How to Quickly and Cost-Effectively Add Industrial Ethernet to Industry 4.0 Equipment

Designers of smart factories for Industry 4.0 and the Industrial Internet of Things (IIoT) need to be able to quickly deploy compact, robust, low-latency, and low-power automation and control network interfaces. The performance requirements are being increasingly satisfied by industrial Ethernet (IE), which uses protocols like PROFINET, EtherNet/IP or EtherCAT encapsulated within the Ethernet protocol, and a modified media access control (MAC) layer to provide the low-latency and real-time performance demanded for Industry 4.0 equipment.

However, it can be challenging to gather all the required components for a flexible IE implementation while also ensuring the IE software is certified to ensure reliable operation and interoperability.

There are also power efficiency and environmental challenges. For example, IE networks generally use line or ring network structures that have reduced wiring length compared to star networks. However, line and ring networks require two Ethernet ports for each device, making the physical layer (PHY) power dissipation a key design consideration.

The elevated temperatures found in industrial environments, combined with the need for compact solutions, make it critical that designers carefully manage the power dissipation budget for IE implementations.

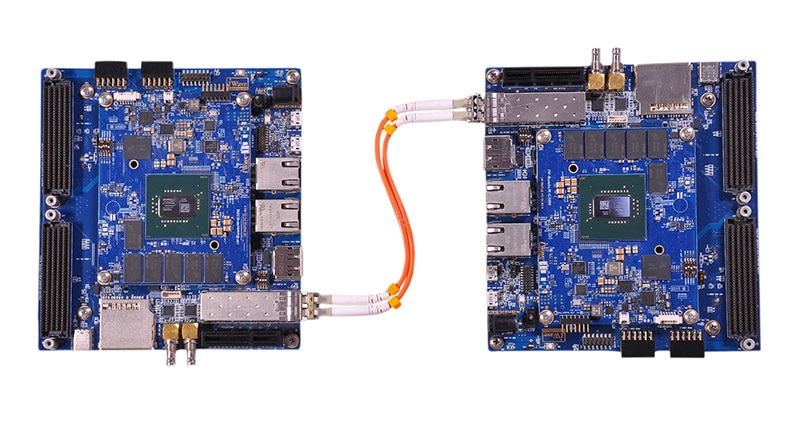

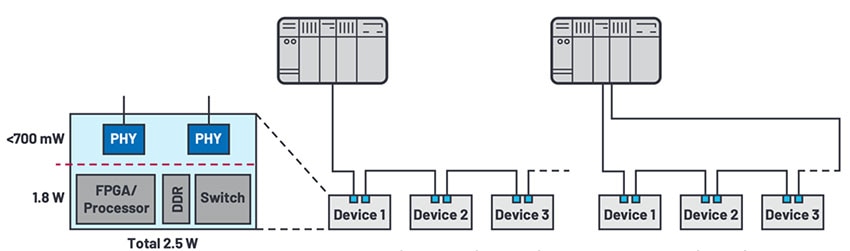

Consider an IE port with a 2.5 watt power dissipation budget where the field programmable gate array (FPGA), double data rate (DDR) memory, and Ethernet switch consume 1.8 watts. That leaves 700 milliwatts (mW) available for two PHYs (Figure 1).

Figure 1: Each device in an Ethernet line (center) or ring (right) architecture requires two PHYs (left). (Image source: Analog Devices)

Figure 1: Each device in an Ethernet line (center) or ring (right) architecture requires two PHYs (left). (Image source: Analog Devices)

In addition to meeting challenging power dissipation budgets, industrial equipment needs to meet several electromagnetic compatibility/electrostatic discharge (EMC/ESD) International Electrotechnical Commission (IEC) and European Norm (EN) standards:

- IEC 61000-4-2 ESD

- IEC 61000-4-4 electrical fast transient (EFT)

- IEC 61000-4-5 surge

- IEC 61000-4-6 conducted immunity

- EN 55032 radiated and conducted emissions

Testing to all these standards is costly and time-consuming. And, if anything goes wrong during testing and certification, it extends time-to-market and increases costs.

Reference design simplifies IE implementation

To help address the numerous challenges related to implementing IE, Analog Devices developed the Chronous RapID Platform Generation 2 embedded reference design. Chronous provides a complete development environment for IE that includes verified and proven hardware and software for popular IE protocols.

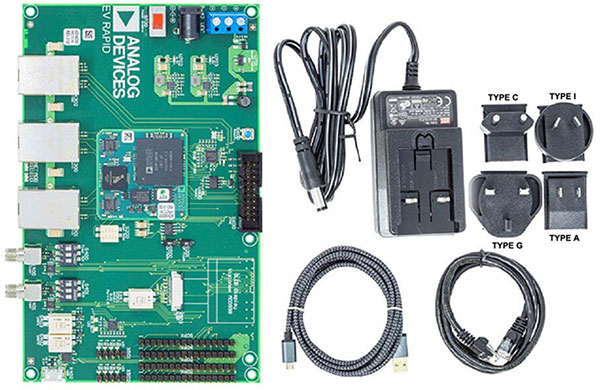

It includes two Ethernet PHYs, making it suitable for use in devices networked with line or ring topologies. Three boards are available that include pre-certified software for EtherCAT (EV-RPG2-ECZ), EtherNet/IP (EV-RPG2-ENZ), and PROFINET (EV-RPG2-PNZ). The EV-RPG2 evaluation kits (Figure 2) provide a complete development environment including:

- Baseboard with the ADIN2299 RapID Generation 2 module with certified protocol software

- Wall-mount alternating current (AC) adapter with universal plug adapters

- USB A male to USB micro B male cable

- Ethernet cable

Figure 2: EV-RPG2 evaluation kits include everything needed to rapidly deploy IE networked devices. (Image source: Analog Devices)

Figure 2: EV-RPG2 evaluation kits include everything needed to rapidly deploy IE networked devices. (Image source: Analog Devices)

The EV-RPG2 dev kits enable designers to quickly verify the communication path between a host processor and a smart factory device, such as a programmable logic controller (PLC), prior to integration. Along with the pre-tested software, the EV-RPG2 features low power consumption, has been tested to the relevant IEC and EN standards, and supports customization for a variety of use cases.

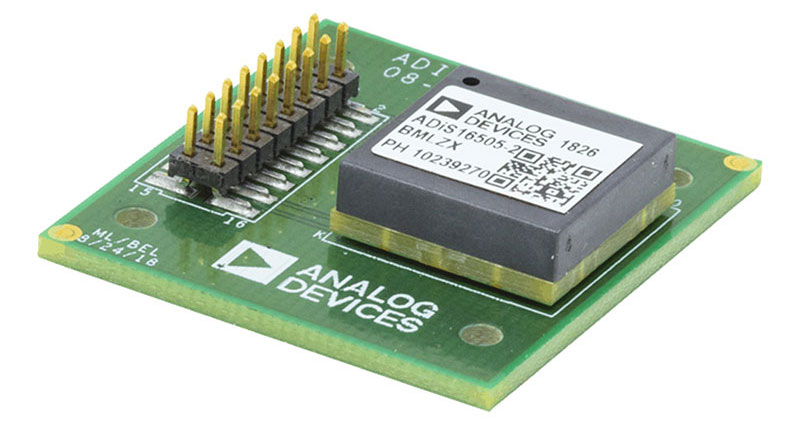

The ADIN2299 module features a small form factor for embedded applications, as well as low power consumption and low latency. It’s a complete, pre-tested solution that manages the industrial protocol and network traffic for an applications processor, and speeds the integration of IE into field devices. It includes a communications controller, protocol stack, flash memory, RAM, follower controller, and two PHY interfaces, as well as the specific software needed for EtherCAT, PROFINET real-time (RT) or isochronous real-time (IRT), and EtherNet/IP networking (Figure 3).

Figure 3: The ADIN2299 module features a small form factor for embedded applications and has two Ethernet PHYs (right). (Image source: Analog Devices)

Figure 3: The ADIN2299 module features a small form factor for embedded applications and has two Ethernet PHYs (right). (Image source: Analog Devices)

The PHY in the ADIN2299 embedded IE module uses two ADIN1200, low power, single-port 10 megabit per second (Mbit/s) and 100 Mbit/s Ethernet transceivers. The ADIN1200 has an energy-efficient Ethernet PHY core, analog circuitry, input and output clock buffering, management interface and subsystem registers, MAC interface, and control logic. Additional features of the ADIN1200 include:

- 10BASE-Te/100BASE-TX IEEE 802.3 compliant

- Media independent interface (MII), reduced MMI (RMII) and reduced gigabit MMI (RGMII) MAC interfaces

- 100BASE-TX RGMII latency: transmit <124 nanoseconds (ns), receive <250 ns

- 100BASE-TX MII latency: transmit <52 ns, receive <248 ns

- Meets –

- IEC 61000-4-4 electrical fast transient (EFT) (±4 kilovolts (kV))

- IEC 61000-4-5 surge (±4 kV)

- IEC 61000-4-6 conducted immunity

- EN55032 radiated and conducted emissions (Class A)

- −40 to +105 °C ambient operating range

- Power consumption of 139 mW for 100BASE-TX at 1.8 volts

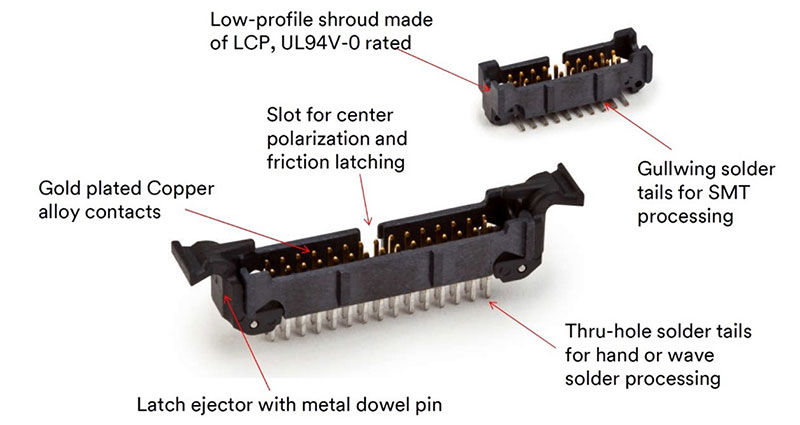

- 5 × 5 millimeter (mm), 32-lead lead frame chip scale package (LFCSP) (Figure 4)

Figure 4: ADIN1200 Ethernet transceivers are robust, and their 5 mm2 LFCSP package supports compact solutions. (Image source: Analog Devices)

Figure 4: ADIN1200 Ethernet transceivers are robust, and their 5 mm2 LFCSP package supports compact solutions. (Image source: Analog Devices)

Conclusion

IE protocols like PROFINET, EtherNet/IP, and EtherCAT can support the need for low-latency automation and control network interfaces required in Industry 4.0. To accelerate IE deployment and lower costs while ensuring interoperability, Analog Devices provides a reference design with efficient PHYs and a rich suite of pre-certified software.

Recommended Reading

Design for Rugged IoT Applications Using Industrial Ethernet-Based Power and Data Networks

Have questions or comments? Continue the conversation on TechForum, DigiKey's online community and technical resource.

Visit TechForum