Selecting and Optimizing Batteries in Medical Devices

Contributed By DigiKey's North American Editors

2024-06-20

Selecting the best battery for a portable medical device is as important as choosing the suitable processor, wireless chip, and flash memory. A poor choice of energy source could seriously compromise the performance of an otherwise well-designed product.

Because the voltage of any type of battery varies with parameters such as charge, load, and temperature, regulation is needed to ensure a reliable constant voltage to the load.

This article provides a brief overview of battery chemistries suitable for medical devices. It then introduces voltage regulation options from Analog Devices and uses a practical application to show how they are applied.

Understanding battery characteristics

The following parameters influence battery selection for a medical product:

- Requirement of a primary or secondary (rechargeable) battery

- Battery size, voltage, internal resistance, capacity, and specific energy

- Battery electrochemistry

- Applicable regulations

Primary batteries have a lower self-discharge current than secondary cells. This makes them more suitable for systems with extended time between uses. The disadvantage is the need to replace and dispose of the cell once discharged.

Secondary batteries are better suited to applications with relatively high current draw. They are generally more expensive than primary cells, and system complexity is increased because of the need to incorporate charging circuitry.

System dimensions help determine the limitations on the physical size of the battery, while target battery life and system average current draw help determine the required capacity. Greater specific energy (kilojoules per kilogram (kJ/kg)) allows a lighter battery for a given energy storage.

A battery’s internal resistance dissipates power. Electrochemistry, case construction materials, and battery dimensions influence this resistance. Also, compact batteries tend to feature higher internal resistance than larger ones. Lithium batteries generally feature lower internal resistance than alkaline types, which makes them suitable for high current draw applications due to the resultant power dissipation. During operation, the internal resistance of a battery will vary depending on the rate and depth of discharge, the temperature, and the battery’s age, among other factors.

The nominal output voltage of a battery is determined by its electrochemistry. For example, a primary nickel-zinc (NiZn) alkaline battery has a nominal voltage of 1.5 volts and a specific energy of 720 kJ/kg (or 200 watt hours per kilogram (Wh/kg)). A primary lithium manganese oxide (LMO) battery has a nominal voltage of 3.0 volts and a specific energy of 1008 kJ/kg (280 Wh/kg).

Zinc-air and silver oxide (Ag2O) are other common electrochemistries. Zinc-air batteries comprise a zinc anode, an electrolytic paste separator, and an ambient air cathode. This type is commonly supplied in a coin cell form factor. Because of its non-metallic cathode, a zinc-air battery is lightweight and comparatively inexpensive. It features a relatively flat discharge curve and a nominal output voltage of 1.4 volts.

Ag2O batteries combine a silver cathode and a zinc anode. They have a nominal output voltage similar to alkaline batteries of 1.55 volts but tend to be supplied with a higher capacity and flatter discharge curve. These batteries are generally safer and feature longer life than lithium batteries with a similar discharge curve.

Table 1 summarizes the various types of primary batteries.

|

Table 1: Shown are the minimum, nominal, and maximum voltages and specific energy for various primary battery electrochemistries. (Image source: Analog Devices)

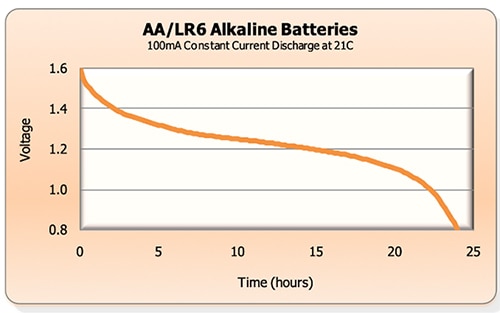

Battery voltage decreases with discharge. Figure 1 shows the output voltage of an AA alkaline battery with a 100 milliampere (mA) constant current load. Regulation is required to ensure that the battery or batteries can supply one or more consistently stable voltages for the system’s components.

Figure 1: Battery voltage decreases as energy is drained. This example shows the output voltage of an AA alkaline battery under a 100 mA constant current load. (Image source: Energizer)

Figure 1: Battery voltage decreases as energy is drained. This example shows the output voltage of an AA alkaline battery under a 100 mA constant current load. (Image source: Energizer)

Batteries for medical systems are subject to standards such as the ANSI/AAMI ES 60601-1. Designers can ensure their shortlisted batteries meet regulatory requirements by working with a respected supplier.

DC/DC conversion options for medical battery-powered systems

Voltage regulation matches the output of the selected battery to various system input voltage requirements. For example, a 3 volt battery might be expected to supply 2 volts to one circuit and 1.1 volts to another. Regulation can also be used to maintain a reliable constant voltage as the battery voltage decreases during discharge.

There are two main categories of commercial DC/DC converters for voltage regulation: the linear low-drop-out (LDO) regulator and the switching regulator. LDOs are simpler but tend to be less efficient and can only step down (buck) the battery voltage. However, an LDO becomes more efficient as the input and output voltage difference decreases (efficiency is proportional to VOUT/VIN). Compact size, lower price, and the lack of voltage ripple noise inherent to switching regulators are other advantages of LDOs.

Switching regulators generally offer higher efficiency; some types can step up (boost) and buck the battery voltage. The downsides of switching regulators are design complexity, a potential for electromagnetic interference (EMI), cost, and a greater printed circuit board (pc board) footprint.

(See “Selecting the Correct Regulator for Your Application” and “Understanding the Advantages and Disadvantages of Linear Regulators”.)

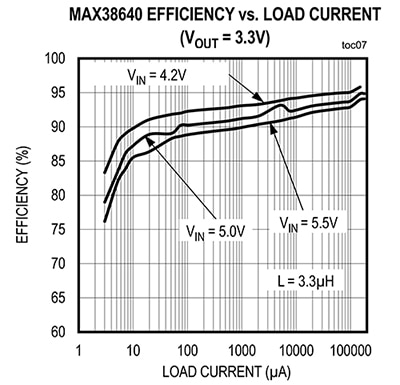

One example of a highly efficient switching buck regulator for medical applications is Analog Devices’ MAX38640AENT+. This device operates from a 1.8 to 5.5 volt input and provides an output between 0.7 and 3.3 volts. The regulator supports load currents of 175, 350, or 700 mA with peak efficiencies of 96%. It also offers 88% efficiency at load currents down to 10 microamperes (µA) (Figure 2). The chip is supplied in a compact 1.42 x 0.89 millimeter (mm), 6-pin wafer level package (WLP), and 2 x 2 mm, 6-pin µDFN package.

Figure 2: The MAX38640 demonstrates good efficiency over a wide load-current range, helping to extend battery life in medical systems. (Image source: Analog Devices)

Figure 2: The MAX38640 demonstrates good efficiency over a wide load-current range, helping to extend battery life in medical systems. (Image source: Analog Devices)

Battery medical application example

An electrocardiogram (ECG) chest patch with a desired run time of five days is a good application example. The patch is disposable, with a non-replaceable battery. It features Bluetooth Low Energy (LE) connectivity to wirelessly transmit the ECG data.

The patch is based on a MAX30001 ECG analog front-end (AFE) and a MAX32655 microcontroller unit (MCU). It also features a MAX30208 temperature sensor and an ADXL367B accelerometer.

Because the application is a disposable patch, the battery must be inexpensive, fully sealed, small, and lightweight. These requirements make the coin cell form factor a good choice.

The end-system’s Bluetooth LE communication and the different operating modes of the MAX32655 MCU demand high currents, making LMO and Ag2O suitable chemistries. LMO has a nominal output voltage of 3.0 volts and a specific energy double that of Ag2O. LMO can be sourced in a convenient CR2032 coin cell form factor with a capacity up to 235 milliampere hours (mAh). Ag2O has a nominal output voltage of 1.55 volts, and the largest coin cell form factor available is the SR44W battery with a capacity of 200 mAh.

The load profile for the ECG chest patch is estimated at around 45 mAh per day: 45 x 5 days = 225 mAh. This is just within the capacity of the 235 mAh LMO battery but beyond that of the 200 mAh Ag2O cell. The LMO battery is, therefore, the best choice for this medical application.

Designing the voltage regulation circuit

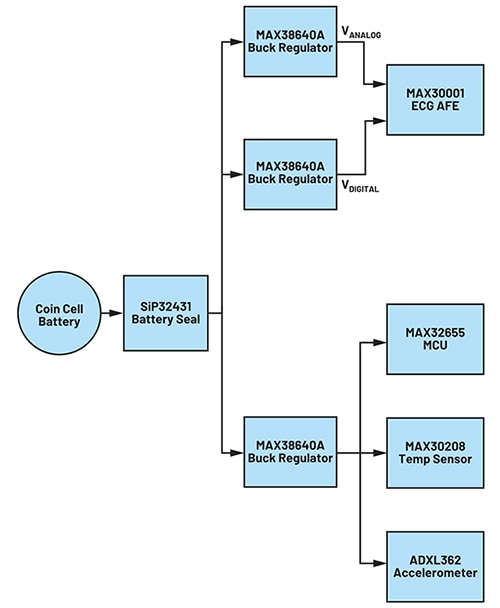

For voltage regulation, the designer can use the nominal 3 volt output from the LMO battery as the input for three MAX38640 buck switching regulators.

Two of these regulators can supply the analog and digital inputs of the MAX30001. They both require a supply of between 1.1 and 2 volts and demand a current well within the regulator's capacity.

Another MAX38640 regulator supplies the MCU, temperature sensor, and accelerometer. The MCU requires a minimum voltage input of 2 volts, the temperature sensor has a minimum requirement of 1.7 volts, and the accelerometer has a minimum requirement of 1.1 volts. The current draw of all three devices is well within the regulator's capacity. Figure 3 shows a schematic of the power supply design that extends battery life to five days.

Figure 3: In the power supply design for an ECG patch with an MCU, a temperature sensor, and an accelerometer, three efficient buck switching regulators extend battery life to five days. (Image source: Analog Devices)

Figure 3: In the power supply design for an ECG patch with an MCU, a temperature sensor, and an accelerometer, three efficient buck switching regulators extend battery life to five days. (Image source: Analog Devices)

Conclusion

Several factors influence the choice of battery for medical devices. To maximize battery life and ensure sensitive ICs receive a stable and noise-free voltage supply, the battery output must be regulated by either LDOs or switching converters. Many commercial modules are available for each category, and the selection is primarily a trade-off between efficiency, cost, and design complexity.

Disclaimer: The opinions, beliefs, and viewpoints expressed by the various authors and/or forum participants on this website do not necessarily reflect the opinions, beliefs, and viewpoints of DigiKey or official policies of DigiKey.