How to Save Connector Space While Preserving Flexibility in Harsh Industrial Environments

Contributed By DigiKey's North American Editors

2022-12-22

In the industrial environment, devices that are wired are challenging to replace or upgrade because it is difficult to remove and reinstall wires and cables reliably. Similarly, adding new sensors, a processor, or other components, often requires complete replacement and rewiring.

In addition, the sizes of industrial devices keep getting smaller, limiting available space for multiple connectors. At the same time, an efficient layout for good panel density requires smaller connectors that allow a combination of multiple types of connections within a single connector.

The industrial environment poses its own challenges when it comes to maintaining the integrity of devices: it’s important to keep liquids and dust from gaining access and damaging delicate components.

Connectorization—replacing hardwired devices with modular connectors—resolves all of these problems. These connectors, available in compact forms, allow the combination of multiple wiring types into a single connector. In modular form, these connectors can quickly be reconfigured to accommodate modifications and updates without requiring device or cable replacement. Also, environmentally hardened modular connectors seal out dust and liquids, as well as the impact of high-pressure water jets used for sterilization.

This article examines the basics of modular connectors, showing how they are chosen, assembled, and utilized. Along the way, it introduces exemplary connectors from HARTING that designers can use for their next industrial system design.

Connectorization using modular connectors

There are two ways to wire power, signals, and digital data into an industrial device or application.

The cabling can be either permanently hardwired, or it can be installed using a connector. The choice depends on a couple of factors. Probably the most important is how frequently the device will be disconnected and require reconnection. If the hardwired device must be reconnected, each wire needs to be carefully removed and reconnected, resulting in substantial labor costs. The chance for miswiring is high, and it can take hours of troubleshooting to repair an error.

Using connectors may initially cost more, but once that decision is made, rewiring becomes a plug-and-play scenario where it is difficult to miswire, reducing the need for skilled labor. So, using connectors to replace hardwired cables—called connectorization—offers many long-term benefits.

If modular connectors are used, it increases the flexibility of the installation. Consider a modular connector that can handle power, sensors, analog and digital signals, and even pneumatics (Figure 1). There are a wide variety of modules available. The example shows an RJ45 and a USB serial data bus, three multi-pin modules with a range of pin diameters, and a module with triple pneumatic lines.

Figure 1: A modular connector can handle signals, power, digital communication interfaces, and even pneumatics, all in a single connector. The modules can be quickly and easily changed as required. (Image source: HARTING)

Figure 1: A modular connector can handle signals, power, digital communication interfaces, and even pneumatics, all in a single connector. The modules can be quickly and easily changed as required. (Image source: HARTING)

Modular connector configuration

There is a simple nomenclature of the various components of a modular connector shown in Figure 2.

Figure 2: The nomenclature of the HARTING modular connector components. The frames retain the modules and fit within the housing or hood. The connectors can be opened easily, and modules rearranged, added, or deleted for any required modifications. (Image source: HARTING)

Figure 2: The nomenclature of the HARTING modular connector components. The frames retain the modules and fit within the housing or hood. The connectors can be opened easily, and modules rearranged, added, or deleted for any required modifications. (Image source: HARTING)

The fixed portion of a base connector is a housing. The mating end of the mobile part is a hood. Frames fit within the housing or hood and serve to lock the modules in place. Connectors can be configured with extra space for future expansion by using dummy modules. The two mating connectors are fastened together using a screw or latching lever lock. Hoods can have top, multiple top, side, or multiple side cable access. The housing can be accessed from either the top or bottom.

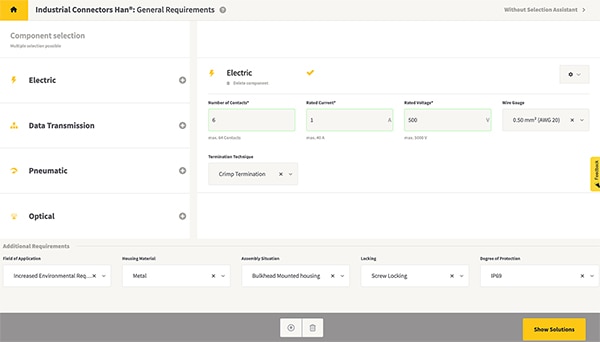

Given the large number of available modules, housings, hoods, and other connector elements HARTING provides, it can be a complex undertaking to select the right options. HARTING simplifies this process with an online configurator that makes it easy to select and design a modular connector (Figure 3).

Figure 3: The HARTING Han online configurator user interface simplifies the design and selection of modular connector components. (Image source: HARTING)

Figure 3: The HARTING Han online configurator user interface simplifies the design and selection of modular connector components. (Image source: HARTING)

The configurator guides the designer in the selection of wire, data, optical, and pneumatic elements for the connector. Each element presents choices for the user to match with the intended design.

In this example, the electrical elements are chosen. The user enters the number and types of wire media, the current-carrying requirements, and a few other design related questions. The configurator quickly shows a few possible configurations, listing the parts while also providing an isometric drawing of the assembly (Figure 4).

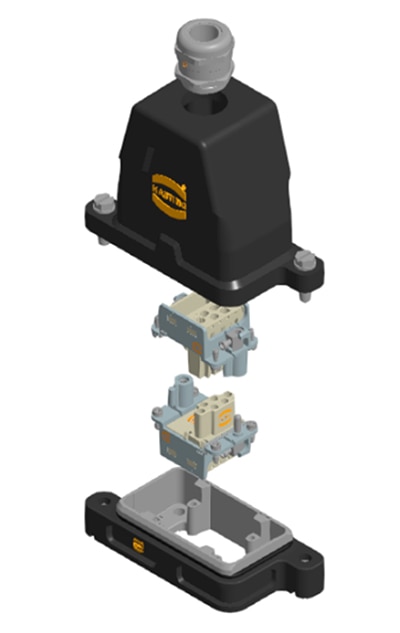

Figure 4: A configurator rendering of a six-pin wire plug and base receptacle, along with its associated base, hood, and cable clamp. (Image source: HARTING)

Figure 4: A configurator rendering of a six-pin wire plug and base receptacle, along with its associated base, hood, and cable clamp. (Image source: HARTING)

The design is fully documented with downloadable parts lists, 3D models, data sheets, type sheets, and product declarations.

In the example shown, the questions included the type of base, desired lock, the number of conductors, maximum current and voltage levels expected, and the environment. The resultant configurations included the HARTING 09400060311 panel-mounted base. The base is diecast aluminum using screw lock and is rated for harsh environments. This base was mated with a HARTING 09140060371 dual module, hinged, heavy-duty retaining frame. This frame has space for two modules. The module chosen was a six-position female module, the HARTING 09140063101. The associated silver crimp pin sockets are the HARTING 09330006220 for 20 AWG wire.

The cable side of the connector is based on the diecast aluminum HARTING 19400060411 connector hood with its associated HARTING 09140060361 heavy-duty, dual-module retaining frame. This frame accepts the HARTING 09140063001 male module with HARTING 09330006121 20 AWG silver crimp pins. The hood assembly is topped off with a HARTING 19000005090 brass cable 9-16 clamp. The base and hood accommodate two modules, so any unused positions can be filled with dummy modules, such as the HARTING 09140009950.

Environmental protection

All of the HARTING Han HPR components operate over a temperature range of -40°C to +125°C and are sealed and environmentally rated at up to IP68 and IP69K.

The ingress protection (IP) ratings, defined under IEC 60529, express the degree of protection that the connectors’ components offer from external effects. External effects include mechanical shock, foreign bodies, humidity, dust, and liquids like water, fuel, cleaning fluids, coolants, and oils.

The first number in the IP rating is the resistance to solids. The rating can vary from 0 to 6. The number 6 represents the highest level of protection. Connectors with a 6 rating are dust tight and offer full protection against solid particulates. The second number in the IP rating is the resistance to liquids. This number ranges from 0 to 9. A rating of 8 means the device is watertight and protected from water pressure. The 9K rating indicates protection from steam jet pressure cleaners and similar pressure-driven liquids. Therefore, a rating of IP68 or IP69K is excellent.

The HARTING Han HPR series is intended for harsh outdoor environments. The diecast aluminum hoods and housings have an epoxy powder-coated finish giving them excellent corrosion resistance, while also being well-sealed against wet conditions. The metal components provide excellent electromagnetic compatibility characteristics.

For multiple installations using the same connectors, this series of connectors offers up to sixteen coded keying positions to assure correct cable mating. Additionally, the HPR compact series saves space and reduces weight by being up to 25% lighter than corresponding HPR standard connectors.

Conclusion

Ensuring connection integrity, flexibility, and expandability—while conforming to form-factor requirements and the rigors of industrial environments—can be challenging for designers. As shown, connectorization based on a highly configurable, compact and modular approach, with an easy-to-use online connector element selection tool, greatly simplifies the process.

Disclaimer: The opinions, beliefs, and viewpoints expressed by the various authors and/or forum participants on this website do not necessarily reflect the opinions, beliefs, and viewpoints of DigiKey or official policies of DigiKey.