Ultra-Rugged Connectors Show How Far the Technology Has Come

A recent home address change saw the removal workers detaching HDMI connectors from the back of my set-top box (STB). Not realizing that the connectors had screws holding them in place, the moving “experts” pulled and pulled until the cables and connectors finally gave way. I’m not sure which was most remarkable: the fact that, despite my protests, they kept heaving on something that was clearly not meant to budge or how much punishment the connector could take before finally giving up the ghost.

While wireless technology plays a crucial role in modern society, it’s still very much a wired world. Wireless bandwidth continues to increase but, in most cases, can’t approach that of a metal conductor. And though they have improved dramatically over the years, wireless connections can sometimes prove tricky to set up and temperamental in operation. In contrast, wires are robust, simple to install, and ultra-reliable.

And where there’s a wire, there’s a connector: a component without the glamour of a wireless chip, microcontroller, or high-speed memory device, built using advanced manufacturing techniques and materials, yet playing just as critical a role and needing to be competitively priced. Connectors are the unsung heroes keeping modern electronic devices humming along.

Connectors grow in importance

Once my annoyance with the ham-fisted removal experts subsided, I considered how connectors have quietly and inexorably evolved over the years. Connectors were relatively unsophisticated devices in my formative years as a design engineer. RS232 was considered leading-edge, USB downright exotic, and HDMI wasn’t even a twinkle in a connector designer’s eye. The USB-A connector, like the USBR-A-S-F-O-VU from Samtec, has stood the test of time (Figure 1).

Figure 1: The venerable USB-A connector, such as the USBR-A-S-F-O-VU, is a relatively simple device that has served well for nearly 30 years. (Image source: Samtec)

Figure 1: The venerable USB-A connector, such as the USBR-A-S-F-O-VU, is a relatively simple device that has served well for nearly 30 years. (Image source: Samtec)

Connectors were typically one of the last components to be selected for a design, almost as an afterthought and rarely with extended investigation of the options. And yet, when equipment went wrong, we blamed the connectors first. Unmating and mating the cable sometimes fixed an errant oscilloscope, but faulty crimping and broken pins were so endemic that, typically, the connector failed completely. But at least it could be cracked open and a globule of solder applied for satisfactory repair.

Not so today. Contemporary HDMI and other high-speed connectors must keep pace with rapidly evolving communications standards by offering more pins, finer pitches, higher signal integrity, and greater bandwidth with each iteration. While consumer repair is hardly an option, thankfully, it’s not needed because quality standards ensure even the most straightforward connector survives the most challenging operating conditions and repeated mating and unmating for years without missing a beat.

Connectors exhibit advanced technology

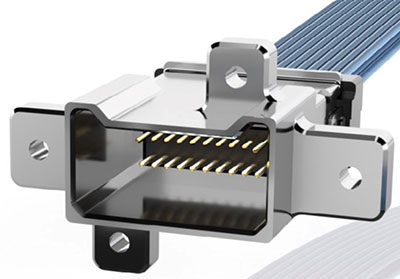

Some recently introduced products from Samtec are good examples of how far connector technology has come. As the name suggests, the URSA I/O Ultra Rugged Cable System targets high reliability and high mating cycle ultra-rugged applications. The B1SDT-10-28-H-10.0-1, for instance, is a cable-mounted, 20-position rectangular socket-to-socket connector. The connector features beryllium-copper contacts with gold plating and is rated at 3.8 amperes (A) per pin at 253 volts AC (VAC) (Figure 2).

Figure 2: The B1SDT-10-28-H-10.0-1 from Samtec is a rectangular socket-to-socket connector targeting ultra-rugged applications. (Image source: Samtec)

Figure 2: The B1SDT-10-28-H-10.0-1 from Samtec is a rectangular socket-to-socket connector targeting ultra-rugged applications. (Image source: Samtec)

The heart of the connector system is the CC508-01-H-M URSA I/O crimp contact (Figure 3). This features a hyperboloid contact that provides four points of connection to ensure low and stable electrical resistance, reduced insertion and extraction forces, consistent performance under vibration and shock, and a high number of mating cycles.

Figure 3: Samtec’s hyperboloid contact provides four connection points and ensures low and stable electrical resistance. (Image source: Samtec)

Figure 3: Samtec’s hyperboloid contact provides four connection points and ensures low and stable electrical resistance. (Image source: Samtec)

The cable-to-cable and cable-to-board solutions in the URSA family offer reliable connection in a small form factor, which allows for high-density connectivity. Electromagnetic interference (EMI) shielding helps to limit signal degradation for robust performance. Designed for a wide range of applications, including 5G networking, industrial, medical, and broadcast, the connectors feature a 1.00 millimeter (mm) pitch in a double-row, space-saving design. They are even robust enough for space flight.

The P1PDT-10-28-H-10.0-B1 is the panel mount version of the connector. This type allows for high-density connectivity with up to 1,450 total I/Os in a 1RU panel (29 cables x 50 I/Os) (Figure 4).

Figure 4: The URSA panel mount socket allows for high-density connectivity with up to 1,450 total I/Os in a 1RU panel. (Image source: Samtec)

Figure 4: The URSA panel mount socket allows for high-density connectivity with up to 1,450 total I/Os in a 1RU panel. (Image source: Samtec)

Conclusion

The days when the connector was the Achilles’ heel in a signal path are long gone. Today’s connectors from manufacturers such as Samtec feature advanced material and electromechanical technology to ensure robust performance, reliability, and signal integrity in the most challenging conditions, even in the harsh environment of space. This assumes, of course, that the user has a smidgen of mechanical empathy. Everything has its limits.

Have questions or comments? Continue the conversation on TechForum, DigiKey's online community and technical resource.

Visit TechForum