Rapidly Deploy Sensors for IIoT-Based Predictive Maintenance Using MEMS Accelerometers

Contributed By DigiKey's North American Editors

2020-05-28

Condition monitoring of machinery using vibration sensors is a key element of the Industrial Internet of Things’ (IIoT) (or Industry 4.0) goal of predictive maintenance. It allows manufacturing facilities to identify and resolve machinery issues before they trigger catastrophic breakdowns that can halt production while emergency repairs are made. For designers, the traditional approach of using piezoelectric (PE) vibration sensors has bill of materials (BOM) costs as well as wiring expenses and implementation complexities that can limit their deployment.

To lower cost and simplify deployment, designers can instead look at capacitive microelectromechanical systems (MEMS) sensors. Recent improvements in the performance of these sensors have brought them to levels comparable to PE sensors, while retaining the lower cost, greater integration, and industrial tolerance advantages of their CMOS foundations. These improvements include integrated analog-to-digital converters (ADCs), filters, and even embedded building blocks for machine learning to ensure that these devices have cost-effective attributes that justify their widespread installation.

This article discusses the advantages of MEMS capacitive accelerometers in vibration monitoring applications. It then introduces example devices from Analog Devices and STMicroelectronics and shows how they can be deployed quickly as a widespread sensor network for more thorough, cost-effective predictive maintenance sensing of industrial machinery.

Why use vibration for predictive maintenance

Vibration is an indicator long used in condition monitoring, diagnostics, and predictive maintenance of industrial machines. For example, the right sensor, with appropriate processing, can be used to detect issues such as load imbalance, misalignment, ball-bearing failure, and various amplitudes and frequencies of vibration that might indicate another type of failure mode is developing (Figure 1).

Figure 1: The right sensor and appropriate processing can detect issues such as load or motor imbalance and ball-bearing failures, as well as vibrations that might predict another type of developing failure mode. (Image source: Analog Devices)

Figure 1: The right sensor and appropriate processing can detect issues such as load or motor imbalance and ball-bearing failures, as well as vibrations that might predict another type of developing failure mode. (Image source: Analog Devices)

Helpfully, standards have been established for the sensor systems used in vibration monitoring. The ISO 2954:2012 standard, “Mechanical vibration of rotating and reciprocating machinery—Requirements for instruments for measuring vibration severity“ is a prime example. In such instruments, accelerometers are a core component. But in a typical design, the sensor’s signals are not used directly.

In modern systems, the first step in vibration monitoring is to bring the accelerometer’s signal into the digital domain using an ADC. Once digitized, the acceleration measurement is much less sensitive to electrical noise, and the need for precision analog signal conditioning can be eliminated. Vibration monitoring then requires several stages of filtering and pre-processing of the raw accelerometer data to eliminate noise and extract diagnostically useful information.

Accelerometer signal preprocessing requirements

The accelerometer signals first need to be high-pass filtered to remove any DC components, such as sensor bias or the effects of gravity. The filtered signal can then be used in two ways: one is to work with acceleration information directly, while the other is to work with vibrational velocity obtained by integrating the filtered signal over time. The resulting velocity signal also requires high-pass filtering to remove the need to know the system’s initial velocity (the constant of integration) when analyzing velocity information (Figure 2).

Figure 2: Raw accelerometer data needs to be pre-processed in order to remove bias, as well as integrated to yield a measurement of vibrational velocity before useful monitoring and diagnostic information can be extracted. (Image source: Richard A. Quinnell)

Figure 2: Raw accelerometer data needs to be pre-processed in order to remove bias, as well as integrated to yield a measurement of vibrational velocity before useful monitoring and diagnostic information can be extracted. (Image source: Richard A. Quinnell)

Depending on the application, a variety of analysis techniques can be applied to these acceleration and velocity signals to extract useful intelligence about the machinery’s condition. One of the most common and widely used techniques is to calculate the vibration’s root-mean-square velocity (RMS velocity) and determine its trend over time. As machines wear, they develop more space in which to move about, in turn causing their vibration’s velocity to increase. Monitoring RMS velocity trends, then, provides an indicator of wear that can be compared to pre-determined thresholds to identify a need for maintenance.

Acceleration can also be compared to pre-determined thresholds to detect bending or breakage in mechanisms, especially in rotating machinery. Such defects will typically manifest as periodic “spikes” in the signal. A trend of increasing acceleration or instability in the acceleration profile over time is also an indicator of wear and damage.

Spectral analysis yields additional insight

Transforming the acceleration and velocity data from the time domain to the frequency domain by using a fast Fourier transform (FFT) opens the door to even more detailed insights into machine condition. In rotating machinery, for instance, a strong signal at a single frequency that is related to the rotation rate will indicate an imbalance or a bent shaft. General looseness or a broken gear tooth on the other hand, will create an impact signal rich in harmonic content. A strong signal that is amplitude modulated by a lower frequency is a powerful diagnostic tool for gear mesh analysis.

Successful use of these various diagnostic techniques imposes a variety of requirements on the accelerometer supplying the source data. Its bandwidth, for instance, should be wide enough to easily capture modulation to basic motor rotation as well as higher-order harmonics. Synchronous AC motors typically rotate at 3600 revolutions per minute (rpm) and DC motors can range from 10 rpm to 7000 rpm or more, so a suitable sensor bandwidth might need to range as low as 0.1 hertz (Hz) or as high as five to ten kilohertz (kHz), depending on the machine’s design.

Sensitivity is also important. Depending on the sensor’s size, the only mounting point available for condition monitoring of moving machinery may be on the housing, well away from the vibration’s actual source inside the machine. This distance will attenuate the vibration, leading to a weak signal. As a result, both the sensor’s signal and the path from the sensor to the ADC need to be as low noise as possible to avoid having electrical interference—such as from the motor windings—swamp the signal of interest.

Vibration monitoring sensors need to have good stability over time and across temperature. Stability is especially important when utilizing RMS velocity trending as a diagnostic tool. Changes in the acceleration reading over time or temperature will accumulate during the integration that generates the velocity data, compromising the trend measurement.

In addition to these performance demands, there are several sensor attributes that are important from a system design perspective. The sensor should be as small as possible to maximize the options for placement on the machine being monitored. Low weight is also important to avoid having the sensor’s mass affect the machine’s vibration characteristics.

To minimize the need to use costly, low-noise coaxial cabling to connect an analog sensor to a digitizer, many accelerometers for industrial condition monitoring are combined with an ADC, communications circuitry, and possibly some digital signal processing into a sensor module. In such modules, both their small size and low power create an opportunity for battery and wireless operation, further simplifying placement and reducing wiring cost and complexity. Minimizing the sensor module’s total cost improves the cost-effectiveness of condition monitoring, enabling more opportunities to employ preventative maintenance.

MEMS accelerometers meet the performance, cost, and integration challenge

Advances in CMOS design and fabrication technology have allowed MEMS capacitive accelerometers to meet these performance and system design attributes for a wide range of industrial condition monitoring applications. Because they are fabricated using processes compatible with CMOS integrated circuit manufacturing, MEMS accelerometers gain a significant advantage over traditional piezoelectric accelerometers—the MEMS devices can integrate many of a full sensor module’s functions into a chip-sized package.

NOTE: It is important to point out at this stage that piezoelectric sensors still very much have a place and dominate in applications requiring extreme temperature tolerance or where vibrations above 50 g are likely.

The STMicroelectronics IIS3DWBTR triaxial MEMS accelerometer is a good example (Figure 3). This device contains three, ultra-wide bandwidth (DC to 6 kHz) acceleration sensors along with an ADC, a user-configurable digital filter chain, a temperature sensor, a 3 kilobyte (Kbyte) FIFO, and an SPI serial interface, all in a surface mount package that measures only 2.5 x 3 x 0.83 millimeters (mm). It is low power, operates from 2.1 to 3.6 volts and draws only 1.1 milliamperes (mA) during full operation. A 5 microampere (µA) sleep mode will automatically wake upon activity detection. It is also rugged, with a working temperature range from -40°C to +105°C and 10,000 g shock resistance. A selectable sensitivity (±2, ±4, ±8, or ±16 g) enables it to be tailored to a range of application requirements.

Figure 3: CMOS MEMS technology allows accelerometers such as the STMicroelectronics IIS3DWBTR to include an integrated ADC, digital filter, FIFO memory, and more in compact, low-power packages to minimize vibration monitoring costs. (Image source: STMicroelectronics)

Figure 3: CMOS MEMS technology allows accelerometers such as the STMicroelectronics IIS3DWBTR to include an integrated ADC, digital filter, FIFO memory, and more in compact, low-power packages to minimize vibration monitoring costs. (Image source: STMicroelectronics)

The advent of devices like the IIS3WDB has changed the range of opportunities for vibration condition monitoring. By integrating all the essential attributes of a sensor module at a low cost point, the devices minimize overall BOM costs to make monitoring cost-effective over a wider scope of applications. The small size and three-axis sensing (which eliminates the need for specific orientation) expand the options for sensor placement, including embedding inside the machinery. The digital interface allows simple wiring to connect the sensor to host processors for data collection and analysis, while the integrated pre-processing and FIFO buffer makes communications with the host less demanding. The low power demand opens the door to battery operation.

MEMS device designs can go further with respect to integration. In the same package size as the IIS3WDBTR, for instance, the STMicroelectronics ISM330DHCXTR packs both a three-axis accelerometer and a three-axis gyrometer for six degrees of motion sensing, as well as all the functionality that is in the IIS3DWBTR. Further, it includes an I2C interface, sensor hub capability, 9 Kbyte FIFO, a programmable finite state machine for data processing, and the core blocks for machine learning so that the device can adapt its operation to its unique installation.

Modules integrate data processing

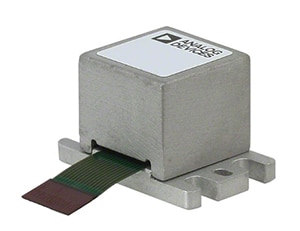

For even more demanding applications, MEMS sensor modules, complete with built-in processing, have become available in highly compact formats. For example, the Analog Devices ADIS16228CMLZ vibration sensor module is a full tri-axial, ±18 g MEMS accelerometer with an integrated ADC and a 512-point FFT for vibration analysis in the frequency domain—all in a 15 x 24 x 15 mm housing (Figure 4). The device also has programmable alarms for six spectral bands that are able to signal warnings or fault detection depending on the energy levels in those bands.

Figure 4: MEMS vibration sensor modules complete with built-in FFT processing and frequency-based fault detection, like the Analog Devices ADIS16628, are available in rugged, compact housings. (Image source: Analog Devices)

Figure 4: MEMS vibration sensor modules complete with built-in FFT processing and frequency-based fault detection, like the Analog Devices ADIS16628, are available in rugged, compact housings. (Image source: Analog Devices)

MEMS technology offers complete sensor systems capable of handling all the way up to ±50 g. The Analog Devices ADCMXL3021BMLZ, for example, has a 10 kHz sensor bandwidth, 220 kilo sample-per-second (kSPS) ADCs, digital filters, and user-configurable time and FFT-based conditional alarms. Yet even with all its built-in processing capability, the device typically requires only 30 mA at 3.3 volts.

These complete vibration sensor system modules offer many user configurable options for such attributes as pre-processing filter bandwidth, FFT windowing function, frequency band thresholding, temporal statistics, and the like. Using them effectively requires users to have a strong understanding of their system’s characteristics and the many vibrational analysis techniques they might apply. Similarly, developers seeking to create their own vibration monitoring systems using chip sensors like the IIS3DWB or the ISM330DHCX will need to know their target system characteristics and understand their processing options.

Start with an eval kit

To begin building this background, a development kit such as the STMicroelectronics STEVAL-STWINKT1 could be a good starting point (Figure 5). The kit’s module includes both the IIS3DWB and the ISM330DHCX, along with numerous other sensors and an Arm® Cortex®-M4 processor with floating-point unit to handle the additional processing. The module can be powered from the included Li-Ion battery and offers a built-in Bluetooth Low Energy radio as well as a Wi-Fi expansion card for wireless connectivity, making the kit suitable for use as a stand-alone condition monitoring sensor in field installations.

Figure 5: Development kits such as the STEVAL-STWINKT1 not only provide developers with accelerometers and other MEMS sensors to evaluate, they can work as stand-alone, off-the-shelf modules for industrial monitoring. (Image source: STMicroelectronics)

Figure 5: Development kits such as the STEVAL-STWINKT1 not only provide developers with accelerometers and other MEMS sensors to evaluate, they can work as stand-alone, off-the-shelf modules for industrial monitoring. (Image source: STMicroelectronics)

The kit comes fully supported with a complete set of firmware for developing condition monitoring and predictive maintenance applications. This includes middleware for vibration analysis in the time domain (RMS velocity and acceleration peaks) as well as in the frequency domain. The software is also compatible with the company’s DSH-PREDMNT web-based predictive maintenance dashboard for monitoring sensor data and device status. Sample implementations are available to give developers a roadmap for their own software design efforts.

Conclusion

While piezoelectric sensors still dominate in applications requiring extreme temperature tolerance or vibration regimes above 50 g, their size and need for discrete ADCs and preprocessing hardware (with associated cabling cost and complexity) have traditionally limited their application range to high-value equipment monitoring.

Instead, designers can utilize MEMS accelerometers that offer a compact, cost-effective alternative that simplifies deployment and expands the range of applications for vibration monitoring. Together with the ever-increasing performance these devices are offering, MEMS accelerometers are allowing designers to readily adopt the benefits of vibrational condition monitoring and predictive maintenance for machinery of all sizes.

Disclaimer: The opinions, beliefs, and viewpoints expressed by the various authors and/or forum participants on this website do not necessarily reflect the opinions, beliefs, and viewpoints of DigiKey or official policies of DigiKey.