C0G MLCC 為車載充電器提供設計優勢

資料提供者:DigiKey 北美編輯群

2025-06-03

電動車駕駛理應無需擔心充電效率和熱穩定性,他們單純想要高度可靠的運輸,有最佳的每次充電續航力,以及最少的維護與修理。車廠則希望車載充電器 (OBC) 盡可能越小越好。要滿足駕駛與車廠雙方的期望,會是個設計難題,但透過具有 C0G 特性的積層陶瓷電容 (MLCC),目標已逐漸達成。

C0G 也稱為 NP0,屬於 Class 1 介電陶瓷電容,具有極其穩定的電容量:接近零變化、最大容許誤差為 ±30 ppm/°C。這可提供優異的操作體驗,因為不太會隨著溫度、電壓或老化而有太多變化,非常適合精密電路和可靠型應用,例如電動車的 OBC。相較之下,Class II MLCC (如 X7R) 則有 ±15% 的漂移,而薄膜電容通常會以 ±2% 的漂移運作。

OBC 屬於高壓 AC/DC 轉換器,可安全有效地利用電網電力對電動車電池充電。C0G MLCC 在電源轉換和電磁干擾 (EMI) 濾波上具有高精度、高穩定性功能,因此備受推崇。可用於 LLC 諧振腔電路、電壓暫態緩衝電路、高頻 EMI 抑制濾波器、DC 偏壓敏感控制電路,以及閘極驅動器和輔助電源供應器。

由於 EV OBC 現在通常具有 22 kW 的輸出功率,諧振電路功能用的電容必須可耐受高電壓並具有低損耗,以緊湊的外形承受更高的功率密度。C0G MLCC 在確保整體系統效率和可靠性方面發揮關鍵作用,因此是設計時極具吸引力的方案選項。

C0G 的優勢

具有 C0G 特性的 MLCC,比起傳統薄膜電容,更可在這些應用中發揮關鍵優勢。安裝面積大幅縮小、發熱也有所抑制,且傳輸效率有所提升,因此設計人員可利用這些優勢,達到更小且更強大的 OBC。

OBC 功率級的切換會產生 EMI,而此 EMI 更會受到碳化矽 (SiC) 和氮化鎵 (GaN) 等寬能隙半導體進一步放大。這些材料能以高效率達到超快速切換,但也會產生劇烈的電壓瞬變。這些通常稱為隨時間變化的高壓 (dv/dt) 事件,可能會超過 50 kV/μs,比傳統的矽 MOSFET 設計高出許多。

C0G 特性的 MLCC 具有本質穩定性、非壓電性,且在高頻應力下不易發生熱漂移或電漂移。擅長脈衝處理且具有低 ESL,非常適合緩衝電路和共模濾波。

C0G MLCC 具有極低的耗散因數和高品質 (Q) 電容量。這個組合可確保最小的能量損耗並達到穩定的諧振行為,進而降低熱應力並提高功率密度。與 X7R/X5R Class II 介電質 MLCC 相比,具有更優異的電氣穩定性,可提供零壓電雜訊,並可確保低耗散因數和高 Q 值效能,這對於高頻切換應用來說相當關鍵。

在緩衝網路和 EMI 濾波器中,高 Q 值元件有助於確保精確的阻抗特性、增強暫態抑制和雜訊濾波效果。對於 RF 系統和精密類比電路來說,高 Q 值可支援窄頻選擇性和訊號完整性,可促成更精確的濾波和頻率控制。

由於等效串聯電阻 (ESR) 低於薄膜電容,因此可減少自體發熱,有助於延長使用壽命。此外,隨著元件數量減少,使用 C0G MLCC 可延長 OBC 應用的故障前平均時間 (MTTF)。

C0G MLCC 對電動車駕駛與車主帶來的影響包括增進充電體驗、車輛可靠性和對製造品質的整體感受。C0G MLCC 有助於在極端條件下達到熱可靠性、提高能效和續航里程信心、享受平穩寧靜的駕馭、降低 EMI,並可讓駕駛安心。

OBC 的設計考量

C0G MLCC 將穩定性、低損耗和緊湊尺寸以獨特方式結合在一起,是高速和高精密電路的理想選擇。但是,設計人員在決定要使用 C0G MLCC、X7R MLCC 還是薄膜電容時,必須進行權衡取捨。

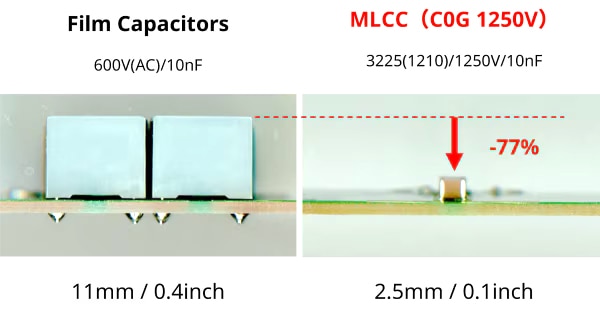

薄膜電容可提供更大的電容量,以達到高電壓和儲能,但通常是較昂貴且笨重的選擇 (圖 1)。X7R MLCC 比薄膜替代品更緊湊、更具成本效益,但其電容量在 DC 偏壓下會受到明顯影響,因此需要降額才能達到電壓穩定性。

圖 1:典型的 600 V 薄膜電容 (左) 和 3225 封裝的高壓 C0G MLCC 的尺寸比較。(圖片來源:TDK Corporation)

圖 1:典型的 600 V 薄膜電容 (左) 和 3225 封裝的高壓 C0G MLCC 的尺寸比較。(圖片來源:TDK Corporation)

C0G MLCC 比起 X7R 的價格略高,但可確保更高的穩定性和更好的效能,而且無需降額。成本上的差異,至少能透過整體元件數量的減少,進而降低總材料花費而達到部分抵銷。

在電動車 OBC 或其他功率敏感型車用系統的設計中採用 C0G MLCC 時,必須謹慎挑選元件。廠商的規格可能類似,但在 ESR、ESL 和結構上有所差異,就會影響電路調諧。重要的是,不可隨意混搭廠商元件,並且要透過工作台測試或模擬來驗證挑選的品項。

C0G MLCC 正在眾多應用中取代薄膜電容和 X7R MLCC,例如諧振電路就可在 OBC 和其他關鍵應用中提供高效且高效能的電源轉換。這些元件具有超穩定性與小型化的特點,再加上高電壓,因此是極具吸引力的設計選擇。

TDK 的高電容量 C0G MLCC

2025 年時,TDK Corporation 將其 CGA (汽車級) 系列和 C (商用和工業級) 系列的表面黏著 C0G MLCC 擴充到 10 nF,這對 1,250 V 額定值產品來說,是業界公認最高的電容量。此系列採用 3225 (3.2 x 2.5 x 2.5 mm) 封裝外殼。相比之下,TDK 的高壓 X7R 元件則更大,且僅支援最高 630 V。

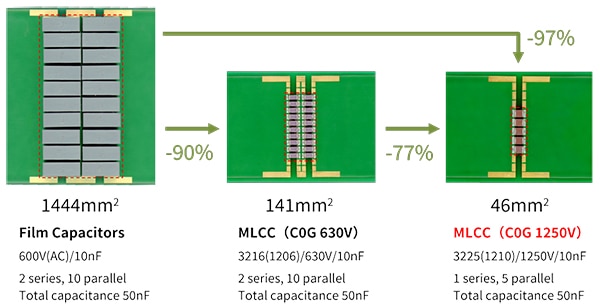

C3225 和 CGA6P C0G 產品線採用最佳化的產品和工藝設計,可提供高壓阻抗。一樣採用 3225 外形尺寸,因此設計人員可以利用此產品線來縮小實體尺寸並減少串聯安裝的 MLCC 數量 (圖 2)。

圖 2:針對使用薄膜電容、較低電壓 MLCC 和更高電壓 MLCC 的類似電容組,其所需的安裝面積比較。(圖片來源:TDK Corporation)

圖 2:針對使用薄膜電容、較低電壓 MLCC 和更高電壓 MLCC 的類似電容組,其所需的安裝面積比較。(圖片來源:TDK Corporation)

與其他產品相比,TDK 的 C0G MLCC 經過最佳化,可減少發熱,進而延長使用壽命並提高可靠性。非常適合汽車和商業應用中的諧振和緩衝電路、DC/DC 轉換器以及無線充電應用。

TDK 元件的緊湊尺寸能讓設計人員針對新一代車輛提供更小、更高效且符合 AEC-2000 標準的應用。可在 -55°C 至 125°C 的溫度範圍內,以及嚴峻條件下,包括熱衝擊、振動和溫度循環,確保達到可靠的效能。

CGA6P1C0G3B103G250AC 汽車級 MLCC 提供 10 nF 的電容量和 ±2% 的容差。C0G 介電質可在溫度範圍內達到優異的穩定性,並可耐受引擎箱的劇烈溫度與振動。在高壓諧振和緩衝電路中特別有用,例如電動車充電系統和電力電子設備中的電路。CGA6P1C0G3B103J250AC 可提供相同的電容量,但容差為 ±5%。

C3225 元件採用相同的封裝和溫度範圍特性,但成本更低,專為更溫和、規範較少的商業和工業環境而設計。如同 CGA6 系列中的對應產品,C3225C0G3B103G250AC 亦採用相同的 3225 封裝,可提供 10 nF 電容量和 1,250 V 的高額定電壓,電容量容差為 ±2%,因此適用於精密應用。C3225C0G3B103J250AC 具有 10 nF 的電容量和 ±5% 的容差。

結論

設計人員可以放心使用 C0G MLCC 取代較大的薄膜或電解電容、簡化電路板佈局,並增進新一代電源和汽車系統的系統可靠性。TDK 的商用級 C3225 和汽車級 CGA6P C0G MLCC 能針對高電壓、高可靠性應用提供極具吸引力的選擇,以緊湊的封裝提供業界領先的電容量,並可達到優異的穩定性。

聲明:各作者及/或論壇參與者於本網站所發表之意見、理念和觀點,概不反映 DigiKey 的意見、理念和觀點,亦非 DigiKey 的正式原則。