Four Critical, Low-Cost Tools to Make Hand Soldering Better and Easier

Solder is the conductive “glue” that binds almost everything together in the world of electronics, but did you know soldering predates electronics by several thousand years? There is evidence that artisans working in Mesopotamia as early as 5000 years ago used solder.

Evidence of soldering and brazing to produce jewelry, tools, and weapons appears very early in the history of metal working, perhaps as far back as 4000 BC. Today, in addition to making jewelry, tools, weapons, and assembling stained glass windows, we use solder to join copper water pipes.

In the world of electronics, soldering’s most critical role is to form a physical and conductive connection between wires, connectors, boards, and electronic components. While wave and reflow soldering may have become sciences based on strict time and temperature profiles, hand soldering remains very much an art that requires skill, understanding, dexterity, and the proper tools.

The first tool, the tool that everyone must have for soldering, is a good soldering iron. When it comes to soldering irons, the definition of “good” has evolved over time. My first soldering irons were cheap—what today would be called “wood burners” because they resembled the heating tools supplied with wood burning craft sets. Wood burners have no temperature control so they’re not especially good for electronics work, and especially not for today’s solders.

Figure 1: A good soldering station like the American Hakko FX888D allows you to set the soldering temperature needed for the task at hand. (Image source: American Hakko)

Figure 1: A good soldering station like the American Hakko FX888D allows you to set the soldering temperature needed for the task at hand. (Image source: American Hakko)

My first good soldering iron was a Weller WTCP soldering station, bought when I was in college. Temperature control was set by the soldering iron’s tips using magnetic Curie point technology, with your choice of 600°F, 700°F, or 800°F soldering temperatures. If you wanted to change operating temperatures, you turned off the iron, let it cool, and then swapped out the tip. This wasn’t particularly handy and so I never changed the soldering temperature.

As a testament to buying quality tools, especially when it comes to soldering, I’m still using this Weller soldering station half a century later. It has been a workhorse for me, and it’s still on my bench, but this model hasn’t been sold for decades. Tips for these irons are still available, though, suggesting that this soldering tool has been a workhorse for many, many people.

However, electronics has evolved a lot in the intervening decades, and the 60/40 tin/lead solder so prevalent 50 years ago, has been supplanted with many new types of solder (especially ecologically responsible, lead-free solders) that require many different soldering temperatures for optimum results. In addition, electronic components, connectors, wires, and pc board traces have all gotten smaller, so you need a large variety of soldering tips to accommodate all of the different soldering requirements you might face. That’s why I eventually purchased a more modern soldering station with an electronically variable temperature setting and a large selection of tips. I now have an earlier, non-digital version of today’s American Hakko FX888D soldering station (Figure 1).

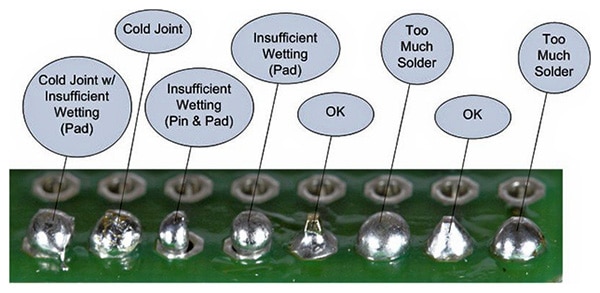

You need a good soldering station to handle all of the different types of soldering required to assemble and prototype modern electronic system designs. You’ll also need a good soldering station to avoid making all of the different types of bad solder connections illustrated in the rogue’s gallery (Figure 2).

Figure 2: A rogue’s gallery of bad solder connections illustrates the need for good soldering technique and good soldering tools. (Image source: Adafruit)

Figure 2: A rogue’s gallery of bad solder connections illustrates the need for good soldering technique and good soldering tools. (Image source: Adafruit)

This figure, taken from the Adafruit Guide To Excellent Soldering, illustrates many of the problems that occur when you haven’t mastered soldering and lack the right soldering tools. For example, you’ll get cold joints when the soldering iron is not hot enough or when you jostle the soldered joint while it’s cooling.

In addition to a good, temperature-controlled soldering station with a good selection of soldering tips, you’ll need needlenose pliers, wire cutters, flush cutters, and wire strippers. I’ve also found that there are many surprisingly inexpensive tools that clear the way to better soldering. Here are four of them that I can recommend.

Four inexpensive soldering aids

One of the most important of these soldering tools is a flux pen. Sure, there’s flux inside of most solders, and back in the day when component pins and wires were much larger, the diameter of the solder was much larger, and the amount of flux contained inside of the solder was adequate—mostly. Not so any more. Take another look at Figure 2. Those wetting problems suggest that not enough flux was present at the solder joint when the iron and solder were applied.

Figure 3: Kester’s no-clean model 951 Flux-Pen has a felt tip that puts the flux where you need it. (Image source: Kester)

Figure 3: Kester’s no-clean model 951 Flux-Pen has a felt tip that puts the flux where you need it. (Image source: Kester)

Back in the day, if you needed some extra flux, you added paste flux from a small tin of flux using a stubby little flux brush that was more at home in the plumbing section of a hardware store. It was messy and not too precise. Today’s smaller electronic components demand a better way to apply flux and we’ve got one: the flux pen. I use Kester’s no-clean model 951 Flux-Pen®and can recommend it highly (Figure 3).

Next, you need ways to remove excess solder, and there are two inexpensive tools that I can recommend. The first is solder wick, which is a flat braid of bare copper or tinned wire used to mop up excess liquid solder. There are literally hundreds of choices here, and you’ll want solder wicks of several sizes for large and smaller, more precise cleanups. So instead of recommending one particular wick or one particular brand of solder wick, I suggest that you take a look at this DigiKey summary page of solder wicks. Start your wick collection with a narrow wick and a wider one.

For really large cleanups, you need a solder pump (also called a solder sucker). A solder pump is especially useful when you need to remove a soldered through-hole component from a board. There are electrically powered solder pumps with integrated irons, but for infrequent desoldering tasks, a hand pump like the inexpensive Aven Tools 17537 desoldering pump is very handy to have on the bench. Over time, I’ve learned that I prefer a smaller solder pump like the Aven 17537 that I can operate with one hand (Figure 4).

Figure 4: Aven Tools’ 17537 desoldering pump is great for large solder cleanups. (Image source: Aven Tools)

Figure 4: Aven Tools’ 17537 desoldering pump is great for large solder cleanups. (Image source: Aven Tools)

Finally, there’s the dexterity element to soldering. I’ve seen YouTube videos of people who can hold two wires or a board and a wire, a soldering iron, and a length of solder with just their two hands, and they manage to get a good solder joint as they use just two fingers to feed exactly the right amount of solder into the joint. I’m not that dexterous, so I’ve resorted to a handy, inexpensive tool called a third hand to do my holding for me. I use an Aven Tools model 26000 Helping Hands Magnifier with Clamps to hold various bits and pieces together while I solder them (Figure 5).

Figure 5: Aven Tools’ model 26000 Helping Hands Magnifier with Clamps truly does give you a helping hand while soldering. (Image source: Aven Tools)

Figure 5: Aven Tools’ model 26000 Helping Hands Magnifier with Clamps truly does give you a helping hand while soldering. (Image source: Aven Tools)

Aven’s Helping Hands tool takes little room on the bench, is infinitely adjustable, and the magnifier is useful for my older eyes. In addition, the alligator clips that hold the work do double duty as heatsinks that prevent the heat of soldering from traveling farther down the wire. I’ve melted plastic insulating sleeves and burned my fingers when I’ve lingered for too long while heating a solder joint. The Helping Hands’ clamps help to prevent this problem.

A good soldering station and these four inexpensive tools will make soldering a much easier task in my experience. So those are my recommendations; what are yours? Please feel free to leave your comments below.

Have questions or comments? Continue the conversation on TechForum, DigiKey's online community and technical resource.

Visit TechForum

Steve Leibson was a systems engineer for HP and Cadnetix, the Editor in Chief for EDN and Microprocessor Report, a tech blogger for Xilinx and Cadence (among others), and he served as the technology expert on two episodes of “The Next Wave with Leonard Nimoy.” He has helped design engineers develop better, faster, more reliable systems for 33 years.

Steve Leibson was a systems engineer for HP and Cadnetix, the Editor in Chief for EDN and Microprocessor Report, a tech blogger for Xilinx and Cadence (among others), and he served as the technology expert on two episodes of “The Next Wave with Leonard Nimoy.” He has helped design engineers develop better, faster, more reliable systems for 33 years.