Autonomous Mobile Robot

The onsemi Autonomous Mobile Robot concept is a comprehensive robotics solution designed with highly efficient and innovative solutions from onsemi. The concept can be used to design various types of Robots, Cobots, Power tools and Autonomous Guided Vehicles by combining different intelligent and power solutions from onsemi.

- BLDC Motor Control Kits

- Battery Charging and Power Conversion

- Image Sensors and Lidar solutions

- Connectivity Solutions

- LED Lighting

- Industrial Cobots and Robots

- Warehouse Robots

- Delivery Robots

- Power Tools

- Agricultural Robots

- Lawn Mowers

- Autonomous Guided Vehicles

- BLDC Motor Control Solutions

- Sensing Solutions

- Power Solutions

- Lighting Solutions

- Communication Solutions

BLDC Motor Control Solutions

First we have the BLDC motor control solution and there we could actually choose three different platforms. The first one our ecospin based integrated motor development ship. This is a fully integrated solution for motor BLDC control. It has integrated bootstrapped diodes. As well as a sense amp and gate driver and a microcontroller. The firmware is available.

The second solution is Xilinx's based system that uses discrete gate drivers and MOSFETS. It can be used for platforms where more compute power at the motor control level is needed.

And lastly, we have a power tools based solution.

Featured Products

NCD83591MNTXG

View Details

NVMFS5C410NWFAFT1G

View Details

NCP730BMT250TBG

View Details

NCH-RSL15-512-101Q40-ACG

View DetailsSensing Solutions

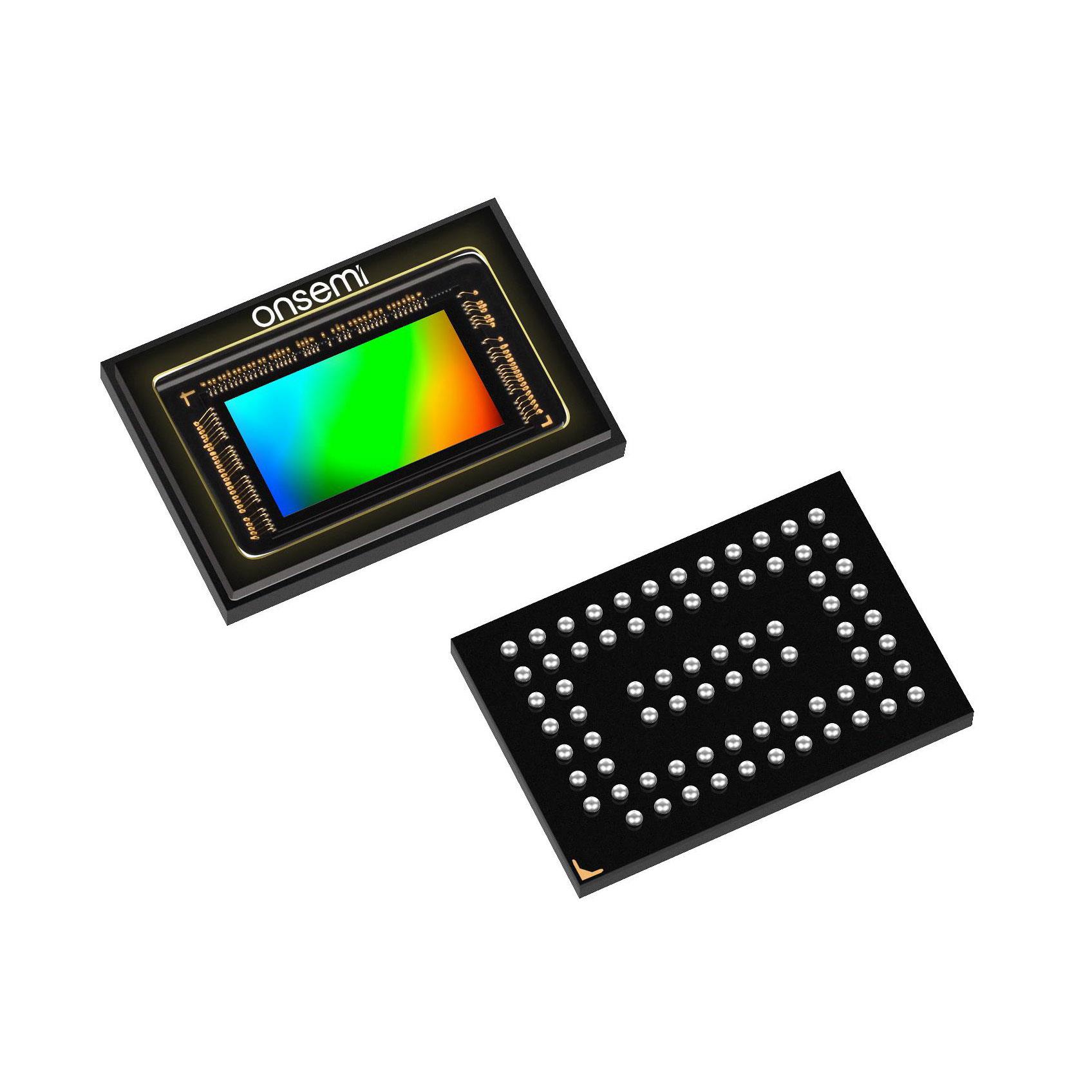

The autonomous robot needs to see where it is going: so it needs an image sensor and camera module. Our demonstration uses an E-con USB camera module. This uses a global shutter image sensor which is ideal for autonomous robots. Global shutter sensors store the pixel data in each image at the same time. These type of sensors do not have the motion artifacts seen in rolling shutter sensors, so they are ideal for use when moving around factory or warehouse floors. Rolling shutter sensors have a higher dynamic range than global shutter sensors so can work better where there are extreme differences in lighting conditions. However for autonomous robots working in factories the lighting conditions are suitable to allow the use of global shutter sensors. The AR0234CS image sensor supports full HD images at a frame rate of sixty frames per second.

Autonomous robots with movable arms use servo motors to control the position of the arms and grabbers. This requires accurate position feedback. Further, if the autonomous robot is powered off and then on again, it is important to know the exact position of the arm. An absolute position sensor can determine the position of the arm at any time. Optical sensors can do this but they need a lot of external components and they are sensitive to variations in temperature. Onsemi is an established supplier of high reliability custom position sensors for the automotive market. From this experience, we have developed a dual inductive position sensor solution which uses the NCS32100 sensor controller. I will go into more detail about this product a little later in this presentation.

Featured Products

AR0234CSSM00SUKA0-CR

View Details

AR1335CSSM11SMKA0-CP

View Details

AR0822NPSC10SMTA0-DR

View Details

NCS32100XMNTXG

View Details

NCV75215DB001R2G

View DetailsPower Solutions

Let’s now look at the power supply for the autonomous robot. For sure it is powered off a battery but the battery needs to be charged at some point. The autonomous robot has the intelligence to drive to the power charging point. An external robot arm connects the power cable to the autonomous robot to charge up the robot.

The 600W AC mains input battery charger for the autonomous robot consists of three sections: a PFC stage, an isolated LLC converter and a buck converter. The PFC stage is a dual interleaved PFC stage using the NCP1632 PFC controller. This ensures that the power drawn from the AC line has good power factor and low total harmonic distortion. The LLC stage converts the output of the PFC stage, which is something like 400VDC, to a 48V DC output voltage using a LLC topology with a center-tapped half bridge topology. The NCP1399 is used in the current design, with the more advanced NCP13994 recommended for newer designs. The output is synchronously rectified using two FDMS86202ET medium voltage MOSFETs controlled by two NCP4305D synchronous rectification controllers.

Battery charging profiles include constant current charging modes which result in a wide range of operating voltages. LLC stages have a narrow operating range for their voltage conversion ratio, or gain, so they do not work well in constant current mode. In the autonomous robot charger, there is a third buck stage using the FAN65008 which can runs with a very wide range of voltage conversion ratios so can easily provide the current and voltage profiles required for battery charging.

Featured Products

NCP1681ABD2R2G

View Details

NCP51530BMNTWG

View Details

NCP51561BADWR2G

View Details

NTHL045N065SC1

View Details

NCP13994AADR2G

View Details

NCP51561BADWR2G

View Details

NTHL045N065SC1

View Details

NCP4318ALSDR2G

View Details

NCP1076STAT3G

View Details

FAN65008B

View Details

FODM1008

View Details

FDMS86202ET120

View Details

RSL15

View DetailsLighting Solutions

Our autonomous robot solution is equipped with LED lights to show its presence to people and other robots. Additional LED lights are used for signaling. Onsemi is an established supplier of headlight, tail light, daytime running light and signal light solutions to the automotive and industrial vehicle market. We selected two products from this wide portfolio to use in our autonomous robot.

The NCV7685 automotive tail LED light solution is a driver + integrated MOSFET solution which is simple to use. There are 12 parallel 60mA channels which are PWM controlled via an I2C interface. If the designer wants to operate the LED driver without an external microcontroller, they can pre-program specific OTP registers to set the duty cycle. The LED driver has fault diagnostics which can be read back by the microcontroller to detect specific errors such as short circuit conditions on the pin setting the current, an error in the I2C communication, thermal warning, thermal shutdown and open load conditions. This information can be used by the microcontroller to support necessary corrective actions such as communicating the error back to a central host controller which is monitoring the local autonomous robots.

Featured Products

NCV7685DQR2G

View DetailsCommunication Solutions

Traditionally, robotics suppliers selected the automotive CAN protocol for wired communication between different nodes within the robot, including BLDC, lighting, processor, and some sensors. CAN has been around for decades using lightweight and inexpensive unshielded twisted pair (UTP) wiring in a multidrop or daisy chain topology, facilitating 2 mbps to 5 mbps communication between nodes. Meanwhile, as robots take on more autonomy, or work in closer harmony with humans, robotic intelligence needs to be augmented. Robotic intelligence is enhanced by adding more processing and sensors to the robot, including Lidar, image sensors, ultrasonic, radar, and inductive positioning. Image sensors and Lidar are driving more point to point (p2p) communication links to the processor node requiring faster data rates like Gigabit Ethernet. One drawback with CAN is you need a gateway between the Ethernet and CAN, because the protocols are different.

In 2019 the Ethernet Alliance ratified the IEEE802.3cg standard for 10BASE-T1S, as an “All-Ethernet” CAN replacement. Now with 10BASE-T1S, you can communicate 2x to 3x faster than CAN on the same two wires (SPE: Single Pair Ethernet) and relinquish the added gateway cost and weight using onsemi’s NCN26010 or NCN26000 controllers.

Featured Products

NCN26010

View Details

NCN26000

View Details

NCV7340

View Details

NCV7342

View Details

NCV7343

View Details

NCV7344

View Details

NCV7349

View Details

NCV7351

View Details

NCV7356

View Details

NCV7357

View Details

NCV7390

View Details

NCV7446

View Details

NCV7450

View Details