Buck Converters - A Staircase for Voltage

2023-12-26 | By Antonio Velasco

License: Public Domain Stepper

A very important component in electronics is the buck converter: an amalgamation of several parts to serve a simple purpose: stepping-down voltage. It serves as a nice staircase for you to go down and provides a perfect solution for power electronics. They're typically used in a wide array of applications, from charging batteries or voltage regulation, and ensuring motors get the appropriate voltage.

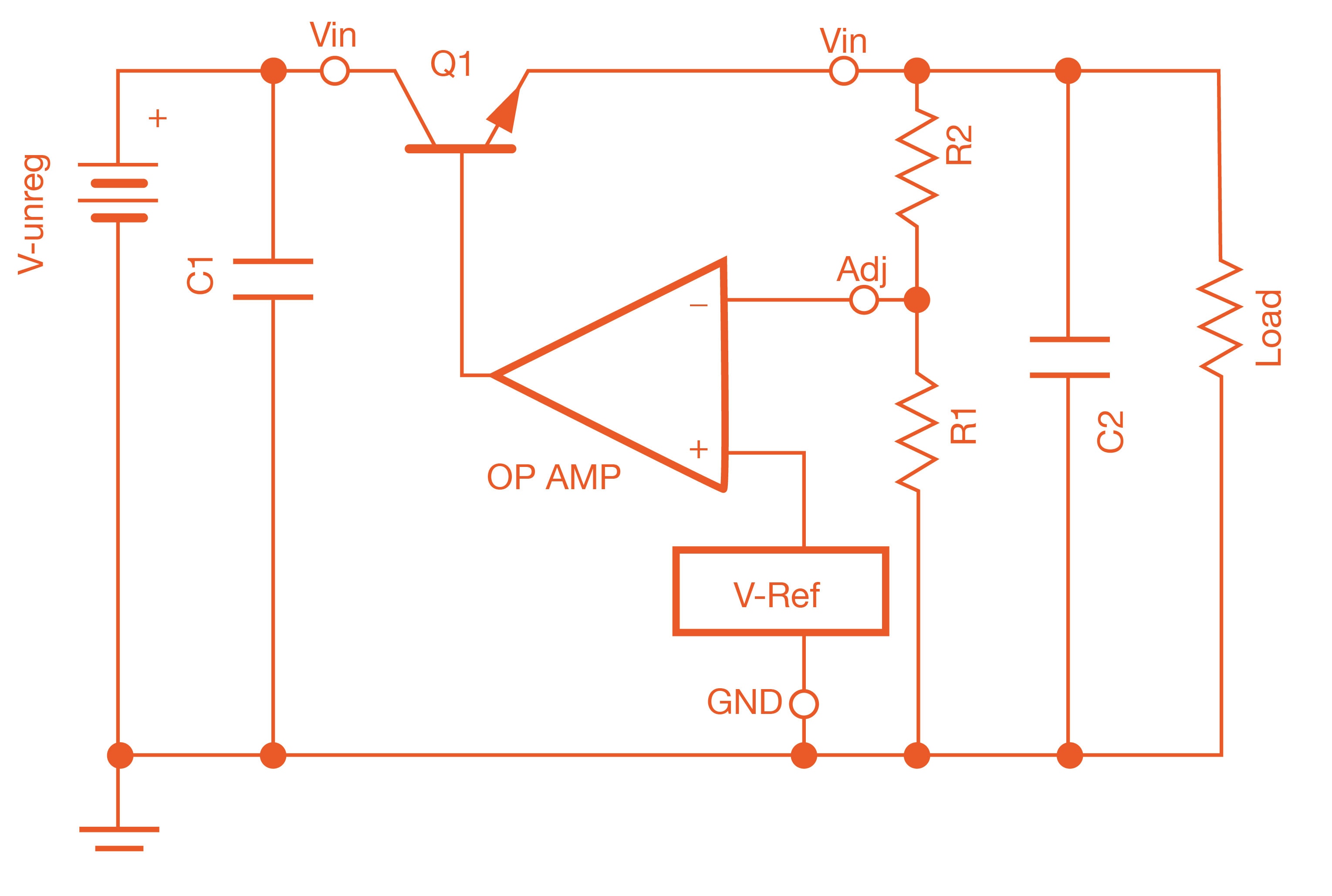

In my previous Engineering 7A blog, I depicted this diagram of our electrical circuit:

You’ll notice that the servo can’t be connected directly to the battery without worrying about burning it out. The buck converter essentially serves as a DC-to-DC converter to output specifically what the servo needs, and can be adjusted by a potentiometer on it. Now that it's a little clearer what it is, let's go behind the curtain and see how it works.

The Buck Converter's Science

As mentioned, buck converters are essentially an amalgamation of several parts. This mainly includes a diode, switching transistor, capacitor, and inductor. If you wish to read more about each, I've linked a blog that I've written for each!

Buck Converters operate through PWM or Pulse-Width modulation. It essentially controls the duty cycle of a switching transistor, thus regulating the voltage. This sounds pretty weird, so let's break it down:

1. A Buck Converter receives a high input voltage

2. A switching transistor is controlled by a PWM signal, rapidly switching on and off depending on the frequency

3. This rapid switching on and off provides current to flow into an inductor, thus storing energy in a magnetic field, which will then flow out in one direction due to a diode

4. An output capacitor will then receive this current and smooth out voltage ripples, thus allowing the output voltage to be filtered and regulated depending on what the buck converter dictates.

Another very cool factoid is that buck converters will monitor their output voltage and utilize a control loop to make adjustments as necessary. The duty cycle of the PWM is typically the part affected by this feedback, ensuring that the voltage remains within a desired range if input voltage spikes or the conditions change.

Additionally, what makes the buck converter unique is that the majority of the power that goes in will be output, resulting in extremely high efficiency.

Applications of Buck Converters

Given their extreme usefulness, buck converters are used in a multitude of applications. This includes everything from any battery-powered device (to control the battery voltage and thus maximize battery life and minimize heat generation) and even solar panels (which produce varying voltage levels as it depends on sunlight intensity). Controlling the amount of power that you receive is essential for maintaining your components and ensuring that they last a very long time.

If you wish to use a buck converter, ensure that you choose the correct buck converter module by checking the input/output voltage requirements and the current ranges. Ensure that you adjust the voltage to what you require as well through either the potentiometer or a digital display. This is something that I forgot to do, and I ended up burning out a servo motor as a result! If your buck converter doesn't have a digital display, it can be hard to figure out what the output is--this is where you can use a multimeter to check! Finally, if you're working with a lot of power, maybe investigate providing sufficient cooling for the buck converter to not burn out or damage your component.