Designing an Open Source Ventilator Project

Medical equipment availability issues related to the COVID-19 Pandemic highlight the need for broader involvement in medical device development by both individuals and the overall electronics industry. A relatively small number of traditional ventilator manufacturers combined with supply chain disruptions continues to impact the medical industry’s ability to increase ventilator manufacturing capacity. To combat this, many non-medical manufacturing companies are stepping up to shift manufacturing capacity to build ventilators. Additionally, multiple companies and individuals are working to develop and promote open source ventilator technology as a means to improve patient access to ventilators globally.

Ventilators and COVID-19

Patients acutely affected by the Coronavirus can require respiratory support. Those severely affected may develop Acute Respiratory Distress Syndrome (ARDS). ARDS is the inability of the lungs to absorb adequate oxygen on their own. ARDS patients suffer a higher mortality and can require several days of mechanical ventilation during treatment. The COVID-19 pandemic has led to dramatic increases in patients needing respiratory care. In many parts of the world the high cost or lack of ventilators continues to limit patient access to treatment and results in unnecessary death.

Ventilator Background

The role of the mechanical ventilator is to move gas in and out of the lungs to provide oxygen and remove carbon dioxide. Modern ventilators use positive pressure ventilation (PPV) to push gas into the lungs at a regular respiratory rate. Figure 1 shows an example simulation profile of the pressure ramps and flows for a mechanical ventilator during inhalation and exhalation. A ventilator implements this type of profile with various limits and rates when used to treat a patient.

Figure 1: Ventilator Waveform. (Image source: Trinamic)

Figure 1: Ventilator Waveform. (Image source: Trinamic)

Ventilators typically use pneumatic or electric power to provide the pressure and flow used during ventilation. Various sensors and controls within the mechanical ventilator are used to cycle between inspiratory (inhale) and expiratory (exhale) modes. Reference 1, Equipment in Anaesthesia and Critical Care: A complete guide for the FRCA, provides good background information and a baseline reference in understanding basic ventilator design and terminology.

Trinamic Open Source Ventilator (TOSV) Project

Trinamic (now part of Maxim Integrated) has a long history and years of experience in motion control electronics. In addition to supporting ongoing customer related ventilator projects, Trinamic wants to inspire engineers and medical companies by providing an open source hardware reference design for ventilators.

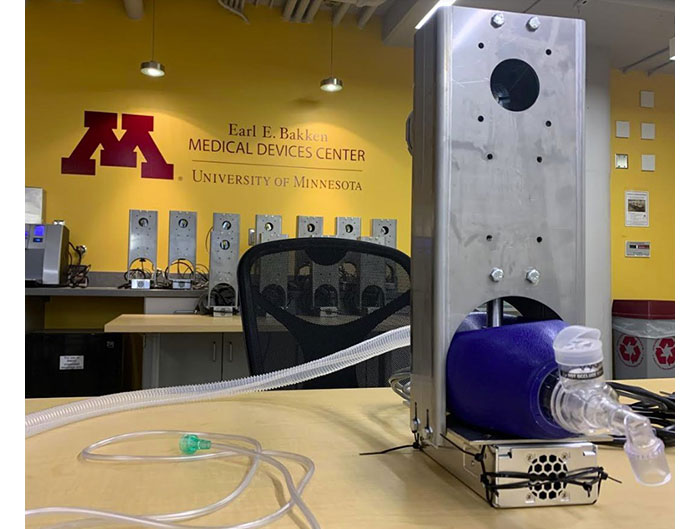

Many ventilators utilize a high RPM centrifugal turbine fan driven by a BLDC motor in combination with various sensors to provide pressure and flow-controlled ventilation modes. Because of experience working with low-induction BLDC motors, Trinamic adopted this approach as well, resulting in the public TOSV (Trinamic Open-Source Ventilator) project. Trinamic developed a proof of concept design (Figure 2) based on TMC4671 motor control and TMC6100 gate driver ICs driving a CPAP turbine fan.

Figure 2: Proof of Concept. (Image source: Trinamic)

Figure 2: Proof of Concept. (Image source: Trinamic)

Using the TMC6100+TMC4671-EVAL-KIT evaluation platform allowed the Trinamic team to develop firmware and quickly get the proof of concept up and running with a CPAP turbine. The kit is a set of one MCU Landungsbrücke board, two Eselsbrücke bridge boards, one TMC4671-EVAL motion controller board, as well as one TMC6100-EVAL driver board. The boards plug together providing easy access to electrical connections needed for controlling the motor and interfacing with sensors.

While developing firmware on the evaluation platform, another engineering team developed a small form factor custom PCB containing the TMC4671, TMC6100, microcontroller and interface circuitry. The resulting hardware and firmware developed by Trinamic’s engineering teams became the TOSV project (Figure 3).

Figure 3: Block Diagram TOSV Reference Design. (Image source: Trinamic)

Figure 3: Block Diagram TOSV Reference Design. (Image source: Trinamic)

TOSV’s goal is to provide a hardware design reference for control of the blower and sensors as well as firmware for basic ventilator functions. Figure 3 shows the major functional blocks implemented in the design. The footprint of the PCB was designed to plug into a Raspberry Pi, providing a readily available single-board computer platform for developing system level functionality.

The resulting TMC4671+TMC6100-TOSV-REF TOSV reference design evaluation board and firmware are available. TOSV reference design collateral includes schematics, PCB documentation, BOMs, CAD drawings, firmware, and Python user interface examples. All collateral can be accessed on Trinamic’s TrinamicOpenSourceVentilator-TOSV GitHub link.

Conclusion

The TOSV project is a good example of open source hardware and firmware being developed for the greater good to benefit all. By leveraging their experience with driving high RPM BLDC motors and applying it to a ventilator system, Trinamic has developed hardware and firmware reference blocks for both individuals and companies to use, develop with and modify.

References:

1 – Aston D, Rivers A, Dharmadasa A: Equipment in Anaesthesia and Critical Care: A complete guide for the FRCA.Royal College of General Practitioners.2013. Reference Source

Have questions or comments? Continue the conversation on TechForum, DigiKey's online community and technical resource.

Visit TechForum