Simplify Cable Termination with Push-X Terminal Block Technology

I’ve terminated enough cables over the years to get frustrated with various connector technologies. From fussy tools to awkward cable routing, I’ve often hoped for a better solution.

As it turns out, I’m not alone. Phoenix Contact recently introduced their Push-X terminal blocks to address these issues. Unlike previous push-in terminal blocks, the Push-X series can accommodate flexible conductors, including stranded styles, without the need for ferrules. As a result, a wire stripper is the only tool installers need.

How does Push-X work?

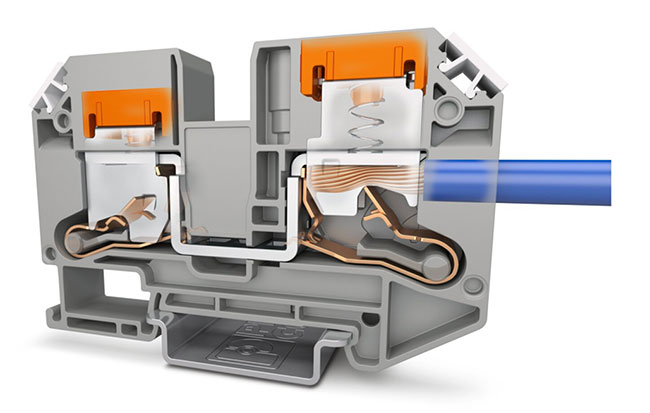

The secret to Push-X technology is a pre-tensioned contact spring (Figure 1). A conductor only needs to lightly push down on the release surface of the copper contact spring and the mechanism will snap closed, electrically and mechanically securing the inserted conductor to the alloy current bar.

Figure 1: Shown in the closed position, a terminal block with Push-X technology features a contact spring that is triggered by a conductor pushing down on its release surface. (Image source: Phoenix Contact)

Figure 1: Shown in the closed position, a terminal block with Push-X technology features a contact spring that is triggered by a conductor pushing down on its release surface. (Image source: Phoenix Contact)

Push-X technology stands out not only for its ease of use but also for its flexibility. The terminal blocks can be used with a wide range of conductors across various applications, including power and signaling applications in transportation, utilities, data centers, and industrial automation.

Accidental engagement is hard, intentional reset is easy.

Can accidental engagement occur with a spring that is easily triggered? In short, the answer is no. The spring is designed so that bumping or shaking the terminal block is unlikely to engage the mechanism. Phoenix Contact puts Push-X terminal blocks through a battery of tests to ensure this is the case, including a simulation of conditions encountered during shipping and a scenario where the terminal blocks are dropped multiple times during installation.

If a conductor needs to be removed, opening the contact is as easy as closing it. The terminal block features an orange pusher with an “X” imprint that pops up when the contact spring is engaged. To remove the wire, the user simply has to depress the pusher. This also reloads the contact spring for a new wire (Figure 2).

Figure 2: In its factory setting, the pusher is depressed, as shown on the left. The orange pusher pops up when the contact spring engages a conductor, as shown on the right. (Image source: Phoenix Contact)

Figure 2: In its factory setting, the pusher is depressed, as shown on the left. The orange pusher pops up when the contact spring engages a conductor, as shown on the right. (Image source: Phoenix Contact)

The XTV series are the first terminal blocks to integrate Push-X technology. They are available in cross-sections of 6, 10, and 16 square millimeters (mm2), making them suitable for flexible wires with cross-sections between 1.5 and 25 mm2. This is between 14 and 4 American Wire Gauge (AWG). For rigid wires, cross-sections as small as 0.5 mm2 (20 AWG) are supported. The support for such small conductors is remarkable and demonstrates the minimal force required to trigger the contact spring.

Thoughtful design details

Several other features make these terminal blocks easy to work with. For example, the product line includes feed-through terminal blocks (1329672) to connect two wires, as well as multi-conductor terminal blocks to connect three (1329506) or four wires (1329511) to a single current bar. These multi-conductor configuration options reduce the number of blocks and lines needed, simplifying wire routing and saving space (Figure 3).

Figure 3: Push-X terminal blocks come in three sizes to accommodate a wide range of conductor sizes and are available in 2, 3, and 4-conductor variants. (Image source: Phoenix Contact)

Figure 3: Push-X terminal blocks come in three sizes to accommodate a wide range of conductor sizes and are available in 2, 3, and 4-conductor variants. (Image source: Phoenix Contact)

In addition to the gray blocks shown in Figure 3, the series offers a range of color variations. Notably, there are green-yellow (1329550) protective conductor terminal blocks designed to align with the color of protective earth cables, making it easier for installers to identify the correct terminal block.

Another ease-of-use feature is the QR code in the product labeling, which gives users immediate access to the information and support they need.

Industry-standard performance

Along with unique design features, the Push-X series offers the standard performance characteristics expected in a terminal block system.

It supports currents of up to 76 amperes (A) at 1000 volts according to International Electrotechnical Commission (IEC) standards, or 75 A at 1000 volts using Underwriters Laboratories (UL) standards. The series is compatible with Phoenix Contact’s DIN rail terminal blocks, meaning it can use the company’s wide selection of accessories like bridges and switching jumpers.

Conclusion

Although it’s been years since my job involved terminating cables, I can still appreciate what Push-X offers. I would have loved to have needed nothing more than a cable stripper and a light insertion force to secure my wiring. By simplifying the task of cable termination, Push-X improves efficiency, reduces errors, and simplifies maintenance.

Have questions or comments? Continue the conversation on TechForum, DigiKey's online community and technical resource.

Visit TechForum