Design for Rugged IoT Applications Using Industrial Ethernet-Based Power and Data Networks

Contributed By DigiKey's North American Editors

2022-08-24

Connecting manufacturing facilities to the Internet results in efficiency, quality, and productivity gains. For example, machines can be programmed and controlled remotely, data from machines and processes can be continuously analyzed to check for process errors or drift, and remote tweaks can be made to tune production in a closed feedback loop. Longer term, the data can be used to plan for future scaling and more rapid integration of new manufacturing techniques.

While the case is strong for connectivity, how that connectivity is accomplished requires serious consideration. There are many options, but Ethernet provides an accessible and proven solution for the factory network. It is the most widely used wired networking option, globally, with good vendor support and seamless interoperability with the cloud. Better yet, the cabling can be used to carry power (Power over Ethernet (PoE)) as well as data which means one set of wiring can both support the network and energize connected sensors, actuators, and other devices such as cameras.

However, standard Ethernet is not up to the industrial job. The hardware is not designed to reliably operate in the hot, dirty, and vibration-prone factory environment. Also, standard Ethernet protocols are non-deterministic and hence ill-suited to the needs of the factory environment where production requires near real-time control to manage high-speed processes.

Industrial Ethernet brings all the benefits of standard Ethernet but adds ruggedization and deterministic software to the mix. It is a proven and mature technology for industrial automation, not only allowing process data to be sent to the cloud, but also allowing a remote supervisor to easily access drives, PLCs, and I/O devices on the manufacturing floor. An amendment to the Ethernet standard, IEEE 802.3cg, uses just a single pair of wires for data transport, cutting the bulk and cost of factory cabling.

This article discusses the connectivity challenge for industrial applications before outlining the differences between Ethernet and Industrial Ethernet. The article then considers the use of PoE and single pair Ethernet (SPE) technologies before introducing real-world hardware from Amphenol, and how it can be implemented in an Industrial Ethernet network.

The challenges of Ethernet for industry

While Wi-Fi might be the most popular way consumers connect to the Internet, commercial premises typically use Ethernet wired local area network (LAN) technology to link computers and other equipment together.

In Ethernet’s infancy, computers on the network used a single bus to communicate. This type of network is the most straightforward configuration and is cheap and easy to set up. However, it is relatively inefficient because connected computers compete for bandwidth, resulting in congestion, lost packets, and a marked reduction in bandwidth.

Today’s office networks typically use star, tree, or mesh topologies in which switches control access to the network to limit congestion to maintain throughput. Ethernet traffic is controlled by the switches such that direct messages go between only the devices that need to communicate, instead of broadcasting it over the entire network (Figure 1).

Figure 1: Ethernet switches control access to the network to limit congestion and maintain throughput. (Image source: Amphenol)

Figure 1: Ethernet switches control access to the network to limit congestion and maintain throughput. (Image source: Amphenol)

Based on a continuously updated standard (IEEE 802.3), Ethernet is proven, secure, reliable, and offers throughput speeds up to hundreds of gigabytes (Gbytes). While not part of the standard, Ethernet typically uses TCP/IP (part of the Internet Protocol (IP) suite) for routing and transport, making for seamless connectivity with the Internet. It also enables networks to easily scale with cables, connectors, and switches that are available from hundreds of vendors.

Ethernet has evolved to combine power and communications over a single Ethernet CAT 3 or CAT 5 cable, enabling engineers to construct low-maintenance Ethernet and power networks quickly and inexpensively, relative to installations employing separate systems. The technology has been formalized under an Institute of Electrical and Electronics Engineers (IEEE) standard called PoE. The key advantages of the technology are its simplicity and the fact that power is available wherever there is a data socket. (See, “Introduction to Power over Ethernet”.)

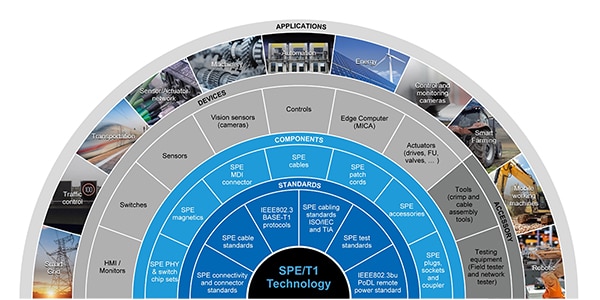

A recent amendment to the Ethernet specification, IEEE 802.3cg, describes the SPE alternative for carrying data over a single pair rather than the multistranded CAT 3 or CAT 5 cable of standard Ethernet or PoE. SPE is suited to industrial automation applications because it allows designers in the factory and building automation markets to use familiar Ethernet-based protocols for long-distance communication between industrial controllers and sensors, while significantly reducing the volume of wiring (Figure 2).

Figure 2: Single pair Ethernet is emerging as a space-saving and inexpensive form of Ethernet for a range of industrial and commercial applications. (Image source: Amphenol)

Figure 2: Single pair Ethernet is emerging as a space-saving and inexpensive form of Ethernet for a range of industrial and commercial applications. (Image source: Amphenol)

In principle, Ethernet represents an ideal way to link a supervisory front office to the manufacturing operation, effectively bridging the gap between information technology (IT) and operating technology (OT) networks.

Manufacturing facilities bring additional engineering challenges when implementing Ethernet. First, factories represent a hazardous environment for delicate cables, connectors, and switches. The environment is hot, dusty, and full of chemicals that are incompatible with the 100 meter (m) plus cable runs typical of factory implementations. Moreover, humidity and vibration play havoc with conductors and contacts. Additionally, factories are full of big motors that constantly switch on and off causing voltage transients and electromagnetic interference (EMI) that can disrupt Ethernet communications.

Second, a manufacturing facility is full of fast-moving robots and synchronized machines that need real-time control. Standard Ethernet’s non-deterministic communication mechanisms are ill-equipped to provide this control capability.

Industrial Ethernet hardware

“Industrial Ethernet” is the common term for Ethernet systems adapted for factory use. Such systems are characterized by rugged physical layers (PHY) and industrial protocols such as ModbusTCP, PROFINET, and Ethernet/IP. Moreover, unlike standard Ethernet implementations, Industrial Ethernet typically uses line or ring topologies because they help to shorten cable runs (limiting the impact of EMI), lower latency, and build in a degree of redundancy.

The cables are ruggedized and include shielding to protect against EMI, and connectors are similarly protected against the rigors of an industrial setting.

Manufacturers categorize the hardiness of their products according to the IP classification system. The IP rating indicates the degree of protection provided by the product and is defined by the international standard EN 60529. The scheme comprises two digits. The first represents the level of protection from solid objects, ranging from tools or fingers that could be hazardous if they encountered electrical conductors, to airborne dirt and dust that could damage circuitry. The second digit defines the protection from water drips, sprays, or submersion. The range extends from IP00 (no protection against dust or water) to IP69 (total protection against dust and powerful, high-temperature jets of water).

Industrial Ethernet connectors are typically encased in a range of protective housings up to IP67. In this case, a rating of six means no harmful dust or dirt will seep into the unit even after direct contact with the contamination for eight hours. A water protection rating of seven means the device can be submerged in up to one meter of fresh water for 30 minutes without damage.

When selecting PHYs, cables, and connectors for Industrial Ethernet, the designer should check immunity to EMI by scanning the datasheet for the following IEC and EN standards:

- IEC 61000-4-5 surge

- IEC 61000-4-4 electrical fast transient (EFT)

- IEC 61000-4-2 ESD

- IEC 61000-4-6 conducted immunity

- EN 55032 radiated emissions

- EN 55032 conducted emissions

Adherence to some or all of these standards provides reassurance that Industrial Ethernet system EMI performance in the factory environment will be satisfactory.

Ruggedized connectors

Whether they are built into machine control panels, Ethernet switches or cabling, connectors are vital to the performance of the Industrial Ethernet system. Without careful selection, a single connector failure while under the stress of high-speed production can cause million-dollar machines to malfunction or grind to a halt.

There are several vendors that offer proven and reliable Industrial Ethernet connectors for a range of Ethernet, PoE, and SPE applications. For example, Amphenol’s Industrial IP6X rectangular push-pull connector and cable solution provides CAT 6A Ethernet connectivity using the IEC 61076-3-124 mating interface, and full sealing to IP65, IP66, and IP67 specifications. Notably, the connectors are intended for use in Industrial Ethernet applications requiring additional environmental protection and are suitable for any indoor or outdoor rugged/harsh environment.

The family includes the panel mount NDHN200 IP67 rectangular connector housing shown in Figure 3. The NDHN3A2 10-position, multipurpose, solder-free plug connector (Figure 4), is designed to mate with the NDHN200. The plug connector includes a latch lock and shielded molding. It has a rating of 50 volts AC or 60 volts DC, 1.5 Amperes (A), and can be mated/unmated up to 250 times.

Figure 3: The NDHN200 is an IP67-rated rectangular connector housing for Industrial Ethernet applications. (Image source: Amphenol)

Figure 3: The NDHN200 is an IP67-rated rectangular connector housing for Industrial Ethernet applications. (Image source: Amphenol)

Figure 4: The NDHN3A2 is an IP67 plug connector that includes a latch lock and shielded molding. (Image source: Amphenol)

Figure 4: The NDHN3A2 is an IP67 plug connector that includes a latch lock and shielded molding. (Image source: Amphenol)

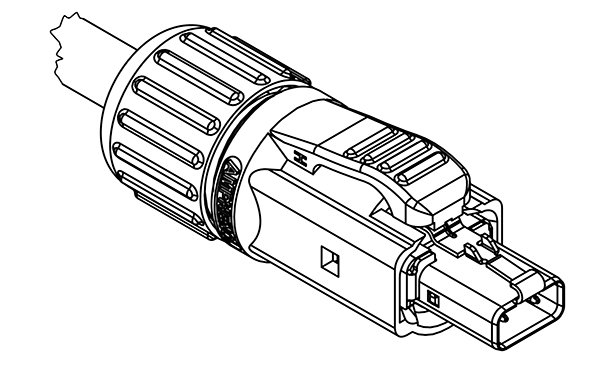

Amphenol has also released SPE connectors for Ethernet connectivity of peripheral devices like sensors, actuators, and cameras that operate at speeds up to one gigabit per second (Gbit/s). The SPE form factor reduces size, weight, and cost compared to standard Ethernet. The connectors are IP67-rated with an M12 size circular form factor. They mate to field-terminable plugs, providing a completely shielded interface with latching features. Their voltage/current handling capability of 60 volts DC and up to 4 A supports PoE over a distance of up to 1 kilometer (km). One example is the MSPEJ6P2B02, a 2P2C SPE connector (Figure 5)

Figure 5: The MSPEJ6P2B02 IP67 SPE connector comes in the popular M12 size circular form factor. (Image source: Amphenol)

Figure 5: The MSPEJ6P2B02 IP67 SPE connector comes in the popular M12 size circular form factor. (Image source: Amphenol)

The company also offers a similar range of SPE connectors with a rectangular plug format rated to IP20 rather than IP67. The solution offers the same electrical performance as the M12 range but is less expensive. An example is the MSPE-P2L0-2A0 modular SPE connector (Figure 6).

Figure 6: The MSPE-P2L0-2A0 modular SPE IP20 connector is a cost-effective option for less hazardous environments. (Image source: Amphenol)

Figure 6: The MSPE-P2L0-2A0 modular SPE IP20 connector is a cost-effective option for less hazardous environments. (Image source: Amphenol)

Industrial Ethernet protocols

Standard Ethernet’s communication mechanism is satisfactory for the relatively sedate traffic of an office or small business. But that mechanism is susceptible to disruption and lost packets, resulting in the increased latency that makes it unsuitable for the near real-time demands of a fast-moving and synchronized production line. As mentioned, such an environment requires a deterministic protocol to ensure machine instructions arrive on time, every time, no matter how high the loading on the network.

To overcome this challenge, Industrial Ethernet hardware is complemented by similarly “industrial” software. There are several proven Industrial Ethernet protocols available, including Ethernet/IP, ModbusTCP, and PROFINET. Each is designed to ensure determinism for industrial automation applications.

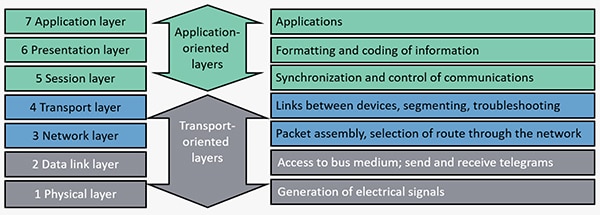

The difference between Ethernet and Industrial Ethernet software can best be described by considering the ISO/OSI seven-layer abstraction model (‘stack’), which comprises PHY, data link, network, transport, session, presentation, and application layers. Standard Ethernet comprises the PHY, data link, network, and transport layers (which use either TCP/IP or UDP/IP as the transport), and can be considered as a communication mechanism that brings efficiency, speed, and versatility.

In contrast, the Industrial Ethernet protocols, for example, PROFINET, use the application layer of the Industrial Ethernet stack. PROFINET is a communication protocol designed to exchange information between machines and controllers in an automation setting, using standard Ethernet as its communication mechanism (Figure 7).

Figure 7: The ISO/OSI seven-layer abstraction model representing the Industrial Ethernet software stack. Industrial Ethernet protocols such as PROFINET sit in the application layer. (Image source: Profinet)

Figure 7: The ISO/OSI seven-layer abstraction model representing the Industrial Ethernet software stack. Industrial Ethernet protocols such as PROFINET sit in the application layer. (Image source: Profinet)

Industrial Ethernet software can also leverage other protocols that are designed specifically for sending data to the cloud. Examples include protocols such as MQTT or SNMP.

Conclusion

To account for the factory’s harsh environment and real-time requirements, Industrial Ethernet uses ruggedized hardware such as switches, cables, and connectors, as well as Industrial software, to reliably connect the factory’s IT and OT networks.

As shown, proven commercial connector solutions make it simple for engineers to take advantage of Industrial Ethernet to program and control high-speed industrial automation, while gathering the deep data needed to enhance and scale manufacturing operations.

Disclaimer: The opinions, beliefs, and viewpoints expressed by the various authors and/or forum participants on this website do not necessarily reflect the opinions, beliefs, and viewpoints of DigiKey or official policies of DigiKey.