Three Fantastic Electronic Design Tips to Better the Environment

How electronic engineers go green now and in the future.

The world is hooked on electronics. According to Statista, 2023 saw a total of 6.7 billion smartphone subscriptions worldwide. In a similar 2023 study, the outlet found that Americans replace consumer and enterprise smartphones every 2.67 and 2.54 years, respectively. That’s a lot of e-waste, but it reflects only a fraction of the total. For that value, Statista estimates that 2022 saw a global total of 62 million metric tons.

Unfortunately, humans have yet to find an environmentally friendly and economical way to process e-waste. This is concerning as its improper processing and disposal can release a handful of toxic substances into our environment, including lead, mercury, arsenic, and more. It should also be noted that the manufacturing of electronics can be just as detrimental.

All of these factors have created a demand for green and sustainable electronic products. And though the currently available options are limited, here are some things electronic design engineers should keep in mind to make greener choices.

Three environmental concepts to design electronics

There are a number of concepts electronic engineers can use to improve their designs from an environmental perspective. These are:

- Sustainable design

- Green manufacturing

- Circular economy

According to McKinsey & Company, “Our analysis suggests that while R&D accounts for 5 percent or less of the total cost of a product, it influences up to 80 percent of that product’s resource footprint.”

As a result, sustainable design might be the most important factor when developing new electronics. The process involves adding environmental considerations into the design of a product’s whole lifecycle — from the collection of raw materials to the product’s inevitable disposal. This has become easier to implement as many CAD, PLM, and engineering design tools have embedded environmental lifecycle assessments (LCAs) into their core technology.

Second, it’s no secret that electronic manufacturing processes carry a significant environmental impact. Though more sustainable processes are being researched, engineers can still make a difference here. By implementing smart manufacturing methodologies, they can improve a factory’s energy efficiency and reduce its waste streams. Additionally, by choosing renewable energy sources to power production, engineers can take the first step to making these processes greener.

Finally, engineers need to start designing products with a circular economy in mind. This means that a product, its parts, and even its raw materials are easily reused, repaired, or recycled. This goes beyond a right to repair and resell electronic goods. Corporations need to come up with recycling workflows that can easily refurbish or repurpose old products into new ones.

The environmental electronics available now and in our future

This all begs the question, what eco-friendly parts and materials are available to engineers? Unfortunately, for the electronics industry, options are currently limited.

Many researchers are assessing the possibility of producing electronic components from recycled and abundant materials. Others, however, are going a more synthetic organic materials route. Examples include:

- Silk- or paper-based materials for green electronics and photonics

- Ion-conducting hydrogels for bioelectronics

- Conductive polymer composites that are biocompatible and biodegradable

- Bio-pigments and graphitic carbon quantum dots for electrochemical energy storage

- Green solvents for slot-die-coated organic UV indicators and filters

- Organic LED substrates based on bacterial cellulose and recycled polystyrene

However, some of the most promising research is in organic field-effect transistors (OFETs). The goal is for OFETs to replace traditional electronic components such as substrates, semiconductors, and dielectrics. These would be bio-degradable and made from abundant materials. Some concept products that have been produced include foldable displays, ID cards, sensors, and even artificial skins. However, the development and research of OFETs is still in the early stages.

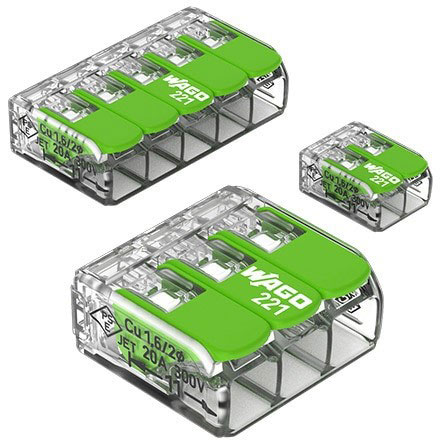

So, what green parts are currently available to engineers? One example is WAGO’s Green Range 221 series of splicing connectors. The connectors are partly made of bio-circular material and recycled plastics.

WAGO’s Green Range 221 series of splicing connectors are partly made from bio-circular material and recycled plastics. (Image source: WAGO)

WAGO’s Green Range 221 series of splicing connectors are partly made from bio-circular material and recycled plastics. (Image source: WAGO)

In addition, Allegro Microsystems offers a line of power and sensing solutions that streamline designs and optimize energy transfers. These products are also designed for green applications such as solar inverters, heat pumps, and electric vehicle (EV) chargers.

As for other parts that are optimized for green applications, engineers can look to ITT Cannon for a series of customizable EV charging interconnects. In addition, Klein Tools offers a 60 W foldable solar panel that can quickly charge power banks, power stations, and portable batteries.

Finally, IEEE Spectrum reported that there is a “gallium nitride (GAN) and silicon carbide (SiC) fight for green tech domination.” The outlet added that “regardless of which one wins, they will cut greenhouse gases by billions of tonnes.” This is mostly due to the fact that GaN and SiC perform more efficiently than traditional silicon components. This has already led to the material cutting the lighting industry’s electricity use by 30 to 40 percent. As a result, these materials are now starting to transition to other electronic applications.

For more information on GaN and SiC and the environmental advantages they have over traditional silicon transistors, watch the webinar: Which Wide Bandgap Technology is Best Suited for Your High Efficiency Application?

Have questions or comments? Continue the conversation on TechForum, DigiKey's online community and technical resource.

Visit TechForum