Use Application-Specific ICs to Simplify Automotive Door Electronics Design

Contributed By DigiKey's North American Editors

2020-04-29

By 2030, electronics will make up 50 percent of the cost of a vehicle, with one growth area for electronic content being the car door. Designing door electronics is a challenge; each door requires a controller, a controller area network (CAN), or local interconnect network (LIN) transceivers to connect to the rest of the vehicle’s systems, multiple motor drivers, and voltage regulators. These devices and networks can get complex, costly, weighty, and time-consuming to design in, so designers are looking for ways to simplify applications and streamline the bill of materials (BOM).

Application-specific standard products (ASSPs) designed for automotive applications ease the designer’s task. In addition, these solutions enable the designer to take advantage of either a centralized or decentralized approach to door electronics depending on the complexity of the design and cost constraints.

This article describes the evolution of networked door electronic systems and explains the respective advantages and drawbacks of the centralized and decentralized approaches. The article then explores how to use ASSPs to ease the design of a single body control unit (BCU) for a centralized design, or individual BCUs for each door in the decentralized approach. The article will also consider how these approaches integrate into the car’s in-vehicle network (IVN) via CAN and LIN solutions. Solutions from ON Semiconductor will be used by way of example.

The evolution of automotive electronics and networking functions

Automotive electronics got started with the need for engine control units (ECU) to manage fuel injection as these began to replace carburetors in the 70s. Since then, electronics have proliferated. Now a premium vehicle boasts comprehensive electronic systems for four key areas:

- The powertrain (engine control, transmission control, starter/alternator)

- Body and comfort (lighting, HVAC, seat and door, remote keyless entry)

- Safety (ABS, power steering, airbag, driver assist)

- Infotainment (navigation, audio, multimedia, cellular connectivity, Bluetooth, telematics, dashboard)

Each of these systems uses dedicated computing modules with the individual modules linked via an IVN based on CAN and/or LIN technology.

CAN is a vehicle bus standard designed to allow computing modules and sensors/actuators to communicate without the need for a host computer. It prioritizes the connections so if more than one device transmits simultaneously, the most important takes priority to avoid contention issues and ensure critical functions are not delayed. CAN is too expensive to use for connection of every electronic component in a vehicle, so it is often complemented by LIN—which uses a less complex and lower cost serial link technology for non-time-critical functions usually related to passenger comfort—to add all devices to the IVN.

This article focuses on the electronic systems associated with the door of a vehicle. Like other areas of the car, this has seen increasing use of electronics for driver convenience.

Most contemporary cars have electronically-controlled windows, locks and mirrors, and more recently, features such as pinch protection are being introduced. Luxury vehicles feature door mirror defrosting, mirror-mounted indicators, and door interior lighting. Next generation high-end models will include electrochromic mirror control that darkens the wing mirror depending on the brightness of the lights of other traffic.

Decentralized vs. centralized automotive electronics control

A centralized topology for door electronics is currently the most common approach, particularly for lower cost vehicles with limited door functionality. The BCU—a module comprising INV systems, a microprocessor, actuator drivers and discrete components—is connected to the actuators in each door by wiring carrying power, and separate wiring for CAN or LIN communication. The key advantages of this approach are cost (only one BCU is needed) and scalability (Figure 1).

Figure 1: A centralized door electronics system saves costs by using a single BCU. (Image source: ON Semiconductor)

Figure 1: A centralized door electronics system saves costs by using a single BCU. (Image source: ON Semiconductor)

However, the centralized topology is falling out of favor for premium vehicles because they require a much greater level of functionality, which in turn requires more wiring. As a result, the wiring harnesses become heavy, complex and expensive.

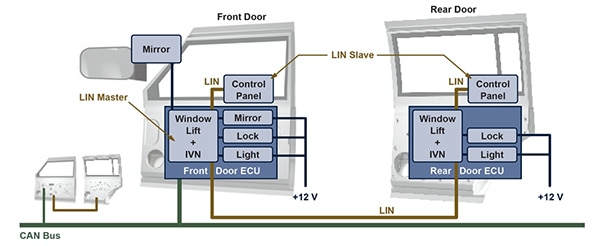

The alternative is the decentralized approach, whereby each door has its own BCU. In this implementation, most of the wiring is localized with only a single power supply required for the BCU (which then distributes power locally to the door actuators) and a CAN and/or LIN connection extending to the rest of the vehicle. The key advantages are a dramatic reduction in the weight, complexity, and cost of the wiring harness, and flexibility in the design of the BCU to suit the specific door for which it is designed. For example, front door BCUs require additional functionality to service door mirrors (Figure 2).

Figure 2: A decentralized system reduces wiring harness weight and complexity. (Image source: ON Semiconductor)

Figure 2: A decentralized system reduces wiring harness weight and complexity. (Image source: ON Semiconductor)

While the decentralized topology is gaining in popularity, there is no suggestion that the centralized approach is going away. The choice of either design method is largely determined by the trade-off between cost and wiring harness complexity.

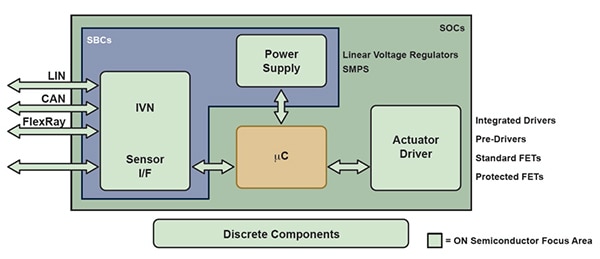

Vendors supply solutions which simplify the design of either decentralized or centralized solutions. For example, ON Semiconductor supplies a wide range of ASICs, ASSPs and discrete components for door electronics; designers are then free to select their favorite microcontroller (Figure 3).

Figure 3: ON Semiconductor provides a range of ASIC, ASSP and discrete solutions for decentralized and centralized BCUs, leaving the designer free to choose their favorite microcontroller. (Image source: ON Semiconductor)

Figure 3: ON Semiconductor provides a range of ASIC, ASSP and discrete solutions for decentralized and centralized BCUs, leaving the designer free to choose their favorite microcontroller. (Image source: ON Semiconductor)

In-vehicle networks

Whether designers choose a decentralized or centralized design for door electronics control, they will need to ensure the BCU is integrated into the IVN. CAN connectivity is facilitated by a CAN controller paired with a CAN transceiver that forms the interface between the controller and the physical bus. Examples of CAN transceivers suitable for automotive applications include ON Semiconductor’s NCV7341D21R2G, a high-speed 1 megabit per second (Mbit/s) CAN device. The chip features a differential receiver with a high common-mode range for good electromagnetic immunity (EMI) in challenging automotive environments. In addition, the chip’s bus pins are protected against the voltage transients that can plague automotive electrical systems (Figure 4).

Figure 4: Typical application schematic for NCV7341D21R2G CAN transceiver with 5 volt CAN controller. The transceiver is a good choice for connecting to the IVN for either decentralized or centralized car door systems. (Image source: ON Semiconductor)

Figure 4: Typical application schematic for NCV7341D21R2G CAN transceiver with 5 volt CAN controller. The transceiver is a good choice for connecting to the IVN for either decentralized or centralized car door systems. (Image source: ON Semiconductor)

A decentralized system will require not only CAN connectivity to the IVN but also LIN connectivity between the front and rear BCUs, as shown in Figure 2. The front door BCU is connected to the CAN, but to save cost and wiring, the rear BCU is daisy-chained to the front BCU by LIN. LIN features a single wire to each node, simplifying wiring and lowering cost. While throughput is limited to a maximum of 20 kilobits per second (kbits/s), this is adequate for control of devices such as door locks, windows and door mirrors.

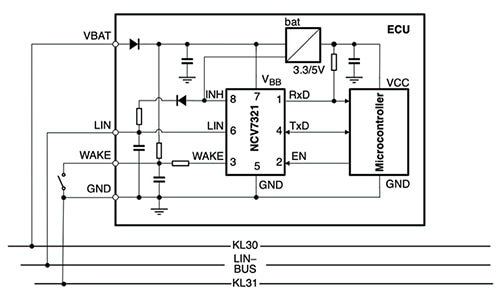

ON Semiconductor’s NCV7321D12R2G LIN transceiver is a good choice for the LIN connectivity of door mounted electronics. The chip incorporates the LIN transmitter, LIN receiver, power-on-reset (POR) circuits, thermal shutdown, and four operating modes (unpowered, standby, normal and sleep). The modes are determined by the supply voltage (VBB, 5 to 27 volts), input signals enable (EN) and WAKE, and activity on the LIN bus. The transceiver is optimized for maximum throughput and features good EMI characteristics due to the low slew rate of the LIN output.

LIN topology uses a single master node controlling a series of up to 16 slave nodes. In a decentralized system, the front and rear BCUs incorporate a master node, while peripheral units like window control panels incorporate slave nodes, per Figure 2. The master node pairs the LIN transceiver with a suitable microcontroller (Figure 5).

Figure 5: Typical application schematic for NCV7321D12R2G LIN transceiver in master node configuration. Each master node can control up to 16 slave nodes. (Image source: ON Semiconductor)

Figure 5: Typical application schematic for NCV7321D12R2G LIN transceiver in master node configuration. Each master node can control up to 16 slave nodes. (Image source: ON Semiconductor)

Door actuator drivers

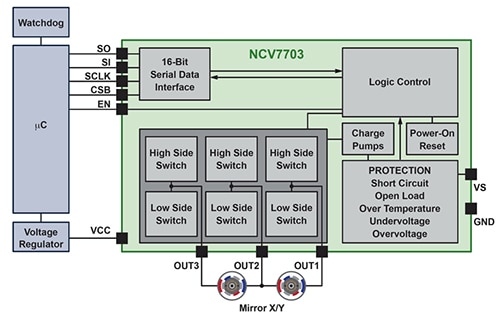

Other key components of BCUs for either decentralized or centralized topologies are the actuator drivers required to power the door locks, mirrors, windows, and other systems. ON Semiconductor offers the NCV7703CD2R2G, a triple half-bridge driver designed specifically for automotive and industrial motion control for these applications. The three half-bridge drivers can be independently controlled via a standard Serial Peripheral Interface (SPI) and supply a typical output of 500 milliamps (mA) with a maximum of 1.1 amps (A). The chip can be powered with a supply voltage from 3.15 to 5.25 volts, and a load voltage from 5.5 to 40 volts.

A key design restriction is the maximum die temperature. A die temperature of 150°C should not be exceeded even if it places a limit on how many of the device’s three drivers can be used at the same time.

Output drive control (and fault reporting) is handled via the SPI port. An EN function provides a low quiescent sleep current mode when the device is not in use, and a pull down resistor is provided on the EN, SI and SCLK inputs to ensure they default to a low state in the event of an interrupted input signal.

How the NCV7703CD2R2G triple half-bridge driver is used in a door mirror positioning system is shown in Figure 6. In this arrangement, the output from the three half-bridge drivers powers the two electric motors used to move the mirror in the X and Y directions.

Figure 6: A block diagram of the ON Semiconductor NCV7703CD2R2G triple half-bridge driver in a mirror position adjustment application shows how the output from the three half-bridge drivers powers the two electric motors used to move the mirror in the X and Y directions. (Image source: ON Semiconductor)

Figure 6: A block diagram of the ON Semiconductor NCV7703CD2R2G triple half-bridge driver in a mirror position adjustment application shows how the output from the three half-bridge drivers powers the two electric motors used to move the mirror in the X and Y directions. (Image source: ON Semiconductor)

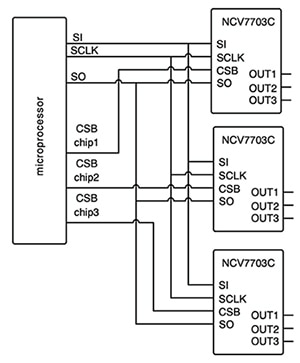

A single microprocessor can be used to control multiple NCV7703CD2R2G triple half-bridge drivers, reducing the door electronics’ BOM. The most efficient way to do this is to operate the drivers in parallel with each device controlled in a multiplexed fashion.

In a serial configuration, the programming information for the last device in the serial string must first pass through all the previous devices. A parallel control topology eliminates that requirement, but at the cost of narrowing processor selection to a device that features chip select (CSB) pins for each driver. The serial data is then only recognized by the device that is activated through its respective CSB pin (Figure 7).

Figure 7: BOM cost for door electronics can be lowered by using a single microprocessor to control multiple triple half-bridge drivers. (Image source: ON Semiconductor)

Figure 7: BOM cost for door electronics can be lowered by using a single microprocessor to control multiple triple half-bridge drivers. (Image source: ON Semiconductor)

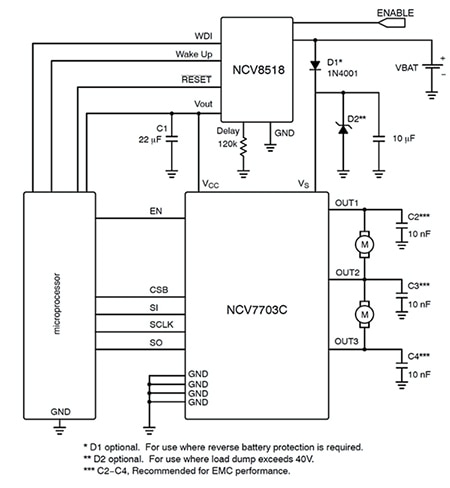

The NCV7703CD2R2G triple half-bridge driver requires 5 volt regulation on its supply input for internal operation. A good option for this requirement is the ON Semiconductor NCV8518BPWR2G linear voltage regulator. The chip has a fixed output of 5 volts and regulates within ±2%. It is suitable for use in all automotive environments and has a low dropout voltage of 425 millivolts (mV) typical, and a low quiescent current of 100 microamps (µA). Safety features include thermal shutdown, short circuit protection, and the ability to handle up to 45 volt transients. The linear voltage regulator can also be used to power the BCU’s microprocessor (Figure 8).

Figure 8: The NCV8518BPWR2G linear voltage regulator is a good choice for supplying a 5 volt output for actuator driver and microprocessor on a BCU. (Image source: ON Semiconductor)

Figure 8: The NCV8518BPWR2G linear voltage regulator is a good choice for supplying a 5 volt output for actuator driver and microprocessor on a BCU. (Image source: ON Semiconductor)

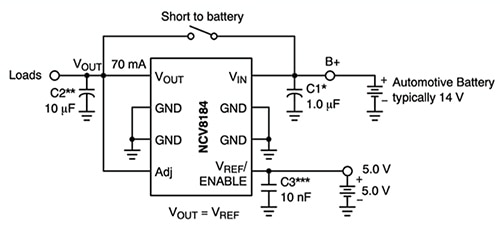

An alternative linear voltage regulator for parts of the door electronics that require a lower cost option is the NCV8184DR2G. The chip provides an adjustable buffered output voltage between -3.0 and 45 volts that closely tracks (±3.0 mV) the reference input. Its operating voltage is from 4.0 to 42 volts.

A useful feature of the NCV8184DR2G is that in a conventional configuration, it can survive a short to the car battery with no damage (Figure 9). The chip can also endure a short to the battery when powered by an isolated supply at a lower voltage.

Figure 9: The NCV8184DR2G is a lower cost option for BCU voltage regulation and can withstand a short to the vehicle battery. (Image source: ON Semiconductor)

Figure 9: The NCV8184DR2G is a lower cost option for BCU voltage regulation and can withstand a short to the vehicle battery. (Image source: ON Semiconductor)

Discrete components

In addition to monolithic devices for IVNs, actuator drivers and voltage regulation, ON Semiconductor offers a range of discrete components for door electronics such as automotive grade Zener diodes. These can be used to protect the sensitive silicon in BCUs from voltage spikes caused by external factors such as lightning and electrostatic discharge (ESD) through transient voltage suppression (TVS). (For more on protection of automotive electronics see DigiKey library article, “Design In TVS Diode Protection to Enhance CAN Bus Reliability.”)

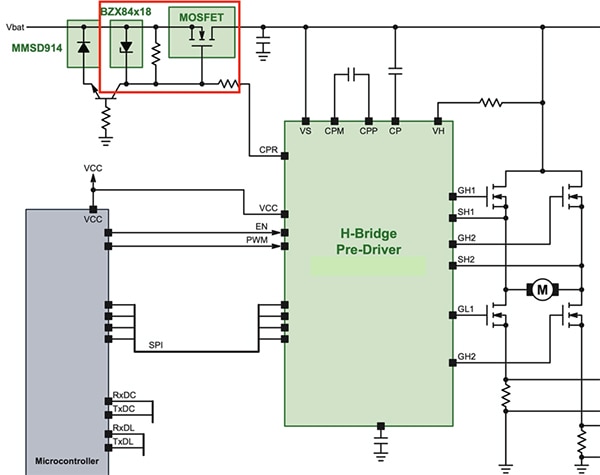

A second application for Zener diodes—combined with a resistor and MOSFET—is to form the basis for an inexpensive and compact linear voltage regulator. A linear voltage regulator can be assembled from discrete components regulating the power supply voltage from the vehicle battery to power actuator pre-drivers and drivers (Figure 10). An automotive battery supplies around 14 volts while the power supply voltage (VS) for the NCV7703CD2R2G triple half-bridge driver can be between 5.5 and 40 volts. This simple and inexpensive Zener diode linear voltage regulator maintains a steady voltage for the door electronics as the voltage output from the car battery varies.

Figure 10: A portion of a door electronics BCU shows a linear voltage regulator assembled from discrete components (highlighted). The device regulates the vehicle battery voltage (Vbat) to the power supply voltage (VS) required for actuator bridges. (Image source: ON Semiconductor)

Figure 10: A portion of a door electronics BCU shows a linear voltage regulator assembled from discrete components (highlighted). The device regulates the vehicle battery voltage (Vbat) to the power supply voltage (VS) required for actuator bridges. (Image source: ON Semiconductor)

A suitable Zener Diode for this application is ON Semiconductor’s SZBZX84C5V1LT3G. This is an automotive (AEC-Q101) grade Zener diode supplied in the compact SOT-23 package. These devices provide voltage regulation with minimum space requirements. The Zener diode has a maximum power dissipation of 250 milliwatts (mW) and a Zener breakdown voltage capability ranging from 2.4 to 75 volts, depending upon the component selected.

The full regulator requires a resistor to limit the current flowing through the Zener diode. The resistor should be chosen to allow enough current to flow to the load and to the Zener in order to allow for regulation, but not much more. The Zener regulator has a high source impedance because all load current must travel through the current limiting resistor, restricting the amount of current that the regulator can provide to the load. This limitation is overcome by buffering the output of the Zener diode with a source follower such as the MOSFET shown in Figure 10. (For more information, see Maker.io article “Zener Diode Regulator with Transistor Current Buffer.”)

Conclusion

Door electronics have become increasingly complex as automotive manufacturers add more functionality to their vehicles. This trend has made it more difficult for engineers to design systems that meet tough cost, weight, space, and reliability constraints.

As shown, ASICs, ASSPs and discrete components designed to meet automotive standards that complement each other ease the design challenge and allow a modular approach to door electronics design. Such an approach makes it simpler to meet specification and BOM constraints while maintaining good performance and reliability.

Related articles

Disclaimer: The opinions, beliefs, and viewpoints expressed by the various authors and/or forum participants on this website do not necessarily reflect the opinions, beliefs, and viewpoints of DigiKey or official policies of DigiKey.