Supporting Mass Customization, High Quality, and Sustainable Operations in Industry 4.0 Factories

Contributed By DigiKey's North American Editors

2023-07-27

Supporting mass customization with high-quality and sustainable production processes can be challenging for designers of Industry 4.0 automated manufacturing systems. Multiple sensing and control devices need to be deployed and connected across various wired and wireless networks, and their state and energy consumption need to be monitored in real-time, all while meeting established sustainability standards.

To accommodate the variety of functions, networks, monitoring, and standards requirements, while also ensuring scalability and flexibility, automation system designers for Industry 4.0 don’t have to piece it all together themselves. They can instead, incorporate compact integrated controllers to implement flexible production systems with high levels of quality and sustainability. These controllers have numerous embedded control and energy management functions, digital and analog inputs and outputs (IOs), and the secure communications capabilities necessary to implement a scalable, flexible, and highly sustainable Industry 4.0 factory.

This article provides a brief overview of typical Industry 4.0 factory automation elements and requirements. It then introduces a family of compact and expandable controllers from Siemens as examples of programmable logic controllers (PLCs), which contain integrated communications interfaces and technology functions. It closes with a review of the International Standards Organization (ISO) 50001 and related standards for operational energy management, including an example of an energy management implementation for sustainability.

Key elements of an Industry 4.0 factory

A typical Industry 4.0 factory application comprises devices like temperature controls, pump and fan controls, conveyor systems, and packaging machines that require flexible integration and precision to ensure high-quality production. In addition, the energy consumption of these devices needs to be continuously monitored and analyzed to support efficient and sustainable operations. Additionally, it all needs to be supported with multiple layers of wired and wireless connectivity, ranging from distributed sensors and controllers to motor drives, energy meters, and machine technicians and operators in real time.

To address these diverse needs while speeding process deployment and reconfiguration, maximizing uptime, and ensuring efficient operation, automation system designers need dedicated process controllers with several key features. Such features include secure communication interfaces, digital and analog IOs, as well as integrated control functions like high-speed counters, pulse width modulation (PWM), pulse sequence outputs, speed control, positioning, condition monitoring, and energy management. In addition, communications interfaces need to be available that support protocols like serial communication, PROFIBUS, IO-Link, actuator sensor interface (AS-Interface), MODBUS real-time unit (RTU), universal serial interface (USI), TCP/IP, and mobile wireless standards.

Industry 4.0 connectivity

To cater to Industry 4.0 connectivity requirements, the SIMATIC S7-1200 family of PLCs from Siemens supports the connection of sensors, actuators, and motors to human-machine interfaces (HMIs) and to the cloud. It uses the OPC Unified Architecture (OPC UA), a machine-to-machine (M2M) communication protocol for industrial automation. OPC UA has a platform independent, service oriented architecture that simplifies connectivity. It supports the integration of all classes of devices, automation systems, and software applications in an inherently secure environment. It includes field extensions specified by the Field Level Communication (FLC) initiative, based on the OPC UA Framework and specified in International Electrotechnical Commission (IEC) 62541.

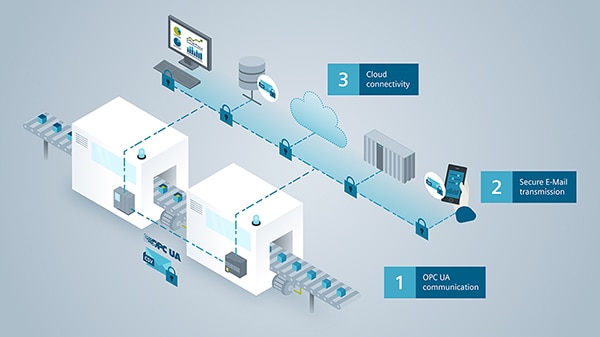

FLC provides equipment suppliers with an independent platform for secure and reliable communications that emphasizes authentication, signing, and data encryption. OPC UA is more than an M2M communications protocol; it’s designed to support connections between the factory network and business networks. OPC UA Data Access on Siemens’ SIMATIC S7-1200 PLCs provides for standardized horizontal and vertical communication, as well as compliance with industry-specific requirements such as The Organization for Machine Automation and Control Packaging Machine Language (OMAC PackML), an automation standard that makes it easier to transfer consistent machine data, as well as the Weihenstephan Standards (WS), which define a communication interface for the standardized transmission of machine data to higher level IT systems. Key features of OPC UA implementations on S7-1200 PLCs include (Figure 1):

- The ability to efficiently add new processes between PLCs and any higher level, business oriented software layers.

- A simplified implementation of industry-specific companion specifications with Siemens OPC UA Modeling Editor.

- Cloud connectivity through a wireless connection to an Ethernet network.

- DNS name resolution for simplified addressing with open user communication (OUC), including encryption.

- A means to send emails securely, with optional attachments.

Figure 1: OPC UA is a foundational element of Industry 4.0 factory connectivity. (Image source: Siemens)

Figure 1: OPC UA is a foundational element of Industry 4.0 factory connectivity. (Image source: Siemens)

Scalable controllers

In addition to integrated support for OPC UA communication, S7-1200 controllers like the 6ES72141AG400XB0 (Figure 2) and the 6ES72151BG400XB0 are highly flexible and scalable. The former operates from a 24-volt direct current (VDC) power supply and has 24 VDC inputs and outputs, while the latter operates from a 120 or 230 volt alternating current (VAC) power supply, with 24 VDC inputs and relay outputs.

All S7-1200 controllers have integrated IOs, are modularly expandable, and have several communications options. The Siemens Totally Integrated Automation (TIA) portal provides a simple software environment for developing control programs, and the SIMATIC automation tool can be used in the field for operating and maintaining SIMATIC S7-1200 controllers. Additional features include:

- A PROFINET interface to support scalability and flexibility.

- Security features that include comprehensive access, copy, and manipulation protection.

- Diagnostics, with messages displayed in simple, plain text in the Siemens TIA Portal, through a web server, on the SIMATIC HMI, and in the SIMATIC Automation Tool with no additional programming.

- Safety features in certain models that can execute both standard and safety-related programs for applications up to Safety Integrity Level 3 (SIL3) defined in IEC 61508, and IEC 62061 and Performance Level e (PLe) defined in ISO 13849.

Figure 2: Siemens S7-1200 controllers have integrated OPC UA communications support. (Image source: Siemens)

Figure 2: Siemens S7-1200 controllers have integrated OPC UA communications support. (Image source: Siemens)

Integrated technology functions like high-speed counters, PWM, pulse sequence outputs, speed control, and positioning make these controllers suitable for temperature control, pump and fan control, conveyor technology, and packaging machines. They are optimized for loop control, weighing, energy management, high-speed counting, radio frequency identification (RFID), and condition monitoring.

Flexible communications options

Comprehensive networking options are a hallmark of S7-1200 PLCs. Supported communications protocols include:

PROFINET: An open Industrial Ethernet (IE) standard. The integrated PROFINET interface uses TCP/IP standards and can be used for programming or to communicate with HMI devices and additional controllers.

PROFIBUS: This is a fieldbus standard. With PROFIBUS, S7-1200 controllers can establish uniform communication from the field level to the control level.

AS-Interface: This is a fieldbus standard for actuators and sensors. Up to 62 AS-Interface standard slaves, such as motor starters, position switches, and modules can be connected.

In addition to the integrated communications capabilities, modules are available that support additional protocols such as:

- CANopen

- Modbus RTU

- Modbus TCP

- IO-Link

- General Packet Radio Service (GPRS)/Long Term Evolution (LTE)

- RS-485, RS-422, and RS-232

- USS

Achieving mass customization and high quality

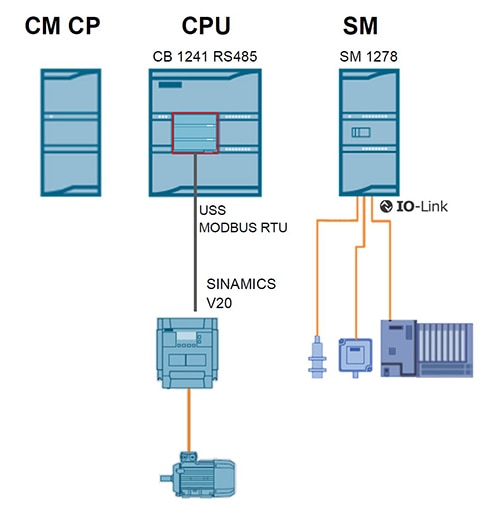

Their wide range of functionality and communications capabilities allow the S7-1200 PLCs to accommodate the drive toward mass customization and high quality that’s occurring as part of Industry 4.0. While there are numerous ways to achieve those goals, the following example shows the use of communication expansion modules for wireless cellular connectivity, RS-485/USS/Modbus RTU serial connectivity for motor control, and IO-Link for simpler connectivity to sensors and actuators, relative to field buses (Figure 3).

Figure 3: Expandable communications for S7-1200 PLCs are supported by a combination of external (left and right) and internal (red box top center) expansion modules. (Image source: Siemens)

Figure 3: Expandable communications for S7-1200 PLCs are supported by a combination of external (left and right) and internal (red box top center) expansion modules. (Image source: Siemens)

In Figure 3, the “CM CP” is a GPRS wireless communications module like the 6GK72427KX310XE0 that can be used for cloud connectivity. An RS-485 communication board like the 6ES72411CH301XB0 resides inside an S7-1200 PLC (“CPU”) and is used to communicate with a motor drive (the SINAMICs V20) through the USS/Modbus RTU interface. The “SM” on the right comprises an IO-Link master communications module like the 6ES72784BD320XB0. The IO-Link master is connected to two sensors on the left and center, as well as to an IO-Link hub on the right. The hub can connect to additional IO-Link devices.

Sustainable energy management

Improved energy efficiency and sustainability rely on smart energy management, which in turn relies on more granular and real-time energy consumption data. It increasingly begins with the consideration of ISO 50001 standards for operational energy management. This is a foundational standard that provides a framework of requirements, including the development of policies, targets, and objectives for more efficient energy use, and the use of data to measure the results. ISO 50001 is supported by additional standards, including:

- ISO 50003 ensures the effectiveness of energy management systems (EnMS). It encompasses auditing, personnel competence requirements, and the duration of audits and multi-site sampling.

- ISO 50004 helps organizations take a systematic approach toward achieving continual improvement in energy management and energy performance.

- ISO 50006 expands on how to meet ISO 50001 requirements, including the development and maintenance of energy performance indicators (EnPIs) and energy baselines (EnBs) for ongoing performance monitoring.

The EnPIs and EnBs in ISO 50006 enable the effective measurement and management of energy performance, which can help to optimize energy efficiency. In addition to improvements in sustainability, better energy management leads to significant cost savings. The standard defines the starting point (EnBs) and meaningful performance metrics (EnPIs), and it identifies four types of indicators; “absolute” and “relative energy performance indicators”, along with “statistical” and “technical” models.

Siemens’ S7-1200 controllers can simplify the implementation of these ISO standards and support highly effective energy management systems. Automation system designers can add an energy meter module to enable measurement, evaluation, and display of energy consumption data in real time. Figure 4 illustrates a typical application:

- The motor represents a typical load being monitored for energy consumption.

- The current transformer transforms the energy consumption into a measurable quantity for the energy meter module. The meter also measures numerous other parameters like voltage and power factor.

- Software in the S7-1200 controller evaluates the measurements and saves statistics on the energy consumption in a data log. It’s connected to the PG/PC and HMI through a SCALANCE industrial router using PROFINET IE buses.

- The HMI displays the measured values and enables operators to evaluate parameters such as power consumption peaks over time.

- The controller can also send the data log onto the PG/PC in the form of standard web pages.

Figure 4: Shown is a typical energy monitoring application that can be easily supported with an S7-1200 PLC. (Image source: Siemens)

Figure 4: Shown is a typical energy monitoring application that can be easily supported with an S7-1200 PLC. (Image source: Siemens)

Energy meter module

In an application such as that shown in Figure 4, an SM 1238 energy meter module can be used for data acquisition (Figure 5). It can be used in single and three-phase supply systems up to 480 VAC. These modules can provide S7-1200 controllers with the data needed to support compliance with ISO 50001, 50003, 50004, and 50006 requirements. They can record over 200 electrical measurements and energy values, including:

- Currents

- Voltages

- Phase angles

- Frequencies

- Power factors

- Power consumption

- Minimum and maximum values

- Operating hours

- Energy/electrical work

Figure 5: The SM 1238 is an energy monitoring module for single and three-phase power systems. (Image source: Siemens)

Figure 5: The SM 1238 is an energy monitoring module for single and three-phase power systems. (Image source: Siemens)

Conclusion

To simplify and accelerate the deployment of sustainable Industry 4.0 factory networks, automation system designers can use the S7-1200 family of PLCs and expansion modules. These solutions support a wide range of secure communications options, have integrated control functions and digital and analog IOs, and are expandable to support a wide array of applications, including energy management.

Recommended reading

Disclaimer: The opinions, beliefs, and viewpoints expressed by the various authors and/or forum participants on this website do not necessarily reflect the opinions, beliefs, and viewpoints of DigiKey or official policies of DigiKey.