 10 gigabits per second (Gbit/s) operation and also supports IEEE 802.3bt (also called PoE++) power delivery.

Figure 7: This shielded 09140083012 GbE connector in the series is rated to 10 Gbit/s operation and also supports IEEE 802.3bt (PoE++) power delivery. (Image source: HARTING)

Figure 7: This shielded 09140083012 GbE connector in the series is rated to 10 Gbit/s operation and also supports IEEE 802.3bt (PoE++) power delivery. (Image source: HARTING)

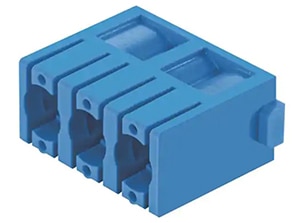

At the same time, the connector may need to support substantial AC or DC power, so the 09332062648 six-contact female housing for press inserts may be a good choice (Figure 8). It can handle press inserts rated to 500 volts at 16 A using solid or stranded wire in sizes from 0.14 millimeters square (mm²) to 2.5 mm² (AWG 26 to AWG 14).

Figure 8: Industrial installations usually require substantial amounts of AC and DC power, which can be connected via this 09332062648 six-contact female housing for press inserts; it handles a wide range of solid and stranded wire sizes. (Image source: HARTING)

Figure 8: Industrial installations usually require substantial amounts of AC and DC power, which can be connected via this 09332062648 six-contact female housing for press inserts; it handles a wide range of solid and stranded wire sizes. (Image source: HARTING)

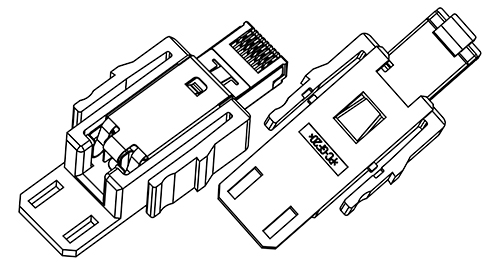

For installations where an industry-standard RJ45 Cat 6A 8-position modular plug is needed, the 09454001520 connector is available (Figure 9).

Figure 9: The Han-Modular system also has provision for the widely used RJ45 connector, using the 09454001520 connector. (Image source: HARTING)

Figure 9: The Han-Modular system also has provision for the widely used RJ45 connector, using the 09454001520 connector. (Image source: HARTING)

One of the distinguishing features of the Han-Modular system is its ability to easily provide low-pressure air (pneumatic) connections in addition to its wide array of electrical connection options. For example, the 09140033501 is a pneumatic module which is compatible with the many frames, and can be configured for low-pressure lines of various diameters as set by the selection of suitable inserts (Figure 10). Among these are the 09140006304 male metal insert (Figure 11) and the complementary 09140006404 female metal insert (Figure 12), both for 4 mm inside diameter (ID) tubing.

Figure 10: The Han modules go beyond connecting electrical-only signals, data, and power by accommodating pneumatic control using modules such as the 09140033501 for low-pressure air connections and suitable inserts. (Image source: HARTING)

Figure 10: The Han modules go beyond connecting electrical-only signals, data, and power by accommodating pneumatic control using modules such as the 09140033501 for low-pressure air connections and suitable inserts. (Image source: HARTING)

Figure 11: The 09140006304 male metal insert is designed for pneumatic tubing with an inside diameter of 4 mm. (Image source: HARTING)

Figure 11: The 09140006304 male metal insert is designed for pneumatic tubing with an inside diameter of 4 mm. (Image source: HARTING)

Figure 12: The 09140006404 metal insert is the female connector for low-pressure air, also for tubing with a 4 mm ID. (Image source: HARTING)

Figure 12: The 09140006404 metal insert is the female connector for low-pressure air, also for tubing with a 4 mm ID. (Image source: HARTING)

Again, these are just a very tiny sampling of the many available inserts and connectors in the Han-Modular series.

Configurator Tool is key to ease of use

While the Han-Modular series is useful when connecting a diverse array of wire types, functions, and sizes, the choices can be overwhelming and seemingly impossible to configure optimally. HARTING addresses this by providing the free Han Configurator Tool.

This online tool greatly simplifies the process of building a customized Han-Modular connector for specific applications. The designer simply enters the details of the connection requirements and the tool calls out the best-fit modular inserts for the application, while it also provides technical details, 3D drawings, and data files for many different connector options. The tool also acknowledges that there are designers who are already familiar with the Han system, and allows them to configure an entire interface directly without going through the assistant step-by-step.

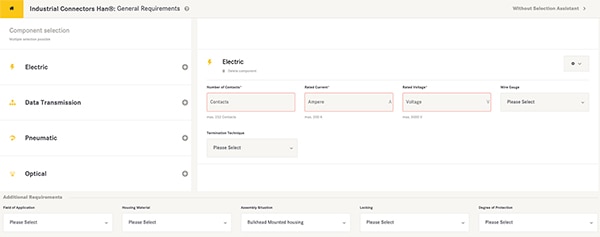

Using the Configurator Tool begins with identifying the first signal type to be terminated (Figure 13).

Figure 13: The Configurator Tool shows a listing of the many basic connection types supported by the Han-Modular system; designers begin by picking one of the several types they want to build into the connector assembly. (Image source: HARTING)

Figure 13: The Configurator Tool shows a listing of the many basic connection types supported by the Han-Modular system; designers begin by picking one of the several types they want to build into the connector assembly. (Image source: HARTING)

The tool responds with pull-down boxes for relevant specific data, shown here for electric signals: number of contacts, current rating, voltage rating, wire gauge, and termination technique. Different data sets are shown according to the signal type (Figure 14).

Figure 14: Next, the Configuration Tool asks the designer to specify the top-tier parameters for that signal type; shown here is the choice of “Electric”. (Image source: HARTING)

Figure 14: Next, the Configuration Tool asks the designer to specify the top-tier parameters for that signal type; shown here is the choice of “Electric”. (Image source: HARTING)

Next, pull-down/up menus allow the designer to specify additional requirements such as Housing Material (Figure 15), Assembly Situation (Figure 16), and Locking Type (Figure 17), again appropriate to the available connectors (shown here for “Electric”).

Figure 15: The bottom of the starting screen asks for the designer’s preference for Housing Material. (Image source: HARTING)

Figure 15: The bottom of the starting screen asks for the designer’s preference for Housing Material. (Image source: HARTING)

Figure 16: The bottom of the starting screen also offers a selection for Assembly Situation for the selected connector. (Image source: HARTING)

Figure 16: The bottom of the starting screen also offers a selection for Assembly Situation for the selected connector. (Image source: HARTING)

Figure 17: Another choice to be made is the required connector locking mechanism. (Image source: HARTING)

Figure 17: Another choice to be made is the required connector locking mechanism. (Image source: HARTING)

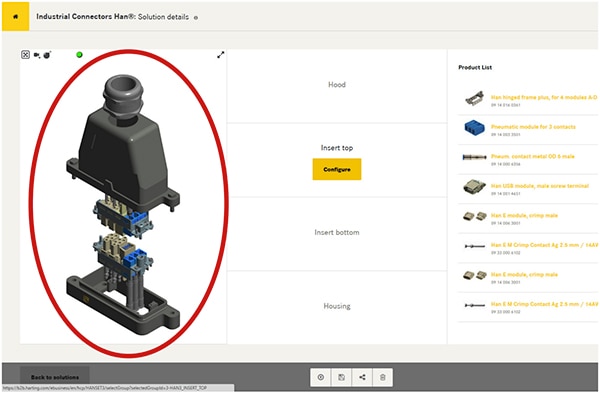

The tool then generates a first feasible possible solution along with other suggested solutions, with the configuration displayed as a 3D model along with the product list (Figure 18).

Figure 18: Once all the needed connection types, parameters, and preferences are entered, the tool builds the complete connector assembly and provides a detailed 3D image, parts listing, and all other needed information. (Image source: HARTING)

Figure 18: Once all the needed connection types, parameters, and preferences are entered, the tool builds the complete connector assembly and provides a detailed 3D image, parts listing, and all other needed information. (Image source: HARTING)

The designer can select the preferred configuration or can modify the suggested solutions and replace individual components.

The Han configurator enhances and speeds all aspects of design process, since the connector-specifying engineer can accomplish multiple objectives:

- Explore connector design with an interactive 3D visualization

- Ensure that the solution is viable

- Easily collaborate with other team members

- Save and share the custom connector file

- Download standard CAD STP files and data sheets

- Automatically create a detailed bill of materials (BOM)

Conclusion

The challenges of choosing the right set of connectors to terminate a cable in an industrial setting can be frustrating. The HARTING Han-Modular system simplifies getting to an optimum solution due to their high degree of flexibility, modularity, and configurability, all supported by a powerful, intuitive Configurator Tool. As a result, the hardwired point-to-point approach can be replaced by an optimized, customized solution which offers convenience and ease of connection in minimal space.

Disclaimer: The opinions, beliefs, and viewpoints expressed by the various authors and/or forum participants on this website do not necessarily reflect the opinions, beliefs, and viewpoints of DigiKey or official policies of DigiKey.