How to Use Traceability 4.0 Solutions for Improved Product Safety, Compliance, and Tracking

Contributed By DigiKey's North American Editors

2023-02-07

Real-time asset tracking and traceability in warehouses and factories is an important aspect of Industry 4.0 and supply chain management for automotive parts and sub-assemblies, consumer white goods, aerospace, transportation, and electronic system production. Traceability is especially important: It includes location tracking and documenting the history and usage of raw materials, components, subassemblies, and finished goods. In addition to supporting production efficiency and product quality, traceability 4.0 is an essential aspect of product safety, including safeguarding against counterfeit components, supporting accurate recalls, and ensuring regulatory compliance.

Traceability 4.0 solutions rely on marking every individual component, often using 1D or 2D barcodes on labels or directly marked on the items, and actively tracking the movement of items throughout the production process. That can be quite a challenge. For example, a typical automobile has over 20,000 components that must be tracked. Traceability 4.0 implementation can be complex. It's not enough to simply mark every component. Using a single imaging platform for bar code reading and visual inspection of the items is desirable. Additionally, the imagers need to operate in harsh industrial environments and under variable lighting conditions.

To support the traceability needs of Industry 4.0, designers can turn to industrial smart imagers that can read 1D and 2D barcodes for visual inspection and are available with autofocus to improve imaging performance. These smart imagers include advanced decoding algorithms that can read even damaged barcodes. They have double front window construction to minimize issues with condensation, as well as IP65/67 protection to ensure performance in harsh environments.

This article reviews the development of traceability 4.0 and how it supports product safety, product tracking, and regulatory compliance, reviews the basic barcode types and reconstruction software to read damaged barcodes, looks at system integration issues and the tradeoffs between mechanical and liquid lens autofocusing systems and closes by presenting smart industrial imagers from Omron along with a software development tool for setting up barcode reading and machine vision applications.

Where does traceability 4.0 fit?

Traceability 4.0 is an integral part of industry 4.0. But not every manufacturing operation is an industry 4.0 operation. Other use cases, like retail and warehousing, don't require traceability 4.0. So, how did traceability 4.0 arise (Figure 1)?

- Traceability 1.0 usually relies on barcodes to automatically identify products to improve accuracy and efficiency.

- Traceability 2.0 moved into supply chain management using date and lot codes. It was designed to support higher levels of quality, and consumer confidence and support targeted product recalls. It's still used in the retail industry. In addition, the U.S. Food and Drug Administration (FDA) uses it for unique device identifiers (UDIs) for medical devices. This is when the International Standardization Organization (ISO) began developing barcode quality specifications.

- Traceability 3.0 marked the beginning of tracking individual devices instead of date and lot codes. Direct part marking (DPM) technologies for plastic and metal parts were developed for use in harsh industrial environments. The basis for anti-counterfeiting programs was developed to ensure product and component authenticity.

- Traceability 4.0 is the complete implementation, including comprehensive part history and individual part geometric dimensioning and tolerancing (GD&T). GD&T is vital in precision manufacturing like aerospace and automotive manufacturing and enables the installation of parts based on their exact GD&T values, ensuring high precision assemblies and supporting high-quality systems.

Figure 1: Traceability 4.0 is an integral part of industry 4.0 but does not entirely replace previous generations of traceability. (Image source: Omron)

Figure 1: Traceability 4.0 is an integral part of industry 4.0 but does not entirely replace previous generations of traceability. (Image source: Omron)

Bar code types and standards

Barcode types have evolved and expanded as traceability becomes more sophisticated. Today, there are multiple common barcode types, including linear, 2D (like Data Matrix, QR Code, and Aztec Code), and stacked linear (like PDF 417, Micro PDF, and Composite Codes) (Figure 2). They can be printed on labels attached or directly marked on the part. There's a wide range of standards. Examples include:

- AIAG B4 – Automotive Industry Action Group Parts Identification and Tracking

- AS9132 – Society of Aerospace Engineers, Data Matrix Quality Requirements for Part Marking

- EIA 706 – Electronics Industry Association, Component Marking

- ISO/IEC 16022 – International Symbology Specification

- ISO/IEC 15418 – Symbol Data Format Semantics

- ISO/IEC 15434 – Symbol Data Format Syntax

- ISO/IEC 15415 – 2D Print Quality Standard

- ISO/IEC 15416:2016 – 1D Print Quality Standard

- ISO/IEC TR 29158:2011 – Direct Part Mark (DPM) Quality Guideline

- SPEC 2000 – Air Transport Association, Electronics Commerce, Including Permanent Part ID

- IUID – U.S. Department of Defense, Permanent & Unique Item Identification

- UDI – FDA medical device identification

Figure 2: Traceability 4.0 can support using various barcode styles. (Image source: Omron)

Figure 2: Traceability 4.0 can support using various barcode styles. (Image source: Omron)

What about damaged barcodes?

Barcode marking is subject to variations; it's not perfect. Even well-printed barcodes can become damaged or skewed as a part moves through the manufacturing process. Lack of contrast between the part surface and the barcode and highly variable lighting in industrial environments contribute to the challenges that must be addressed when developing a traceability 4.0 infrastructure.

To address the challenges of accurately reading a wide range of barcodes under widely varying conditions, Omron offers its X-Mode algorithms that can read virtually any code on any surface, including shiny, textured, or curved. Using X-Mode can minimize so-called "no reads," minimizing delays and downtime.

X-Mode uses advanced digital image processing and pixel analysis to make distorted, damaged, poorly printed, or skewed symbols readable. For DPM codes like inkjet printed codes on cardboard and other packaging or dot peen marks on reflective metal surfaces, X-Mode enhances contrast and sharpness of the image to reliably read and interpret codes in even dynamic environments (Figure 3). X-Mode also supports omnidirectional decoding, increasing the range of usable mount angles and simplifying the integration of barcode readers.

Figure 3: Advanced digital imaging and pixel processing enable X-Mode software to read codes under challenging conditions. (Image source: Omron)

Figure 3: Advanced digital imaging and pixel processing enable X-Mode software to read codes under challenging conditions. (Image source: Omron)

System integration

Real traceability 4.0 systems require multiple cameras integrated into an easy-to-use and easy-to-manage system. With these smart industrial imagers, process engineers can combine up to eight readers using an Ethernet switch to support 360-degree code reading and product inspection when a combined output of multiple codes is needed or when the code location is unpredictable.

High-mix manufacturing that's typical of industry 4.0 operations can be supported by automatically selecting from multiple settings to maximize read rates and line speed using the best options based on barcode size, type, lighting and contrast, and location. The system uses ISO standard grading methods for inline monitoring of barcode quality and can trigger an alert if the quality falls below a user-set threshold.

These smart industrial imagers have an integrated web-based barcode reader interface. Each imager is securely accessible on any web-enabled device using its IP address. The open protocol structure simplifies device integration and eliminates problems with device incompatibility. Web integration includes three user access levels. At the highest level of security and access, users can edit settings that can be saved to the reader's internal memory or on external devices and transferred to other devices to speed the integration of new equipment and changing environment needs.

To reduce overall equipment costs, the inspection status of multiple readers can be monitored with a single device. While standard imagers require one display per device, these smart industrial imagers require only one display for multiple devices. That simplifies installation and monitoring of multiple imagers. In addition, web monitoring software is integrated into each smart industrial imager, enabling remote monitoring of multiple imagers using a tablet or personal computer.

Autofocusing choices

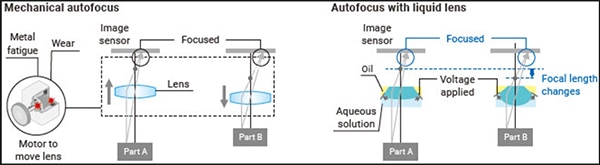

Autofocusing capability can significantly impact the performance of barcode reading systems in challenging environments. These smart industrial imagers offer a choice of mechanical and liquid lens autofocusing. Mechanical autofocus is implemented with a small motor. Its mechanical nature means it’s subject to wear and metal fatigue and can require replacement on an annual basis. Liquid lens autofocusing changes the lens's focal length by applying a voltage to change the shape of an internal structure consisting of oil and water (Figure 4). Since there's no mechanical wear, liquid autofocus mechanisms can have operating lifetimes of multiple years. With liquid lens technology, the imager can automatically adjust the focus from 50 millimeters (mm) to 1,200 mm and read even high-density data matrix symbols on complex printed circuit boards. Imagers with either type of autofocus can read any code in seconds after being connected, with no setup required.

Figure 4: Mechanical autofocus (left) requires more maintenance resulting in more downtime than liquid lens autofocusing (right). (Image source: Omron)

Figure 4: Mechanical autofocus (left) requires more maintenance resulting in more downtime than liquid lens autofocusing (right). (Image source: Omron)

Smart industrial imagers

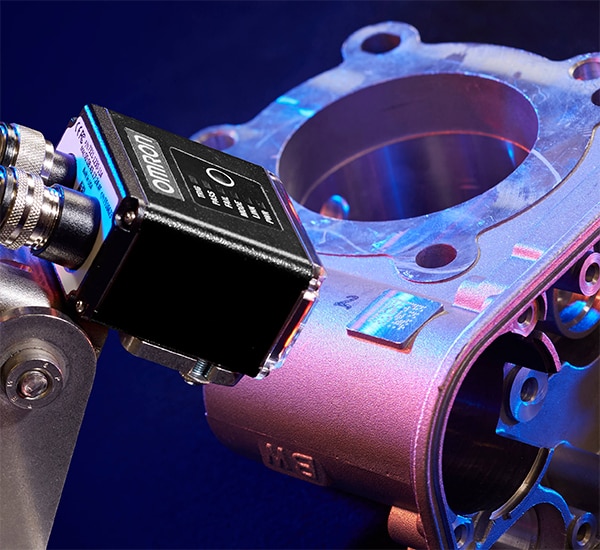

Omron MicroHAWK code readers provide fast and reliable operation and have a rugged, ultra-compact housing with double front window construction to help avoid moisture condensing inside the window. Depending on the model, they are available with IP65/67 protection to assure performance in challenging environments. Image resolutions are available from 0.3 to 5 megapixels. These imagers are available with optics, lighting, and filtering options to optimize the device for the specific operating environment and imaging needs. MicroHAWK features include:

- Ethernet/IP, Ethernet TCP/IP, and PROFINET connectivity

- 5 to 30 VDC power input with option for power over Ethernet (PoE)

- 800 MHz processor speed to support fast image processing

- Non-linear calibration (NLC) function improves measurement and locator performance by a factor of 20 by canceling out lens distortion. It outputs measurements in mm and pixels.

The same device can support up to 60 frames per second for barcode reading and visual inspection. Examples of MicroHAWK code readers include:

- V430-F000W12M-SRP, 1.2 MP imager with wide field of view 5.2 mm focal length lens, plus standard autofocus, standard red outer light, and plus-mode imaging (Figure 5)

- V430-F000L12M-SRX, 1.2 MP imager with narrow 16 mm lens and autofocus to 1,160 mm, standard red outer light, and X-Mode imaging

Figure 5: This 1.2 MP imager has a wide 5.2 mm focal length lens and plus-mode imaging software. (Image source: DigiKey)

Figure 5: This 1.2 MP imager has a wide 5.2 mm focal length lens and plus-mode imaging software. (Image source: DigiKey)

Efficient setup

Omron's AutoVISION software can speed the setup and installation of MicroHAWK imagers. With AutoVISION, users can connect to and configure a device, as well as program and monitor a job. AutoVISION jobs are scalable across multiple MicroHAWK imagers, software packages, industrial systems, and tablets and PCs. It can integrate up to 8 imagers into a single system. With AutoVISION, these smart imagers can be used for machine vision inspection functions like part presence, part location, part counting, color detection, and making dimensional measurements. Implementing AutoVISION is a three-step process:

- Capture an image with one click

- Specify inspection area and assign outputs with drag and drop tool

- Start the inspection process with the run button

AutoVISION development software is suitable for a range of applications:

- Inspection and general machine vision

- Packaging lines

- Assembly processes

- Defect detection

Summary

Traceability 4.0 supports Industry 4.0 manufacturing processes and supply chains but does not completely replace earlier versions of traceability in other applications. High-performance imagers are a critical element in the deployment of traceability 4.0. Smart industrial imagers are available with autofocusing capabilities and the ability to operate reliably under challenging environmental and lighting conditions. NLC software improves measurement accuracies by up to 20X, and available auto-configuration software speeds the deployment of high-performance traceability systems.

Disclaimer: The opinions, beliefs, and viewpoints expressed by the various authors and/or forum participants on this website do not necessarily reflect the opinions, beliefs, and viewpoints of DigiKey or official policies of DigiKey.