Use a Portfolio of Low-Power Microcontrollers to Simplify Healthcare and Industrial IoT Design

Contributed By DigiKey's North American Editors

2024-10-10

Developers of low-power designs for industrial, healthcare, and diverse Internet of Things (IoT) applications face a continued demand for microcontroller-based solutions that offer extensive functionality without compromising tight power budgets. As development proceeds, they frequently risk crossing maximum power thresholds to satisfy specialized functional requirements.

This article shows how Analog Devices' portfolio of ultra-low-power microcontrollers can satisfy these requirements.

Meeting requirements of specialized applications

Designers must satisfy a core set of high-performance, low-power consumption requirements to respond effectively to customer expectations. In application areas as diverse as healthcare, industrial, and IoT, these core requirements have typically dominated design decisions and guided the development of hardware platforms that are essentially indistinguishable. As a result, designers can quickly apply hardware and software design experience gained in one application area to address the basic needs of another.

With the rising demand for increasingly sophisticated products across these areas, it is more challenging for designers to meet the particular demands of specialized applications without sacrificing their ability to satisfy the core requirements. Application segments have begun to differentiate sharply, with unique connectivity, security, and artificial intelligence (AI) requirements.

Driven by these changing needs, the concept of a common hardware platform has evolved to enable designers to meet the core requirements for high performance and low power while relying on a familiar processor set augmented by specialized capabilities.

Processor foundation tailored for specialized capabilities

Built around the ultra-low-power Arm® Cortex®-M4 with a floating point unit (FPU), members of Analog Devices’ portfolio of ultra-low-power microcontrollers offer designers a familiar platform capable of meeting core power and performance requirements.

To satisfy the unique requirements of different application areas, Analog Devices tailors this foundation with specialized capabilities in four portfolio members, including:

- The MAX32655 targets applications requiring Bluetooth Low Energy (BLE) connectivity and extended battery life while providing sufficient memory and performance.

- The MAX32690 targets applications requiring BLE, robust performance, and extensive memory.

- The MAX32675C targets applications with mixed-signal requirements needed for industrial and medical sensors.

- The MAX78000 meets the emerging demand for intelligent edge devices.

Addressing connectivity

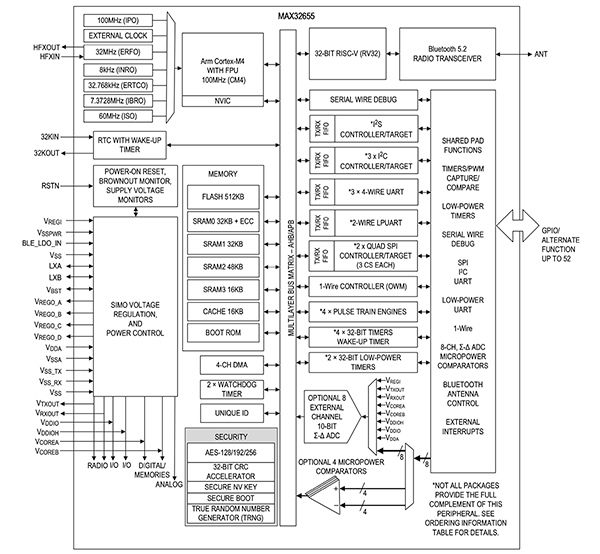

Analog Devices’ MAX32655 microcontroller integrates a 100 megahertz (MHz) Arm Cortex-M4 with FPU, 512 kilobytes (Kbytes) of flash, 128 Kbytes of static random-access memory (SRAM), and 16 Kbytes of instruction cache to provide the effective combination of processor performance and memory storage required in typical low-power applications. Beyond this processing subsystem, the device adds a comprehensive set of functional blocks for the security, power management, timing, and digital and analog peripherals typically needed in asset tracking, wearables, and healthcare monitoring devices (Figure 1).

Figure 1: With its extensive set of integrated peripherals, the MAX32655 microcontroller supports a broad array of applications that require Bluetooth connectivity, high-performance processing, and optimized power utilization. (Image source: Analog Devices)

Figure 1: With its extensive set of integrated peripherals, the MAX32655 microcontroller supports a broad array of applications that require Bluetooth connectivity, high-performance processing, and optimized power utilization. (Image source: Analog Devices)

To meet the varied Bluetooth connectivity requirements of different applications, the MAX32655 provides dedicated hardware and software to support a complete set of Bluetooth 5.2 features. Along with a Bluetooth 5.2 radio, the microcontroller integrates a dedicated 32-bit RISC-V coprocessor to handle timing-critical Bluetooth processing tasks. This Bluetooth subsystem meets emerging performance demands, supporting 2 megabits per second (Mbits/s) high-throughput mode and a long-range mode with rates of 125 kilobits per second (Kbits/s) and 500 Kbits/s. Two device pins allow developers to simply connect an off-chip antenna in Bluetooth-enabled designs. Completing its Bluetooth 5.2 functionality and providing application support, the device’s run-time Bluetooth stack extends across the Arm Cortex-M4 with FPU, RISC-V, and radio (Figure 2).

Figure 2: Running on the MAX32655’s Arm Cortex-M4 with FPU, RISC-V, and radio, a full Bluetooth 5.2 stack supports a complete set of features for direction finding, high-throughput communication, and long-range operation. (Image source: Analog Devices)

Figure 2: Running on the MAX32655’s Arm Cortex-M4 with FPU, RISC-V, and radio, a full Bluetooth 5.2 stack supports a complete set of features for direction finding, high-throughput communication, and long-range operation. (Image source: Analog Devices)

For applications with robust performance and memory requirements, Analog Devices’ MAX32690 microcontroller offers a 120 MHz Arm Cortex-M4 with FPU along with 3 Mbytes of flash, 1 Mbyte of SRAM, and 16 Kbytes of cache memory. In addition to the analog comparators and digital peripherals in the MAX32655, the MAX32690 integrates a HyperBus/Xccela bus interface for high-speed execution from external flash and SRAM when memory requirements exceed on-chip resources. Like the MAX32655, the MAX32690 integrates a 32-bit RISC-V processor, which is available for standalone processing and Bluetooth processing support.

To help developers optimize power consumption, each of the four microcontrollers mentioned earlier supports several low-power operating modes. In the MAX32655 and MAX32690, the low power modes include:

- Sleep, where the Arm Cortex-M4 with FPU (CM4) and 32-bit RISC-V (RV32) are in sleep mode, but peripherals remain on

- Low-Power Mode (LPM), where the CM4 is in sleep state with state retention while the RV32 remains active to move data from enabled peripherals

- Micro Power Mode (UPM), where the CM4, RV32, and certain pins retain state, but a watchdog timer, analog comparators, and low-power UART remain available to wake the microcontroller

- Standby, where the real-time clock remains on, and all peripherals retain state

- Backup, where the real-time clock remains on, and system memory retains its state

In addition, the MAX32655 offers a Power Down Mode (PDM) designed for use during end-product storage and distribution. In PDM mode, the MAX32655 is powered off, but an internal voltage monitor remains operational. As a result, end users can quickly power up MAX32655-based products by removing a protective battery tab or otherwise applying power to the product.

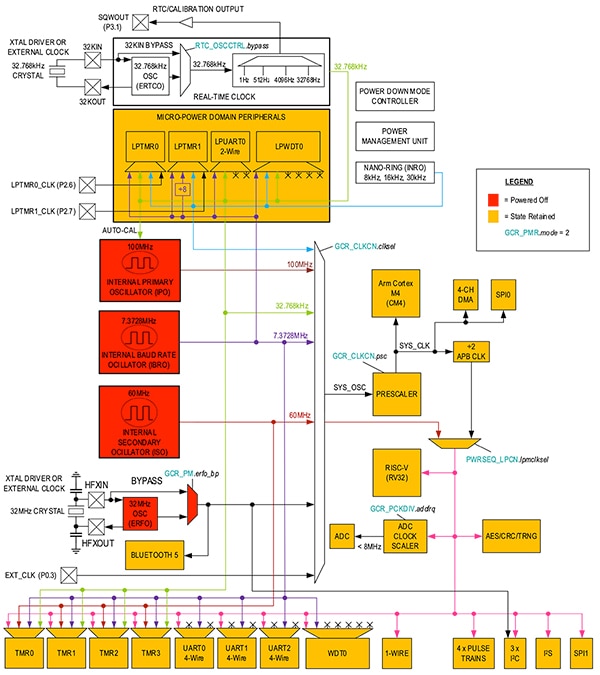

These operating modes can offer significant power savings even with ultra-low-power microcontrollers by selectively powering down different hardware blocks. For example, the MAX32655 in normal active operating mode consumes only 12.9 microamps per megahertz (μA/MHz) at 3.0 volts. In standby mode, it retains its state or completely powers down several blocks to achieve a power consumption of only 2.1 μA at 3.0 volts, while enabling the device to resume operation in only 14.7 microseconds (μs) (Figure 3).

Figure 3: The MAX32655 microcontroller’s different power modes, such as standby mode shown here, can retain state or completely power down different hardware subsystems to reduce power consumption while maintaining operational capability. (Image source: Analog Devices)

Figure 3: The MAX32655 microcontroller’s different power modes, such as standby mode shown here, can retain state or completely power down different hardware subsystems to reduce power consumption while maintaining operational capability. (Image source: Analog Devices)

Along with their low-power operating capabilities, these devices' high level of integration helps developers reduce design complexity and meet the requirements for a minimal footprint. For example, the MAX32655’s integrated single-inductor multiple-output (SIMO) switch-mode power supply requires only a single inductor/capacitor pair. As a result, developers can more easily create compact designs powered by a single lithium cell to meet the package requirements in applications such as asset tracking, wearables, hearables, and similar space-constrained products.

For a true wireless stereo (TWS) earbud design, for example, developers can implement an effective solution using the MAX32655 with minimal additional components beyond a codec and battery power management. Combining a MAX32655 with these devices and a DS2488 1-wire dual-port link provides a complete design for a TWS earbud and its charging cradle (Figure 4).

Figure 4: The MAX32655 microcontroller’s integrated functionality enables designs with a minimal footprint and bill of materials, requiring few additional devices beyond a codec, a power management device, and an interface device such as the DS2488 1-wire to implement a complete TWS earbud and charging cradle solution. (Image source: Analog Devices)

Figure 4: The MAX32655 microcontroller’s integrated functionality enables designs with a minimal footprint and bill of materials, requiring few additional devices beyond a codec, a power management device, and an interface device such as the DS2488 1-wire to implement a complete TWS earbud and charging cradle solution. (Image source: Analog Devices)

To speed evaluation and prototyping with these microcontrollers, developers can take advantage of multiple Analog Devices development resources, including:

- MAX32655 evaluation kit (MAX32655EVKIT)

- MAX32655 feather board (MAX32655FTHR)

- MAX32690 evaluation kit (MAX32690EVKIT)

- MAX32690 Arduino form-factor development platform (AD-APARD32690-SL)

A more effective solution to mixed-signal design requirements

While the MAX32655 and MAX32690 address the need for compact battery-powered Bluetooth-capable products, Analog Devices’ MAX32675C low-power mixed-signal microcontroller addresses the specialized requirements for medical and industrial sensor applications.

The MAX32675C offers low power consumption at start up and during run time, along with the high levels of integration increasingly required in these applications. It combines its 12 MHz Arm Cortex-M4 processor and FPU with 384 Kbytes of flash, 160 Kbytes of SRAM, and 16 Kbytes of cache, as well as a precision analog front-end (AFE) and HART modem (Figure 5).

Figure 5: The MAX32675C microcontroller’s integrated AFE and HART modem provide the subsystems needed to meet the requirements for a small footprint and low power in industrial and medical sensors. (Image source: Analog Devices)

Figure 5: The MAX32675C microcontroller’s integrated AFE and HART modem provide the subsystems needed to meet the requirements for a small footprint and low power in industrial and medical sensors. (Image source: Analog Devices)

Communicating with the processor over an internal serial peripheral interface (SPI), the AFE provides a set of peripherals typically required in industrial and medical sensor applications including a 12-bit digital-to-analog converter (DAC), and dual high-precision delta-sigma analog-to-digital converters (ADCs) that can be configured for 16-bit or 24-bit operation. Each ADC has a dedicated 1x to 128x low-noise programmable gain amplifier (PGA) driven by a 12-channel input multiplexer that can be configured for 12-channel single-ended or 6-channel differential operation.

The MAX32675C is particularly well-suited to meeting demand for low-power industrial field instruments based on 4-20 milliamp (mA) sensors and transmitters. In fact, this microcontroller is explicitly designed to never exceed power restrictions in 4-20 mA applications, solving a common problem during startup where microcontrollers have had difficulty maintaining power limits.

To support an essential requirement of many existing industrial control systems, the AFE provides a complete HART modem, simplifying the implementation of industrial field instruments over a 4-20 mA current loop (Figure 6).

Figure 6: The MAX32675C microcontroller’s AFE includes a dedicated HART modem to support existing 4-20 mA field instruments in typical industrial applications. (Image source: Analog Devices)

Figure 6: The MAX32675C microcontroller’s AFE includes a dedicated HART modem to support existing 4-20 mA field instruments in typical industrial applications. (Image source: Analog Devices)

With the MAX32675C, industrial application developers can easily configure and control field instruments through the HART modem’s SPI connection to the Arm Cortex-M4.

Along with documentation and other development resources, Analog Devices offers the MAX32675EVKIT MAX32675C evaluation kit to help speed testing and prototype development.

Meeting emerging requirements for edge AI

To build effective applications in a growing number of areas, developers must implement edge devices that efficiently execute AI algorithms for intelligent time-series processing or recognition of objects, words, or faces. Analog Devices’ MAX78000 is designed specifically to support these capabilities while maintaining the fundamental requirement for low power consumption.

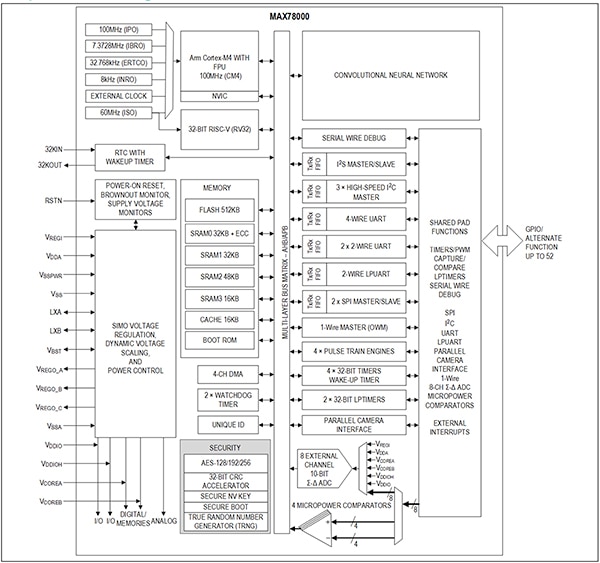

Like the ultra-low-power microcontrollers described earlier, the MAX78000 (Figure 7) builds on an Arm Cortex-M4 with an FPU processor, 512 Kbytes of flash, 128 Kbytes of SRAM, and 16 Kbytes of cache to meet the core application execution requirements. To support edge AI solutions, the MAX78000 augments its processing subsystem with a pair of additional resources, including:

- A 32-bit RISC-V coprocessor that provides the system with ultra-low power consumption signal processing capabilities

- An integrated hardware-based convolutional neural network (CNN) accelerator to meet the emerging demand for edge AI devices

Figure 7: Along with its Arm Cortex-M4 with FPU and 32-bit RISC-V processors, the MAX78000 microcontroller integrates a CNN accelerator to boost inference performance in edge AI applications. (Image source: Analog Devices)

Figure 7: Along with its Arm Cortex-M4 with FPU and 32-bit RISC-V processors, the MAX78000 microcontroller integrates a CNN accelerator to boost inference performance in edge AI applications. (Image source: Analog Devices)

The MAX78000 supports the same low-power operating modes and power-down mode described earlier for the MAX32655, with the CNN remaining available through sleep and low-power modes, state retention in micro power, standby, and backup modes, and a power-down mode for use during end-product storage and distribution.

As with the other microcontrollers discussed here, the MAX78000’s high level of integration helps developers meet the requirements for a minimal bill of materials (BOM) and end-product size. With the device’s integrated ADC and signal processing capabilities, developers can use the MAX78000 with few additional components to quickly implement edge AI applications such as keyword spotting (KWS) or face identification (FaceID).

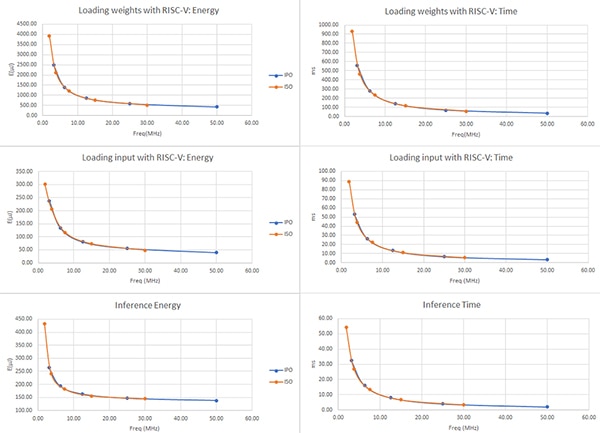

Besides simplifying edge AI implementation, the MAX78000’s combination of multiple power modes, dual processors, and hardware-based CNN allows developers to achieve fast inference speed with minimal power consumption. Analog Devices engineers closely examined performance in a study of power-optimized applications on the MAX78000.1

As part of this study, the engineering team measured energy consumption and time for loading model weights (kernels), loading input data, and performing inference for typical edge AI applications. For example, in a case study of KWS with 20 keywords (KWS20), the results showed that developers could run the Arm processor alone to reduce loading time and energy consumption while running in different MAX78000 power operation modes (Figure 8).

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Figure 8: A KWS20 case study application showed that a higher clock speed resulted in lower energy consumption due to shorter loading times, particularly when only the Arm processor was used. (Image source: Analog Devices)

The study also examined the effect on energy consumption and time when the Arm processor and RISC-V processor were asleep during idle time, with the RISC-V processor waking only long enough to perform loading and manage the CNN. Here, the study compared performance using two different clock sources: the MAX78000’s internal primary oscillator (IPO) at 100 MHz versus the lower power but slower internal secondary oscillator (ISO) at 60 MHz. In this result, a reduction in clock frequency dramatically increased energy consumption associated with both loading and inference due to the longer completion time required for each (Figure 9).

Figure 9: In the KWS20 case study, using higher clock frequencies with the RISC-V processor alone for loading and CNN management application resulted in lower energy consumption due to shorter loading and inference times. (Image source: Analog Devices)

Figure 9: In the KWS20 case study, using higher clock frequencies with the RISC-V processor alone for loading and CNN management application resulted in lower energy consumption due to shorter loading and inference times. (Image source: Analog Devices)

Based on their study, the Analog Devices team noted that developers could achieve fast inference with minimal power consumption by running at higher clock rates, particularly with the high-performance Arm processor, employing judicious use of the MAX78000’s power operating modes, and retaining kernels in memory to avoid energy lost during extended loading times.

For developers creating their own edge AI solutions, Analog Devices offers a comprehensive set of MAX78000 development resources, including its MAX78000EVKIT evaluation kit and MAX78000FTHR feather board. Along with an onboard digital microphone, motion sensors, color display, and multiple connection options, the MAX78000EVKIT includes a power monitor feature to help developers optimize power consumption.

For software development, Analog Devices’ MAX78000 CNN toolset repository offers documentation, development guides, training videos, and software code supporting the evaluation kit and feather board.

Conclusion

Building on an efficient processor subsystem foundation, Analog Devices presents a set of ultra-low-power microcontrollers that integrates the features and capabilities designed specifically to support the unique requirements of applications such as wearables, hearables, asset tracking, industrial and medical sensors, and edge AI. Using these microcontrollers and supporting resources, developers can quickly implement designs that meet the specialized needs of diverse low-power applications.

Reference:

Disclaimer: The opinions, beliefs, and viewpoints expressed by the various authors and/or forum participants on this website do not necessarily reflect the opinions, beliefs, and viewpoints of DigiKey or official policies of DigiKey.