Build Connected Intelligent Field Instruments Quickly with Comprehensive Solution Sets

Contributed By DigiKey's North American Editors

2023-11-07

To realize the full potential of Industry 4.0, designers need to acquire data from harsh environments and communicate that data reliably and securely to the control system. Although the key technology enablers exist to achieve this vision, designers in the past have been on their own in identifying and implementing effective solutions. Designers need solutions that simplify the implementation of the connected intelligent field instruments needed to achieve digital transformation in the process industry.

This article describes the use of a comprehensive solutions set from Analog Devices that offers an effective answer to the growing demand for connected intelligent field instruments.

Field instruments rely on four key functional capabilities

In industrial automation deployments, field instruments comprise the collection of signal processing devices ensuring reliable data and control exchange between end sensors and actuators in the field, and the host systems used to manage those devices and their data. In a typical application, these instruments need to support four key functional capabilities:

- Provide interfaces with sensors or actuators connected through analog-to-digital converters (ADCs) or digital-to-analog converters (DACs)

- Provide microcontroller units (MCUs) for signal conditioning and end-device control

- Provide the power, isolation, and supervision needed for instrument operation and safety

- Provide interfaces to the various connectivity options required for reliable and secure exchange of data and control information

Designers have addressed these functional requirements for a typical field instrument by finding the needed ADCs, MCUs, power, and connectivity devices to support each specific sensor or actuator-based application (Figure 1).

Figure 1: When creating field instruments, designers have addressed the basic requirements for acquiring sensor data or controlling transducers by using available ADCs, DACs, MCUs, and additional support devices. (Image source: Analog Devices)

Figure 1: When creating field instruments, designers have addressed the basic requirements for acquiring sensor data or controlling transducers by using available ADCs, DACs, MCUs, and additional support devices. (Image source: Analog Devices)

With the more significant challenges of Industry 4.0, field instrument designers face an expanding set of requirements for greater edge intelligence, safety, and security while continuing to provide accurate and reliable data.

Industry 4.0 drives the need for more advanced capabilities

At the sensor or actuator interface, a greater number and variety of high-resolution, high-bandwidth sensors necessitate effective analog front-end (AFE) solutions. The processing demands of these instruments rise accordingly, driven by extensive sensor signal acquisition and conditioning demands. Furthermore, the drive for greater edge intelligence warrants advanced processors that can efficiently execute artificial intelligence (AI) algorithms at the edge, boosting field instrument efficiency and enhancing industrial safety. The security of these instruments remains paramount in the face of an expanding array of threats.

With increased capabilities, advanced field instruments require higher data bandwidth and power delivery compared to legacy 4-20 milliamp (mA) current loop devices, which typically offer power delivery to instruments of 1.2 kilobits per second (Kbits/s) and less than 40 milliwatts (mW). 10BASE-T1L supports data bandwidth of 10 megabits per second (Mbits/s) and power delivery up to 60 watts or 500 mW in Zone 0, encouraging intrinsically safe use cases with Ethernet-APL. Furthermore, 10BASE-T1L/Ethernet-APL provides this performance over single twisted pair cable while enabling reuse of existing installed cable.

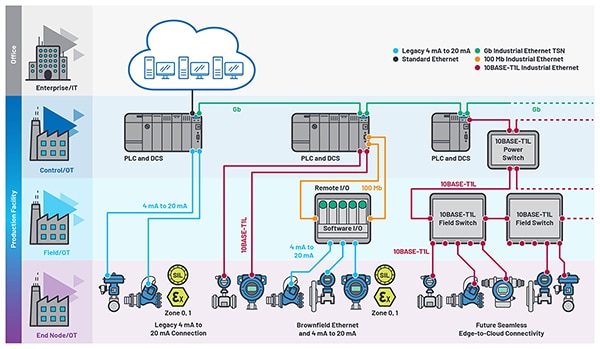

Even as industrial systems involve more demanding communications requirements, the need to support legacy field instruments and emerging Industry 4.0 applications remains. As a result, designers must respond with intelligent field instrument designs for a combination of existing brownfield applications and new greenfield systems (Figure 2).

Figure 2: When designing intelligent field instruments, designers face the challenge of responding to emerging power and data bandwidth requirements and supporting existing industrial applications. (Image source: Analog Devices)

Figure 2: When designing intelligent field instruments, designers face the challenge of responding to emerging power and data bandwidth requirements and supporting existing industrial applications. (Image source: Analog Devices)

Using a set of advanced devices from Analog Devices, designers can quickly address requirements for the intelligent field instruments used for existing and emerging industrial automation systems.

Meet requirements for advanced field instruments with a comprehensive set of devices

A typical field instrument must satisfy a range of requirements. A typical pressure sensor transmitter demonstrates how designers can readily meet these requirements in their own applications (Figure 3).

Figure 3: A pressure sensor transmitter high-level design illustrates basic requirements for a typical intelligent field instrument’s sensor interface, processor, power, and connectivity functional capabilities. (Image source: Analog Devices)

Figure 3: A pressure sensor transmitter high-level design illustrates basic requirements for a typical intelligent field instrument’s sensor interface, processor, power, and connectivity functional capabilities. (Image source: Analog Devices)

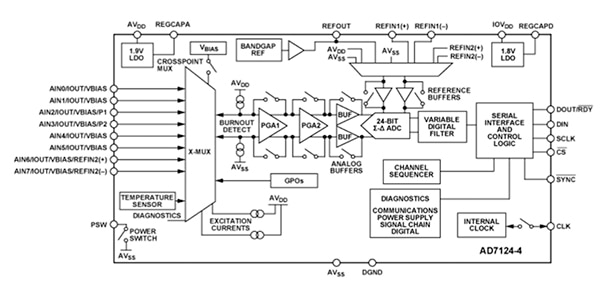

In the pictured pressure sensor transmitter design, the signal chain must provide an excitation current to the resistive-bridge pressure sensor and measure the differential voltage generated as the sensor reacts to pressure. Here, a single integrated device such as Analog Devices’ AD7124 or AD4130 AFEs simplifies the sensor interface by providing excitation current as part of a complete multichannel signal chain with a digital output (Figure 4).

Figure 4: The AD7124 AFE provides the complete multichannel signal chain required to generate digital data from most active and passive sensors. (Image source: Analog Devices)

Figure 4: The AD7124 AFE provides the complete multichannel signal chain required to generate digital data from most active and passive sensors. (Image source: Analog Devices)

To complete the sensor subsystem, designers can use an MCU from Analog Devices’ ADuCM36x family to manage the AFE and perform additional signal processing, calibration, and compensation. For example, designers can use the ADuCM36x MCU’s integrated 24-bit ADC to convert readings from a temperature sensor to provide temperature compensation of the resistive-bridge sensor (Figure 4).

For more extensive processing and overall management of the field instrument, designers can incorporate a high-performance Arm® Cortex®-M4 MCU such as Analog Devices’ MAX32675 or MAX32690, while new AI microcontrollers, such as the multi-award winning MAX78000 family, ensure the highest efficiency execution of neural networks at the edge. Isolated from the sensor subsystem by an Analog Devices’ ADUM1440 digital isolator, the high-performance MCU manages field instrument operation, additional peripherals, and connectivity.

Designed for industrial automation, these MCUs meet different specialized application requirements. For example, the MAX32675 is well-suited to 4-20 mA current loop applications, while the MAX32690 integrates an advanced Bluetooth 5.2 low energy (LE) radio for wireless applications and sufficient memory to support large communication stacks such as Profinet. Both processors address growing security concerns by offering an integrated true random number generator, an advanced encryption standard (AES) engine, secure nonvolatile key storage, and secure boot.

To supply regulated power to the devices in a field instrument, designers would typically include a low dropout (LDO) regulator such as Analog Devices’ ADP162, as well as a DC-DC step-down switching regulator like Analog Devices’ ADP2360. Ensuring a correct supply voltage to the processor subsystem is essential for intelligent field instrument designs operating in electrically noisy environments. Using Analog Devices’ ADM8323 supervisor, designers can ensure the supply voltage remains above a preset voltage threshold.

During power-up, power-down, and brownout events, the ADM8323 asserts a signal that holds the MCU in a reset state. When power returns above the threshold level, the ADM8323 releases the reset. At that point, MCUs that support secure boot, such as the MAX32675 and MAX32690, confirm the authenticity of the program code before proceeding. To confirm that code execution continues normally, designers can use the ADM8323’s windowed integrated watchdog timer.

Acquiring sensor data and reliably executing code are fundamental aspects of the operation of an intelligent field instrument. At the application level, reliable communication is critical. For years, intelligent connected field instruments have relied on 4-20 mA current loop devices and data exchange using the phase continuous frequency shift keying (FSK) HART modem protocol. Designers can readily support existing current loop and HART protocol interfaces using Analog Devices’ AD5421 4-20 mA DAC and AD5700 HART modem devices.

Industrial automation solutions require higher voltage levels and more bandwidth than earlier methods can support, driving a need for connectivity options like the 10BASE-T1L physical layer standard. Designers can quickly implement 10BASE-T1L connectivity using Analog Devices’ ADIN1100 or ADIN1110. While the ADIN1100 offers a physical (PHY) layer transceiver for designs, the ADIN1110 integrates both a PHY transceiver and a media access control (MAC) interface, enabling usage with low-power processors without an integrated MAC.

Extend and enhance field instruments for specialized requirements

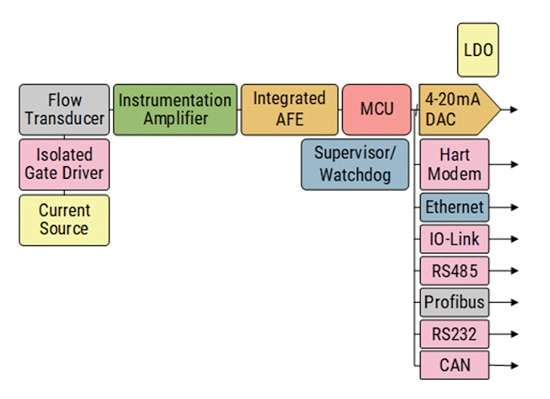

By adding or substituting a few components, designers can extend and enhance the same pressure sensor design from Figure 3 to create the connected field instrument required for their specific application. For example, a design for an electromagnetic flow transmitter might use the same overall architecture, merely adding and removing a few components as needed (Figure 5).

Figure 5: Designers can quickly respond to new sensor interface requirements, such as those for the electromagnetic flow transmitter shown here, while reusing elements of an existing field instrument design. (Image source: Analog Devices)

Figure 5: Designers can quickly respond to new sensor interface requirements, such as those for the electromagnetic flow transmitter shown here, while reusing elements of an existing field instrument design. (Image source: Analog Devices)

For this application, many of the same components satisfy the overall requirements, but a different sensor interface is required. Designers can meet the new sensor interface requirements using a suitable instrumentation amplifier such as Analog Devices’ AD8422, an ADP2441 DC-DC regulator, and an ADuM4121 isolated gate driver to provide the constant-current excitation source needed for the flow transducer.

Other available building blocks address emerging specialized requirements. For example, connected, intelligent field instruments might need encryption and authentication capabilities to protect data from disclosure and ensure the integrity of control instructions passed from a host to the instrument, meeting the latest IEC 62443 requirements. In this case, designers could add Analog Devices’ ultra-low power MAXQ1065 security co-processor to compute a session key for use in AES message encryption.

Conclusion

Sophisticated industrial automation applications build on the capabilities of intelligent field instruments and can support greater numbers of varied sensors and actuators. To design those instruments effectively, designers can now draw on a comprehensive set of devices to support more demanding sensor interfaces, processors, power, and connectivity requirements.

Disclaimer: The opinions, beliefs, and viewpoints expressed by the various authors and/or forum participants on this website do not necessarily reflect the opinions, beliefs, and viewpoints of DigiKey or official policies of DigiKey.