Enhancing LPWAN IoT Device Lifespan: Technical Strategies for Better Battery Management

For IoT devices operating in Low Power Wide Area Networks (LPWAN), battery life is a crucial consideration, especially when these devices are deployed in remote or hard-to-reach locations. However, the question is… What strategies can help maximize battery life for these IoT devices?

To explore these strategies, this article will introduce a real-world scenario based on a fictional company Y. In this scenario, the focus will be on optimizing the battery life of Y’s sensors by addressing common challenges faced during the development of battery-driven IoT sensors.

Scenario: Battery Optimization Challenges

Company Y designs battery-powered environmental sensors used for monitoring air quality, temperature, and humidity in remote forested areas. These sensors connect via LoRaWAN and need to last for several years without frequent battery replacements due to the high cost and difficulty of accessing remote sites. During product development, company Y faced several challenges: inconsistent battery life estimations, rapid power drain during data transmission, and variations in battery performance under different environmental conditions.

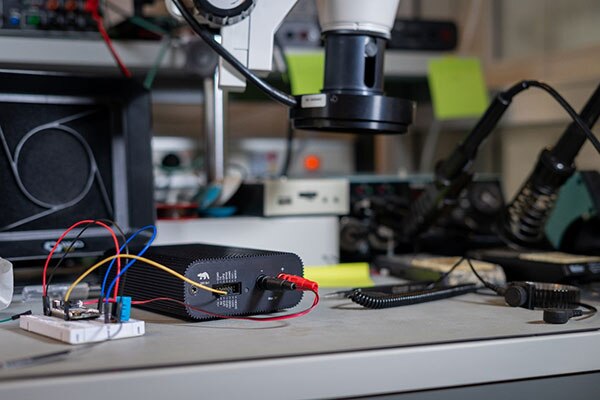

Otii Product Suite | Compact & portable power measurements for office, lab and field testing. (Image source: Qoitech)

Otii Product Suite | Compact & portable power measurements for office, lab and field testing. (Image source: Qoitech)

1. Identifying Key Factors Affecting LPWAN Battery Life

To address these issues, company Y began by understanding the factors influencing battery life, including power consumption during different device states, network connectivity requirements, and the impact of environmental variables.

Real-World Measurements vs. Theoretical Calculations

Y’s initial approach involved using theoretical calculations to estimate battery life based on datasheet values. However, when measuring power consumption using tools like the Otii instruments, they found discrepancies between theoretical and actual consumption. As an example, a sensor transmitting data every hour at 100 mW consumed 30% more energy during poor network conditions than under optimal conditions, due to retransmissions and longer connection times. Power profiling showed the need for adaptive transmission power adjustments to optimize battery life, reducing unnecessary power consumption by 20%.

Otii Product Suite | Otii Instrument . (Image source: Qoitech)

Otii Product Suite | Otii Instrument . (Image source: Qoitech)

2. Implementing Power Management Techniques for Optimal Battery Life

Company Y applied various power management strategies focusing on minimizing energy use during idle periods and data transmission.

Power Management Steps and Results

- Dynamic Transmission Power Adjustment: Company Y adopted a strategy to adjust the device’s transmission power based on signal quality and distance from the base station. For devices located closer to the base station, transmission power was lowered, reducing the overall power consumption and extending battery life.

- Optimized Sleep Mode: The sensors spent most of their time in deep sleep mode, only waking up for data collection and transmission. The firmware was configured to dynamically adjust sleep durations depending on the significance of the data, such as during rapid temperature changes. This adjustment significantly decreased the average power consumption during idle periods.

- Reducing Active Time During Transmission: By optimizing the communication protocol to compress data packets and reducing the frequency of status updates, company Y managed to cut down the power used during transmissions, contributing to more efficient energy usage.

Otii Product Suite | Otii Ace Pro | Power Box setting measuring current, power, and voltage channels. (Image source: Qoitech)

Otii Product Suite | Otii Ace Pro | Power Box setting measuring current, power, and voltage channels. (Image source: Qoitech)

3. Selecting the Right Battery for Harsh Conditions

For IoT devices like company Y’s environmental sensors, which operate in outdoor settings with fluctuating temperatures, choosing the right battery is essential for reliable performance and extended lifespan. The key factors to consider are electrochemistry, capacity, energy density, voltage and discharge characteristics, temperature range, device shelf life, and cost and lifespan. By evaluating these factors, engineers at Y ensure a reliable and long-lasting power supply for their IoT devices, contributing to the overall success of their deployments.

4. Four Steps for a Successful IoT Battery Selection Process

Following a structured battery selection process was crucial for company Y to optimize battery life effectively. These are the four steps followed:

#1) Define the Use Case: Company Y established that the primary use case involved continuous environmental monitoring in varying outdoor conditions, requiring robust batteries with high energy density and temperature resilience.

#2) Power Profiling: Using the Otii Battery Toolbox, company Y conducted power profiling for different device activities, such as data transmission, active sensing, and deep sleep. The profiling data showed that 80% of power consumption occurred during transmission, prompting further optimization and iterations of the firmware and application software.

#3) Creating Battery Profiles: Battery profiles were created based on real-world use case scenarios, including varying temperatures and load conditions. This highlighted differences in available capacity between different brands and chemistries, especially under high-current draw situations.

#4) Emulating Battery Performance: Using the Otii Ace Pro, company Y replayed battery profiles to emulate real-world conditions. Testing revealed that, depending on the load, the actual usable capacity of some battery brands was as low as 60% of the datasheet capacity, underscoring the importance of detailed profiling.

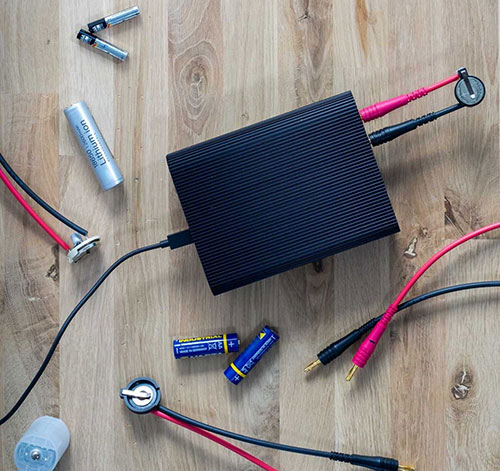

Otii Product Suite | Battery profiler setup. (Image source: Qoitech)

Otii Product Suite | Battery profiler setup. (Image source: Qoitech)

5. Profiling and Emulating Battery Chemistries

In Profiling different battery chemistries: A case study, Qoitech conducted a detailed comparison of various battery chemistries using Otii Ace Pro and Otii Battery Toolbox. Company Y applied these methods to assess how different batteries would perform in their devices.

Profiling Results for Realistic Battery Capacity Estimates

- Lithium-Manganese Batteries: Profiling three samples of the Saft LM17500 revealed an average capacity of 3050 mAh at room temperature, which was slightly higher than the datasheet value. Under cold conditions, the capacity dropped by only 10%, indicating strong temperature resilience.

- Alkaline Batteries: Variations in capacity across brands were significant, with AAA batteries ranging from 1080 mAh to 1150 mAh and AA batteries between 2420 mAh and 2730 mAh. Alkaline batteries showed up to a 35% capacity reduction at 0°C, making them less suitable for cold-weather deployments.

- Emulating Battery Profiles: By replaying the battery profiles using the Otii Ace Pro, company Y was able to predict the shutdown behavior of the device under different battery conditions. This emulation approach allowed for accurate estimations of device lifecycles in various scenarios, ensuring reliable power management planning.

Otii Product Suite | Battery Toolbox | Battery Emulation. (Image source: Qoitech)

Otii Product Suite | Battery Toolbox | Battery Emulation. (Image source: Qoitech)

Conclusion: A Comprehensive Approach to Optimizing LPWAN Battery Life

Company Y’s journey highlights the critical importance of a systematic, technical approach to maximizing battery life in LPWAN IoT devices. Validating batteries under real-world conditions - accounting for actual power consumption patterns, environmental factors, and operational behaviors - ensures that devices are tested in scenarios that truly reflect their intended use. This approach goes beyond theoretical estimations and datasheet values, focusing instead on optimizing power management, fine-tuning energy-saving techniques, and thoroughly selecting and profiling batteries.

By following these practices, developers can significantly improve the overall performance and lifespan of IoT sensors, ensuring reliable and efficient operation even in challenging environments.

Have questions or comments? Continue the conversation on TechForum, DigiKey's online community and technical resource.

Visit TechForum